Brand: EVP

Classification: Vacuum Pump

Availability : In Stock

Giq-a series pneumatic high true valve butterfly valve is suitable for connecting or stopping air flow in high vacuum system.

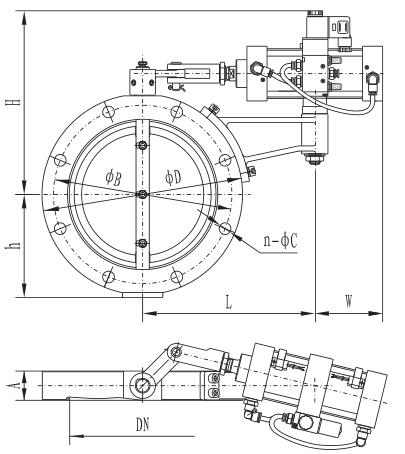

| model | Drift diameter(DN) | ΦD | ΦB | H | h | A | L | W | n-ΦC |

| GIQ-50A | 50 | 110 | 90 | 162 | 55 | 26 | 160 | 62 | 4-Φ9 |

| GIQ-63A | 63 | 130 | 110 | 172 | 66 | 32 | 180 | 81 | |

| GIQ-80A | 80 | 145 | 125 | 178 | 74 | 8-Φ9 | |||

| GIQ-100A | 100 | 165 | 145 | 187 | 84 | ||||

| GIQ-125A | 125 | 200 | 175 | 208 | 102 | 35 | 207 | 86 | 8-Φ11 |

| GIQ-150A | 150 | 225 | 200 | 220 | 114 | ||||

| GIQ-200A | 200 | 285 | 260 | 256 | 146 | 45 | 236 | 100 | 12-Φ11 |

| GIQ-250A | 250 | 335 | 310 | 282 | 173 | 50 | |||

| GIQ-300A | 300 | 425 | 395 | 350 | 216 | 55 | 280 | 118 | 12-Φ14 |

| GIQ-400A | 400 | 510 | 480 | 392 | 259 | 60 | 304 | 130 | 12-Φ14 |

| GIQ-500A | 500 | 600 | 565 | 440 | 312 | 80 | 350 | 175 | 12-Φ18 |

| GIQ-600A | 600 | 710 | 670 | 525 | 366 | 100 | 360 | 212 | 12-Φ21 |

| GIQ-800A | 800 | 920 | 880 | 690 | 473 | 130 | 520 | 268 | 12-Φ21 |

Giq-a series pneumatic high true valve butterfly valve is suitable for connecting or stopping air flow in high vacuum system. The valve plate of the valve adopts the clamping structure to clamp the sealing ring of the valve plate, which has the function of fine-tuning the main sealing. The valve is powered by compressed air, changes the direction of the air path through the electromagnetic reversing valve, and performs the cylinder pushing, so that the valve plate fixed on the rotating shaft rotates 90 ° to realize the opening and closing of the valve.

The applicable working medium is air and non corrosive gas.

| applicability(Pa) | 105 ~1.3×10-6 |

| Valve leak rate(Pa.L/S) | ≤1.3×10-7 |

| Applicable temperature(℃) | -25~+80(sealing material is NBR) |

| -30~+150(sealing material is fluororubber) | |

| Material of main parts of valve | Stainless steel or carbon steel |

| Air source pressure(MPa) | 0.4~0.8 |

| Flange standard | GB/T6070 |

| Installation position | arbitrarily |

| supply voltage | Standard delivery:AC220V/50Hz |

| Special designation:①AC110V;②DC24V;③DC12V | |

| signal feedback | Standard delivery: without feedback signal |

| Special designation: magnetic switch DC/AC 5~240V |

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.