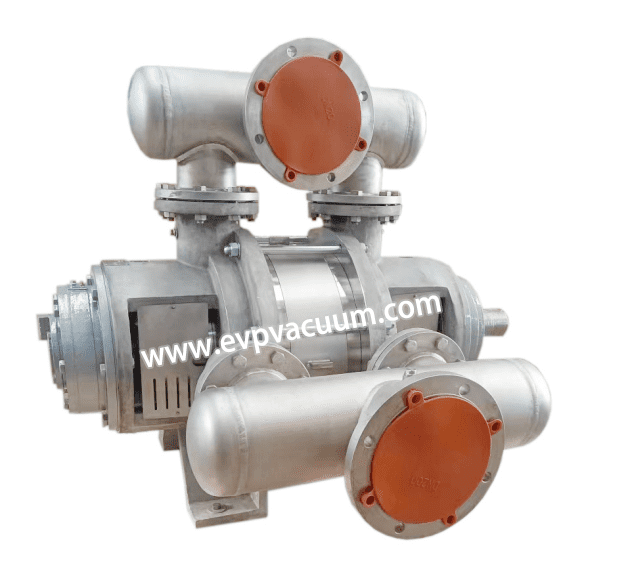

Electrolytic cell compressor

Electrolytic cell compressor: a key equipment in the electrolysis water hydrogen production system

Electrolytic cell compressor of working principle

The electrolytic cell compressor is one of the key equipment in the electrolytic water hydrogen production system. Its main function is to compress the hydrogen gas produced by electrolysis to meet the needs of subsequent use or storage. Specifically, compressors increase the pressure of hydrogen gas to make it easier to store and transport. At the same time, the compression process also helps to increase the energy density of hydrogen, making it more advantageous in practical applications.

In the electrolysis water hydrogen production system, the compressor is usually connected to equipment such as electrolysis tanks and hydrogen storage tanks. The hydrogen gas generated by the electrolytic cell enters the compressor through the pipeline, and after compression, it is transported to the hydrogen storage tank or other places of use. In this way, the entire process of electrolyzing water to produce hydrogen forms a complete cycle.

Electrolytic cell compressor of performance parameters

The performance of the electrolytic cell compressor directly affects the efficiency and stability of the electrolytic water hydrogen production system. Therefore, when choosing a compressor, it is necessary to fully consider its performance parameters, reliability, maintenance costs, and other factors.

1. Compression ratio

Compression ratio refers to the ratio of the outlet pressure to the inlet pressure of a compressor. The higher the compression ratio, the higher the compression efficiency of the compressor. Generally speaking, the compression ratio of the electrolytic cell compressor should be between 2-3.

2. Traffic

Flow rate refers to the volume of hydrogen gas compressed by a compressor per unit time. The larger the flow rate, the higher the working efficiency of the compressor. Generally speaking, the flow rate of the electrolytic cell compressor should be between 100-500 cubic meters per hour.

3. Pressure

Pressure refers to the pressure at which the compressor outputs hydrogen gas. The higher the pressure, the higher the energy density of hydrogen, but it also increases the energy consumption and maintenance costs of the compressor. Generally speaking, the pressure of the electrolytic cell compressor should be between 20-30 MPa.

Electrolytic cell compressor of maintenance and upkeep

The maintenance of the electrolytic cell compressor is crucial for ensuring its long-term stable operation. Here are some common maintenance measures:

1. Regularly replace the filter element

The filter element is an important component in the compressor, which can effectively filter impurities and moisture in hydrogen gas. Regularly replacing the filter element can ensure the purity of hydrogen and the normal operation of the compressor.

2. Regularly check the lubricating oil

Lubricating oil is an important lubricating component in compressors, which can reduce friction and wear, and extend the service life of compressors. Regularly check the quality and quantity of lubricating oil, and replace and add lubricating oil in a timely manner.

3. Regularly clean the compressor

Impurities and moisture in hydrogen gas are prone to accumulate inside the compressor, and long-term lack of cleaning can affect its normal operation. Regularly cleaning the interior of the compressor can ensure its long-term stable operation.

In short, the electrolytic cell compressor is an indispensable part of the hydrogen production system through electrolysis of water. When selecting and using compressors, it is necessary to fully consider factors such as their performance and maintenance costs to ensure the efficiency and stability of the entire electrolytic water hydrogen production system. At the same time, regular inspection and maintenance of the compressor is also an important measure to ensure its long-term stable operation.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)