Brand: EVP

Classification: Vacuum Pump

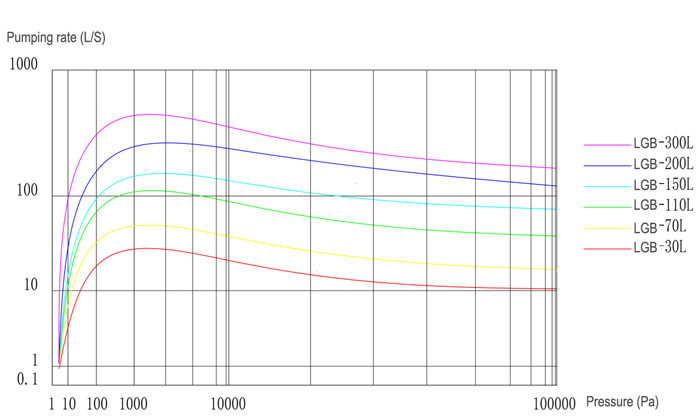

SUCTION CAPACITY: 30L/S TO 300L/S

VACUUM RANGE: 10PA

Availability : In Stock

Vertical structure, more smooth drainage, strong ability to pump condensable gas and gas-liquid mixture.

Technical parameter :

| Model | Pumping rate/L/s | Extreme vacuum/Pa | Full load power/Kw | input voltage/V | Noise/Db | Cooling water flow/L/h | Cooling water inlet temperature/℃ | Cooling water inlet pressure/Mpa | Intake port/mm | Exhaust port/mm | weight/kg |

| LGB-30L | 30 | 10 | 4 | 380 | 73 | 300 | ≤35 | 0.2-0.4 | DN40 | DN40 | 287 |

| LGB-70L | 70 | 10 | 7.5 | 380 | 75 | 650 | ≤35 | 0.2-0.4 | DN50 | DN40 | 630 |

| LGB-110L | 110 | 10 | 11 | 380 | 76 | 800 | ≤35 | 0.2-0.4 | DN65 | DN50 | 700 |

| LGB-150L | 150 | 10 | 15 | 380 | 76 | 800 | ≤35 | 0.2-0.4 | DN80 | DN50 | 896 |

| LGB-200L | 200 | 10 | 18.5 | 380 | 78 | 1000 | ≤35 | 0.2-0.4 | DN80 | DN50 | 936 |

| LGB-300 | 300 | 10 | 22 | 380 | 80 | 1200 | ≤35 | 0.2-0.5 | DN100 | DN80 | 1260 |

Performance curve :

Vertical screw pump Characteristic

1. With the most advanced variable pitch rotor, the energy consumption is reduced by 30%.

2. The ultimate vacuum degree can reach 3PA, and the pumping efficiency is high

3. The compound seal technology with invention patent is more reliable and has longer service life than mechanical seal.

4. The unique water-cooling structure makes the pump have excellent cooling effect and lower operating temperature

5. Vertical structure, more smooth drainage, strong ability to pump condensable gas and gas-liquid mixture

6. Vertical structure is adopted, which is easier to clean for the working condition with dust

7. High safety, no contact wear in internal design, no pollution of materials

8. Green environmental protection, no pollution, no pollution, no waste discharge treatment cost.

9. The working chamber and rotor surface are provided with anti-corrosion coating, which can adapt to severe working conditions .

Vertical screw pump Application

Chemical and pharmaceutical fields: molecular distillation, freeze-drying, drying, degassing, evaporation, distillation, filtration, organic solvent recovery, biotechnology

1) Polymerization ; 2) organic solvent recovery ; 3) dyes, coatings, adhesives; 4) Plastics and resins ; 5) grease chemistry ; 6) organosilicon oil ; 7) spice essence ; 8) vitamin, sugar ; 9) small test ; 10) Food ; 11) metal handling

Other fields: coating, impregnation, drying, degassing, crystal drawing, die casting, sterilization

1) Electronic ; 2) metallurgy ; 3) food and beverage ; 4) Solar energy ; 5) motor ; 6) parts processing

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.