How to use roots blower in sulfuric acid

Roots blower is a positive displacement fan, which has the characteristics of low noise, high energy saving, high efficiency and good air tightness. Roots blower has been widely used in sulfuric acid process.

Roots blower combines the advantages of reciprocating compressor and centrifugal blower. Based on them, the relationship between speed and air pressure is improved. Under the condition of constant speed, the air pressure slightly changes and the air supply volume remains unchanged, and the air volume is proportional to the speed.

The disadvantage of Roots blower is that when the fan outlet is blocked, it is easy to cause pressure rise and cause damage to the machine. If it is used for a long time, the gap between the two rotors and between the rotor and the casing will expand, resulting in the decrease of the air supply volume.

In the case of Roots blower, a pair of cast steel (or cast iron) rotors are respectively installed on two parallel shafts. The synchronous gear at the end of the rotor shaft keeps the two rotors engaged and driven. Therefore, when the fan is working, the two rotors rotate at the same speed in the opposite direction to extrude the gas between the rotor and the casing. In the direction of gas inlet and outlet, the pressure difference between the upper part and the lower part can be used to offset part of the weight of the rotor and shaft, so as to reduce the pressure on the bearing and reduce the wear.

The shape curve of Roots blower rotor is composed of cycloid. The long diameter is determined by the air volume delivered, while the short diameter is mainly determined by the power required. That is, after the main shaft diameter is determined, the short diameter is determined according to its strength requirements, so as to avoid being too large or too small. The sum of long radius, short radius and clearance is equal to the center distance of the active and passive shafts.

Each rotation of the main shaft of Roots blower is equal to the air volume between the rotor and the casing for four times. Each time, the air volume is equivalent to the space part between the left rotor and the shell in Figure 1, and the section area of this space part is slightly equal to the 1 / 2 cross section of the rotor. Therefore, the air flow rate Q (m3 / s) of the fan should be:

Q = into vnnr ^ 2B

Where: n — speed, RPM / S;

R — long radius of rotor, m;

Rotor width, m;

The inlet v-volumetric efficiency is 0.7? 0.8, and the larger the air pressure difference between inlet and outlet is, the smaller the inlet V is.

From the above formula, it can be seen that the air flow rate is in constant direct proportion to the rotating speed. At the same time, the air output of the fan will also show the following characteristics:

(1) The air volume of the fan is the air volume under the state of inlet gas, not the standard state. The output is different because of the different negative pressure at the fan inlet.

(2) When the pressure of the fan is adjusted within the allowable range, the change of the air volume is very small and the range of pressure selection is very wide.

(3) How to improve volumetric efficiency must be considered in the operation of fan. Under the condition of ensuring the normal operation of the fan, the volume efficiency can be improved by minimizing the gap between the casing and the rotor and between the rotor and minimizing the air flow back to the inlet.

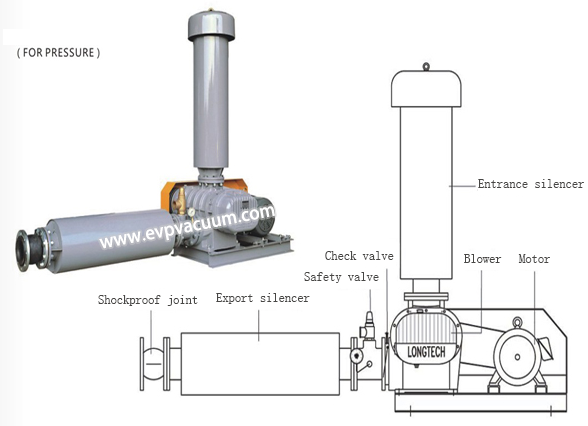

If the fan outlet encounters serious obstruction, the outlet air pressure will rise sharply, and there is the possibility of damaging the fan body. In order to protect the safety of Roots blower and equipment, especially to avoid damage to the seal of Roots blower, a safety valve is set at the outlet of the blower. When the pressure in Roots blower and equipment rises to a certain specified value (the opening pressure of the safety valve), the safety valve can automatically open and discharge the medium to prevent the pressure from continuing to rise. When the pressure in Roots blower and equipment is reduced to a certain specified value (the return pressure of the safety valve), the safety valve is automatically closed. At the same time, a one-way valve is set at the exhaust end of Roots blower, on the one hand, it can avoid the reverse rotation of rotor caused by the impact of gas backflow in the system during sudden shutdown and damage the fan; on the other hand, it can prevent the gas at the exhaust end of roots blower from returning to the parallel standby fan, resulting in loss of air volume and insufficient pressure.

The inlet and outlet of Roots blower are respectively installed with a large air resistance honeycomb muffler, and the resistance section adopts the form of multi chamber resistance rubber straight pipe channel and cross shaped sound absorption plate, so as to ensure enough noise reduction in a wide frequency range. Since the content of particles in the medium entering roots blower should not exceed 100mg / m3, the maximum size of particles should not exceed half of the minimum working clearance, that is, it should be below 0.1mm. Therefore, the filter must be connected before the muffler at the air inlet for purification.

In Roots blower, the gas is mainly adiabatic compression, but the compression ratio is not large, so the gas can be simplified as an incompressible fluid, and the required power is 0

N=QH/102η

Where: q is the air transmission volume, m3 / S;

H wind pressure, mmfto is kg / m2;

N efficiency, 0.7-0.8.

The static pressure at the inlet and outlet of the fan used in sulfuric acid production system is mainly determined by the sum of the resistance of the front and rear equipment.

