Helium mass spectrometer leak detector in pressure vessel vacuum

With the increase of pressure vessel export products and the attention of manufacturers to product quality, the application of helium mass spectrometer leak detector in the pressure vessel manufacturing industry in China is increasing year by year.

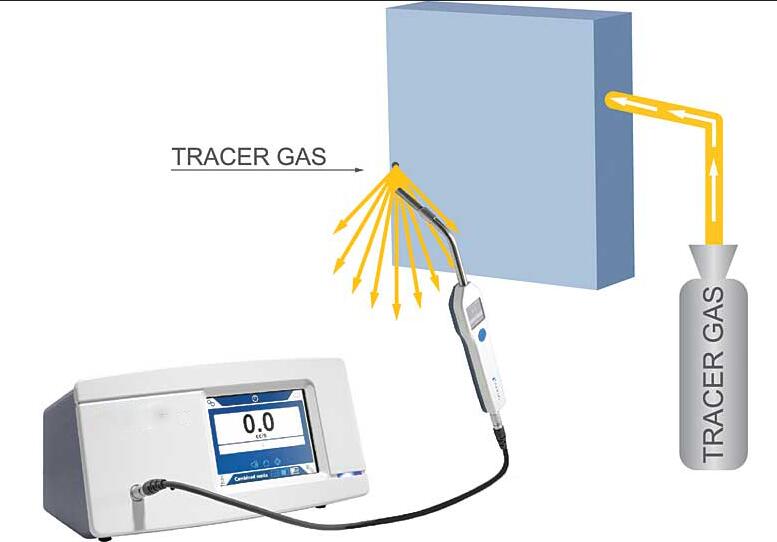

Helium mass spectrometer leak detection method (hereinafter referred to as helium detection) is usually applied to pressure vessels with high overall leak proof level due to its high sensitivity and accuracy. Helium detection method can be basically divided into two kinds: internal helium pressurization method and external helium application method. Because the latter needs to completely vacuumize the equipment, it often increases the cost of testing equipment (such as high and low pressure vacuum pump, vacuum valve, etc.) and equipment tooling (such as external pressure reinforcing ring), so this method is usually used for equipment with small volume and thick wall; For most pressure vessels, the former method is usually preferred.

Helium inspection is to detect the leakage through helium through the leakage hole, so if there is oil stain and welding slag on the weld surface, as well as the water and dirt inside the equipment, the leakage hole will be temporarily blocked, which will affect the test results. Therefore, before the test, the inside of the equipment must be cleaned and the weld surface must be cleaned, and the inside of the equipment must be dried with a hot air device.

A metal hose is used to connect the suction gun and the mass spectrometer leak detector. Helium mass spectrometer leak detector shall be used after calibration and calibrated every 1-2 hours during the leak detection. The leakage rate of helium mass spectrometer detector shall be 1-2 orders of magnitude higher than the allowable leakage rate of the equipment. First, place the equipment firmly in a bright and well ventilated place, connect the leakage detection pipeline and pressure gauge, and install the pressure gauge on the top of the leakage detection vessel for easy observation. Nitrogen or other inert gas can be used to increase the pressure of the equipment, and then pure helium or helium mixture can be used to increase the internal pressure of the test equipment to the test pressure, and at least 10% – 20% helium content should be contained in the equipment. The leakage test pressure shall not be higher than 25% of the design pressure of the equipment, but not lower than 0.103mp. After 30 minutes of pressure maintaining, the equipment shall be sucked by a suction gun with a scanning rate of no more than 25 mm / s or slower within the range of no more than 3 mm from the weld surface, and shall run from the bottom of the weld to the top.

When there are many welds or large testing area of tube plate, the part can be completely covered with plastic film and sealed with adhesive tape to make the leaked helium enter the cover. Make holes at different places of the plastic cover, record the initial readings before and after filling a certain amount of helium, then seal the holes, and record the new readings at the same position 1-2 hours later. If any leakage is found, check the welds one by one according to the above method until the leakage point is found.

matters needing attention

1. This test shall be carried out for the equipment after the completion of the construction work, and the weld repair and grinding shall not be carried out after the completion of the test.

2. If the equipment is soaked or there is residual liquid, it will affect the leakage of capillary and the authenticity of test results.

3. Since helium is lighter than air, pay attention to the sequence of leak detection. The inspection sequence should be from bottom to top, from near to far.

4. In the process of leak detection, if a large amount of helium is found to enter the mass spectrometer leak detector, the suction gun shall be removed immediately to prevent the test from being delayed because the instrument cannot remove the helium for a long time.

Helium mass spectrometer leak detector has the advantages of high accuracy, fast response, high security, wide adaptability, small size and portability, and easy to move, no matter in leak location or in leak test application. If you want to know about the application and technology of helium mass spectrometer leak detector, please feel free to contact us!

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)