Dry Screw Vacuum Pumps & Vacuum Hardening furnace : The Clean Core of Automotive Heat Treatment

— Driving Heat Treatment Processes Toward a Cleaner, More Efficient, and Greener Future

1. Vacuum Hardening: The Core Process of Automotive Heat Treatment

1.Brief description

Meaning: In simple terms, a hardening furnace is a magical tool used to “transform” metals

Function: By heating and rapid cooling, metals become harder and more wear-resistant

Application: For example, hard-core products such as automotive parts, cutting tools, and bearings cannot do without quenching furnaces

2.Working principle

The working process of a hardening furnace can be divided into three steps: heating → insulation → cooling

(1) Heating

Put the metal material into the furnace and heat it to a certain temperature (for example, steel must be heated to above 800°C).

This temperature is called the “Austenitizing temperature” and its purpose is to make the internal structure of the metal uniform.

(2) Insulation

After heating to the target temperature, keep it for a period of time to allow the heat to fully penetrate into the material.

The insulation time depends on the thickness and type of the material. If it is too short, the effect is not good, and if it is too long, it wastes energy.

(3) Cooling

This is the most critical step. The heated material is quickly placed in a cooling medium (water, oil or air).

Rapid cooling will change the internal structure of the metal, making it harder and more wear-resistant.

3.Advantages

Temperature control: A good hardening furnace can accurately control the temperature, with a temperature difference of no more than ±5℃, ensuring that each piece of material can be heated evenly

Cooling system: The cooling speed must be fast and even, otherwise the material will easily deform or crack

Atmosphere control: Some high-end hardening furnaces can also control the atmosphere in the furnace to prevent material oxidation and ensure surface finish

4.Hardening furnace vs. other heat treatment equipment

(1) Annealing furnace: Slow cooling after heating to soften the material and make it easier to process

(2) Tempering furnace: Reheating after quenching to reduce brittleness and improve toughness

(3) Hardening furnace: Rapid cooling, focusing on the word “hard”

5.Application scenarios of Hardening furnaces

(1) Automobile manufacturing: Engine parts, gears, and bearings all require hardening

(2) Tool manufacturing: Cutting tools, drills, and scissors are more durable after hardening

(3) Aerospace: High-strength alloy materials, more stable performance after hardening

(Figure: Vacuum furnace is for reference only)

2. The Critical Role of Dry Screw Pumps in Vacuum Systems

1.Overview

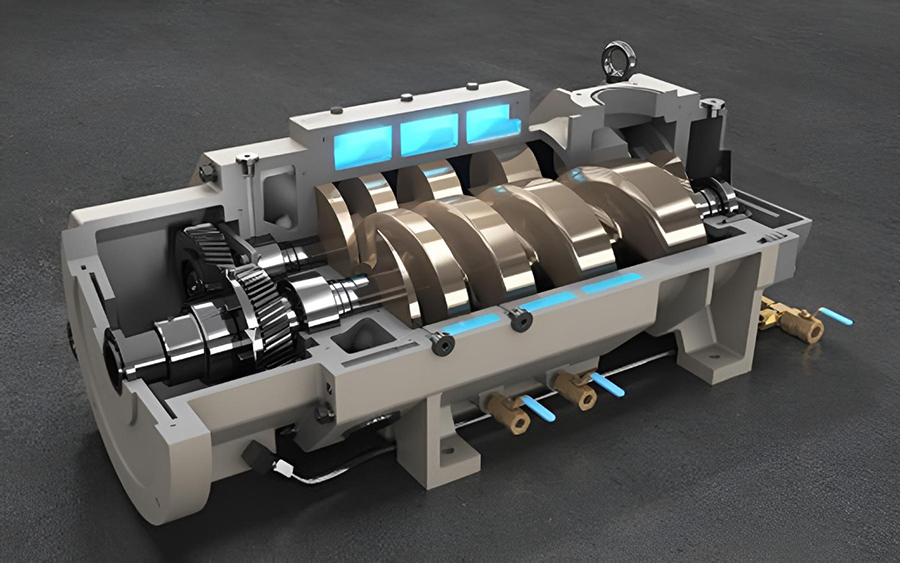

Dry screw vacuum pump is an efficient and environmentally friendly vacuum acquisition equipment. Its core technology is to achieve gas suction, compression and discharge through the synchronous counter-rotation of a pair of precision screws. It is widely used in semiconductor, chemical, pharmaceutical, vacuum coating and other fields.

