Aluminum vacuum brazing vacuum system

Aluminum vacuum brazing furnace body is composed of heating chamber, furnace, furnace front and back door, and various functional components. The heating chamber, stalled in furnace, is made up of a plurality of heating resistors and insulating layer. Heating resistors are connected with electrodes and cables outside of furnace and form 28 heating cells, which are supplied with power by one controllable silicon voltage power supply circuit. Furnace has a double-water-cooling jacketed structure and is welded with requested functional components. Furnace front and back door also have a double-water-cooling jacketed structure. They are installed on furnace door cars which could move in the vertical direction of furnace body, and they could be moved by the cylinder drive in the furnace door cars along the axis direction of furnace body. These moves in two direction could open or shut down furnace doors.

Aluminum vacuum brazing furnace mechanical structure

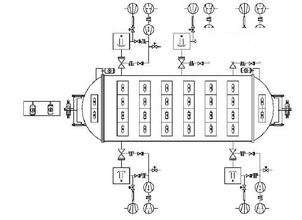

Aluminum vacuum brazing is fastidious about vacuum system. Aluminum vacuum brazing vacuum system not only has the ability get a strong enough vacuum, but also has the capability to maintain the vacuum above 10-3Pa even when a large number of gas volatilize in the furnace in the heat preservation before brazing and last soldering heat preservation, which require this vacuum system have a fast and stable pumping speed. There are five vacuum systems for aluminum vacuum brazing, and each vacuum system requires high vacuum oil diffusion vacuum pump and some mechanical pumps. Oil diffusion vacuum pump works as a main car it has a fast pumping speed and high ultimate pressure. Mechanical pumps, as a backing pump of oil diffusion vacuum pump, are usually composed of roots vacuum pumps and rotary piston vacuum pumps. Besides, rotary vane vacuum pumps are used as maintaining pumps. It could ensure vacuum in the pump body when oil diffusion vacuum pump begins to preheat before the whole vacuum system starts, and also avoids the oxidizing of diffusion vacuum pump oil when oil diffusion vacuum pump gets into the cooling process after work and roots vacuum pumps and rotary vane vacuum pumps are shut down in order to save energy. Valves in every vacuum system contain large valves, backing valves, pre-pumping valves and discharge valves.

Water cooling system is designed to cool brazing furnace wall, oil diffusion pumps, roots vacuum pumps, rotary piston vacuum pumps and rotary vane pumps. Main water inlet is equipped with a pressure gauge. When water pressure is insufficient, it alarms. Water in different pipes after being cooled return to the main water return channel which is connected with the main water return pipe. This system has inert gas nozzles, manual ball-type valve and manual needle valve. If necessary, nitrogen in the furnace could be substituted in the pre-vacuum phase.