helium leak detector in leak detection of fire equipment steel cylinders

The helium mass spectrometer leak detector has shown significant advantages and accuracy in the application of leak detection for fire equipment steel cylinders. The following is a specific explanation about its application:

The importance of leak detection for fire equipment steel cylinders

Fire equipment steel cylinders, as special equipment, play a crucial role in the event of a fire. However, due to the fact that these steel cylinders are usually idle and contain high-pressure fire extinguishing materials (usually up to 2.5 MPa) inside, if there is a leak in the cylinder (especially at the weld or valve), especially a small leak, it will pose a great safety hazard. Therefore, it is crucial to conduct strict leak detection procedures on steel cylinders before leaving the factory to avoid leaks during transportation or storage.

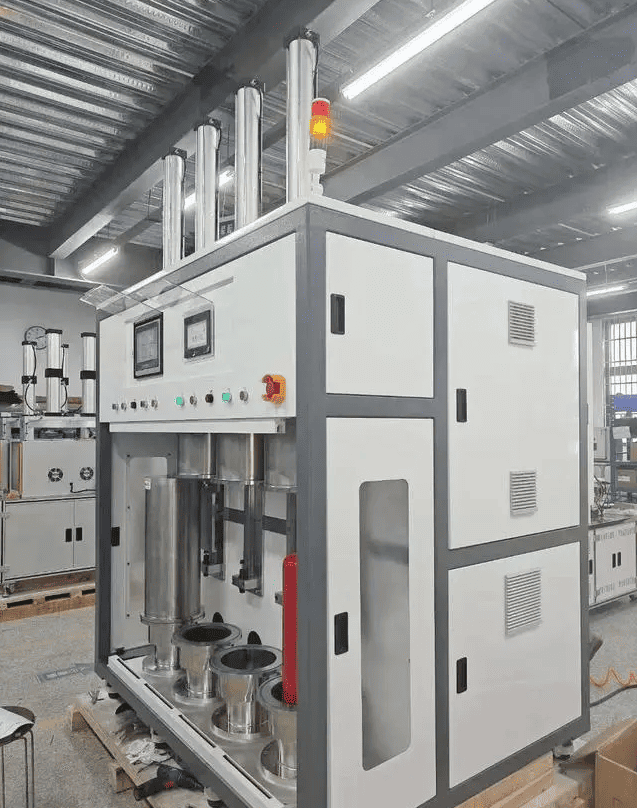

Fire extinguisher helium detection equipment

Traditional leak detection methods and their limitations

The traditional method of leak detection for fire equipment steel cylinders mainly uses the water inspection method, which is to pressurize the cylinder to about 2MPa and then place it in a water tank to observe whether there are any bubbles emerging. Although this method is simple and easy to implement, it can only detect larger leakage holes and is more difficult to detect small leaks. According to calculations, the leakage rate can only reach approximately 1.0 x 10 ^ -4 mbar I/s when the bubble diameter reaches 0.226mm and one bubble emerges per minute, which is clearly insufficient for small leaks.

Fire extinguisher helium detection equipment

Application of helium mass spectrometer leak detector

Working principle: The helium mass spectrometer leak detector is a gas tightness detection instrument based on the principles of mass spectrometry, using helium gas as the leak gas. It works through a mass spectrometry chamber consisting of an ion source, analyzer, collector, cold cathode ionization gauge, as well as an extraction system and electrical components. When helium gas enters the mass spectrometry chamber through a leak, it collides with electrons to produce ionization. The formed helium ions are deflected in a magnetic field and form specific orbits, ultimately reaching the receiving electrode and being detected.

Leak detection method: When using a helium mass spectrometer for leak detection of fire equipment steel cylinders, pressure mode is usually used. Firstly, fill the inspected steel cylinder with a certain amount of helium gas to create a pressure difference between the inside and outside of the cylinder. Then, use the suction gun of the leak detector to scan the welds and valves of the steel cylinder. If there is a leak in the steel cylinder, helium gas will leak out from the inside and be sucked in by the suction gun. When the leakage rate exceeds the set alarm value (usually 1.5 x 10 ^ -5 mbar I/s), the leak detector will issue an alarm signal.

Advantages: Compared with traditional water detection methods, helium mass spectrometer leak detectors have higher sensitivity and accuracy. It can detect smaller leakage holes and display the leakage rate in real time. In addition, it can accurately locate the leakage location, providing convenience for subsequent maintenance and replacement.

Helium mass spectrometer leak detector

summary

The helium mass spectrometer leak detector has shown significant advantages and effects in the application of leak detection of fire equipment steel cylinders. Through its high-precision and high-sensitivity detection capabilities, it can ensure the sealing and safety of fire equipment steel cylinders, providing strong protection for people’s lives and property safety.

The helium mass spectrometer leak detector has been widely used in many industries with excellent quality and stable performance, meeting various applications It can meet the requirements of single machine leak detection, and can also be integrated into leak detection systems or PLCs

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)