(Figure: Internal structure of EVP dry screw pump)

2.Advantages of dry screw pump

(1) The ultimate vacuum is 5Pa. A single pump can achieve the effect of a dry vacuum unit. (Economical and practical)

(2) No working fluid is required in the pump chamber, which solves the problem of emulsification and deterioration of the working fluid, avoids the replacement of working fluid, cleaning and maintenance of parts in the pump chamber and waste oil treatment, and has low maintenance costs. (Environmentally friendly)

(3) It is less affected by cooling water, has low cooling water requirements and small water volume. (Water saving)

(4) The screw rotor inside the pump chamber has no contact and no friction; (Long life)

(5) The gap inside the pump chamber is sealed, there is no risk of emulsification of the working fluid, and the performance is stable and vacuum; (Wide application)

(6) The pumped solvent is pollution-free, and the solvent can be efficiently recovered after the pump, eliminating the need for tail gas treatment; (High efficiency)

(7) Zero sewage, zero waste oil, zero oil fume emissions, and no environmental pressure; (Zero emissions)

(8) No special maintenance is required on a daily basis, and there is basically no maintenance cost, which saves trouble and worry; (Low maintenance)

3.Application of dry screw pumps in vacuum quenching systems

(1) Pre-pumping stage: quickly pump the furnace chamber to the working vacuum degree

(2) Pressure holding stage: maintain a stable low pressure to avoid oxidation and pollution

(3) Cooperate with the back-stage pump: provide front-stage suction for the diffusion pump or molecular pump

(Figure: EVP series dry screw vacuum pump: oil-free, corrosion-resistant, easy to maintain)

3. Advantages of Dry Screw Pumps in Heat Treatment

1.Oil-free and clean, meeting high-quality heat treatment requirements

Traditional oil pumps may have oil vapor reflux at high temperatures, polluting the furnace chamber and affecting the Hardening effect. Dry screw pumps are completely oil-free and lubricated, ensuring zero oil mist pollution in the entire Hardening environment. They are ideal for high-cleanliness heat treatment processes such as automotive gears and motor shafts.

2.High water vapor and gas handling capacity to ensure process stability

During the heating and insulation process, the workpiece will release a large amount of gas (including water and hydrocarbons). The dry pump can stably handle mixed gases containing water, oil, and particles without emulsification or jamming, ensuring stable pumping speed and vacuum.

3.Wide pressure working range, no intermediate pump required

Dry pumps can directly pump from atmospheric pressure to below 10⁻² Torr, directly as the front pump of a diffusion pump or molecular pump, simplifying the system structure and saving cost space.

4.High reliability, supporting 24-hour continuous production

Screw pumps have a simple structure, low failure rate, and long life, which are very suitable for continuous operation of vacuum heat treatment production lines. No frequent maintenance or lubricant replacement is required, which greatly reduces operating costs.

4. Typical Heat Treatment Configurations in Automotive Plants

As the global manufacturing industry develops towards low-carbon and intelligent development, vacuum heat treatment equipment also needs to be upgraded synchronously:

(1)Dry pump system will become the standard configuration of heat treatment

(2) Intelligent systems that support remote control and predictive maintenance will be widely deployed

(3) The coordinated development of processes and materials (such as magnetic materials, light alloys, etc.) will promote the continuous expansion of dry pump applications

|

Application parts |

Components |

Heat treatment method |

Vacuum system configuration |

|

Transmission |

Precision gears, synchronizer rings |

Vacuum hardening + tempering |

Dry screw pump + diffusion pump |

|

Electric drive system |

Motor shaft, rotor |

Gas hardening |

Single screw pump system |

|

Chassis parts |

Brake disc, connecting rod, shock absorber rod |

Vacuum high temperature tempering |

Dry pump + molecular pump |

(Figure: the common configuration of automobile heat treatment site – for reference only)

Conclusion

Dry screw pumps are becoming an irreplaceable core equipment in automotive vacuum heat treatment processes. EVP will continue to provide professional vacuum technology services to help customers build cleaner, more efficient and more reliable heat treatment systems.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)