How to choose butterfly valve correctly

Butterfly valve selection, first of all, according to the successful engineering practice, relevant laws and regulations, select the appropriate structure, material and pressure level to ensure the safety and reliability of butterfly valve.

butterfly valve type selection:

The flow characteristic of butterfly valve is approximate straight line, and the difference is not very big whether it is middle line or eccentric type. It is suitable to use medium line as regulating and small diameter process valve.

How to choose double eccentric butterfly valve and triple eccentric butterfly valve? These two structures have the characteristics of quick separation and closer closing. How to choose the two structures? As a soft seal, using double eccentric valve is more convenient in processing and manufacturing. The three eccentric machining is more complex, but it is more prominent that the closer it is closed, and it is not easy to produce interference, so it is more suitable for metal hard seal. At present, there is no comprehensive analysis in the market, and it is considered that it is wrong to recommend the use of triple eccentric metal hard seal in any case, especially in large diameter constant temperature water system. Because the replacement of hard metal seal ring is much more difficult than soft seal ring, soft seal should be used in large diameter hydraulic butterfly valve. Only those that are not easy to repair and replace and have high temperature, harsh working conditions, can not have to use metal hard seal. In order to replace the metal seal ring under harsh working conditions, the valve body is generally lengthened and a middle opening is opened to facilitate the disassembly of the seal ring.

Vacuum butterfly valve has two kinds of rubber soft seal and metal hard seal. It can be medium linear, eccentric and lever type in structure. Soft seal is generally required for high vacuum degree. A fixed temperature is required, only metal seal is used. In order to get a good effect, the surface that can be machined generally should be processed with good surface roughness and cleanliness. It is not allowed to paint or apply general antirust oil, only vacuum grease is allowed.

butterfly valve diameter selection:

The diameter selection of butterfly valve is mainly determined by the medium, flow rate or flow rate passing through the valve.

For liquid, the general velocity should not exceed 5m / s, and the maximum should not exceed 78m / s. Generally, the economic flow rate of water is 2 ~ 3m / s, the low pressure gas flow rate is recommended to be 2 ~ 10m / s, the medium pressure gas flow rate is recommended to be 10 ~ 20m / s, for the steam flow rate, the low pressure steam is recommended to be 20 ~ 40m / s, the medium pressure steam is 40 ~ 60m / s, and the high pressure steam is 60 ~ 80m / s.

Of course, sometimes in order to reduce the pressure loss, the valve is selected to be larger, so the flow rate is lower, but if you want to adjust in small flow, you can’t do so.

The phenomenon of rapid evaporation and re condensation of a liquid flowing through an area with very low absolute pressure in a very short period of time is called cavitation. This phenomenon cannot occur in the gas flow, because the state of the gas will not change under low pressure. When the fluid flows into the region with high pressure, the vapor bubble will suddenly condense, and the bubble will collapse or burst. The velocity of the explosion may reach 110 m / s and high pressure of 50 MPa, which will cause impact damage to the wall. In order to avoid cavitation, some measures should be taken.

① So that the flow rate is not large enough to produce such a low pressure;

② The atmosphere is introduced into the low pressure area;

③ Reduce the pressure difference △ PR ≤ F12 (inner 1-pv), where PV represents the pressure of the blocking flow on the contraction section.

When the pressure difference P < 1.5MPa, even if cavitation occurs, the material damage is not serious, so no special measures are needed.

Generally speaking, the harder the material is, the stronger the cavitation resistance is.

When the butterfly valve does not produce cavitation, the general cavitation coefficient g ≥ 2.5.

butterfly valve materials selection:

The main material of butterfly valve shall be determined according to the nature of medium, working temperature and flow condition (whether there are particles, two-phase flow, etc.). Under normal conditions, the user is required to put forward the main material of the valve, especially the main material of the valve for special or severe working conditions. In most cases, the valve body material is the same as or slightly higher than the pipeline material.

The temperature that steel valves can adapt to can be found in ANSI e16.34. Carbon steel is undoubtedly a general economic material. Its temperature resistance can reach 425 ℃. Cast iron and ductile iron are widely used in low-pressure valves.

For seawater resistant valves, due to different requirements, the following methods shall be adopted depending on working conditions and importance:

① It is made of titanium alloy;

② Duplex stainless steel is used;

③ Lining rubber or polytetrafluoroethylene is used;

④ Epoxy or ceramic coating

⑤ Low nickel cast iron or low alloy cast iron is used.

Sometimes the cross composite of the above materials is also used. Generally, titanium alloy should be used for light weight ships, while lining or low alloy nodular cast iron with coating should be used in ordinary power plants and chemical plants.

butterfly valve installation:

1. Direction. In theory, butterfly valve can be installed in any direction. It is recommended to install the valve shaft horizontally, so that the bearings at both ends will not be at the bottom (below), so as to prevent the sediment in the medium from entering the bearing.

2. Water inlet pipe configuration. There are elbows and T-pipes on the inlet side of butterfly valve, which cause the fluid to bend and distribute unevenly. When flowing into the valve, the biased flow will occur in the pipe. Therefore, the bias flow generated must be evenly distributed on both sides of the butterfly plate, so as to avoid uneven stress on both sides of the butterfly plate and may produce additional force moment.

3. Outlet pipe configuration. If on the pipeline, in order to not bear the axial force and bending moment on the valve, it is better to set expansion joint at the outlet side of the valve. When the valve is opened and closed, the water pressure of the valve should not be borne by the anchor, but through the flange of the valve and borne by the pipeline.

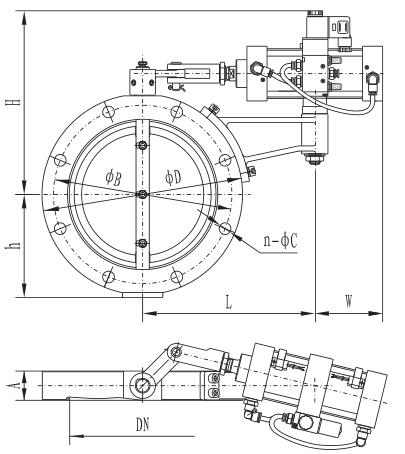

4. Generally, the structure length of butterfly valve is relatively short, and its butterfly plate will extend into the adjacent pipeline or other components, so it is necessary to pay attention to avoid collision and interference with other parts. Moreover, it is necessary to prevent the inner diameter error of the matching pipe larger than C and collide with the butterfly plate.

Butterfly valve as a regulator is nothing more than regulating the flow and pressure. The adjustment of the valve is realized through the loss of pressure.

The relation curve of flow rate and angle of butterfly valve is like an integral symbol, belonging to parabola type. When the opening of butterfly plate is greater than 60 °, the change of flow rate is small when the angle is increased. Similarly, when the disc angle is less than 15, there is a similar situation.

In order to achieve good regulation effect, we should pay attention to the following points:

a. The loss of control valve accounts for at least 1 / 3 of the system;

b. In order to achieve good regulation effect, the diameter of the valve is usually smaller than that of the matching pipe;

c. According to experience, the size of the valve should be determined to make the flow rate of the valve reach 5m / s.