The start-up and operation of Roots blower, the control method of standby machine switching, the treatment and precautions of abnormal state are related to its working principle and performance. When the fan is running, the driving power l of the prime mover to the fan is mainly consumed in two aspects: one is to make the air volume Q obtain the effective work l of the pressure head h; the other is the invalid work l consumed in the aspects of machine friction is invalid. When starting, the prime mover should also have the power l to make the stationary blower reach the rated speed. In this way, when the fan starts, the work to be done by the prime mover is as follows:

L = l valid + L invalid + l start

It is very important to master the required starting power correctly. To make a rigid body that can rotate from static state to rotational speed n, it is called moment of inertia, which is used to measure the inertia of the rotating body. Its value I = EMR2 is equal to the sum of the product of the mass of each particle of the rotating rigid body and the square of the vertical distance to the rotating axis.

When selecting fan motor, the power required for normal operation is mainly considered. It is impossible to add the total number of starting power. Otherwise, unnecessary waste may be caused by the light load of motor in normal operation. Otherwise, it will be impossible to start due to the high power required during startup.

In order to realize the load free, roots blower must understand the factors that affect the load. The load can be expressed by the product of the air transmission Q and head h. as long as any item is zero or reduced to a very small level, the conditions for the start-up without load (or basically no load) can be met. Centrifugal blower can close the inlet and outlet valve or one of the valves to achieve zero load, but the Roots fan can not adopt the measures of zero or substantially reducing the air flow due to its own structure, so only how to reduce the head H.

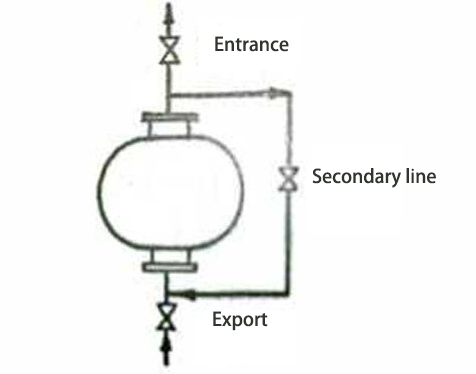

We connect a pair of lines at the fan inlet and outlet to make the gas at the fan outlet return to the inlet to reduce the head H. The connection method of auxiliary line is shown in Figure 3, before it is connected to the outlet valve after the inlet valve. The auxiliary line can not be started by any pipe. It is necessary to select the appropriate pipe diameter to make the rated air flow of the fan pass through the auxiliary line. At this time, the flow rate in the auxiliary line should be equal to or not more than 50m/s, so that the starting can not be problematic, and the low flow rate selection is not necessary to cause the diameter of the auxiliary line to be too large. When the flow rate reaches more than 80m/s and the motor is the standard configuration of fan, it is difficult to start. The value of 50m/s flow rate is derived from the calculation of the pressure difference between the inlet and outlet of the fan gas flowing through the auxiliary line, and the experience of daily collection of successful and failed start-up of blower with different auxiliary lines. The suitability can be verified when applied. It must be reminded that when the outlet valve is open and the fan is started, it must be ensured that it is not reversed by the gas from other blower. The sulfuric acid production system should not install vent valve in front of outlet valve.

In the operation of fan, the air volume is adjusted directly by using the small inlet valve or outlet valve, and the effect is very small, because it only changes the pressure difference between the inlet and the outlet, but the increment of the gas leaked back to the inlet from the gap is very small. Therefore, the air volume is adjusted in this way Without much value, it will significantly increase the power consumption of the fan, especially the reduction of the fan outlet valve has certain danger to the fan. Although the air volume is adjusted by small inlet valve, the negative pressure increases at the inlet, the status of the air at the inlet of the fan changes, which reduces the air volume in the standard state, which seems to be more effective than the regulating effect of the small outlet valve. However, the increase of power consumption is more serious from the calculation results, which is not acceptable.

Connecting a pair of lines after the inlet valve of Roots blower and the outlet valve is an important guarantee to ensure the safety of the fan body and sulfuric acid production system. Under the condition of system resistance in sulfuric acid production, if there is no auxiliary line, whether the inlet and outlet valves are open or closed, the fan start-up is difficult or dangerous, and some unexpected accidents may occur.

For sulfuric acid production system with full speed power frequency operation, only by adjusting the opening of the intake valve to adjust the air volume, so that the air inlet resistance increases and the air pressure decreases, which leads to the waste of electric energy; if the output exhaust air is used to adjust the output flow, the power consumption will also be caused.

Roots fan has the characteristics of constant torque load, and the system runs in constant torque and variable flow state after constant pressure control. The original power frequency control of Roots fan is transformed into frequency control, and the feedback closed-loop vector control is carried out by pressure sensor to realize frequency conversion and speed regulation. The system flow needs to be reduced by hours, and the speed of Roots fan is reduced, so that the Roots fan can operate at low flow point under specified pressure. The input power of Roots fan is approximately linear with the flow rate. Therefore, the operation speed and power consumption of Roots fan can be reduced after the frequency conversion transformation. The energy saving effect is mainly determined by the flow rate. The power consumption of Roots fan is proportional to the flow.

The frequency conversion control makes the operation system realize soft start and soft stop, which reduces the impact on the power grid when the system starts. The running speed of Roots fan reduces the mechanical wear, which extends the service life of motor and Roots fan.

When roots blower starts, wind speed control index of its auxiliary line must be verified in its own production system to confirm the best control value. In case of planned or emergency stop, it is important to remember to open the auxiliary line valve first before closing the inlet and outlet valves. In case of system blockage, it is necessary to judge whether the auxiliary line valve is opened immediately to solve the crisis.

It is very important to design the auxiliary line of Roots blower reasonably and get the correct operation and control in the starting, normal operation, standby machine switching and abnormal state by combining the scale and configuration of sulfuric acid production system.

The high efficiency of Roots blower not only brings convenience to workers, but also promotes the stable production of sulfuric acid.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)