hydrogen compressor of working principle and characteristics

Hydrogen compressor of introduction to the working principle and characteristics

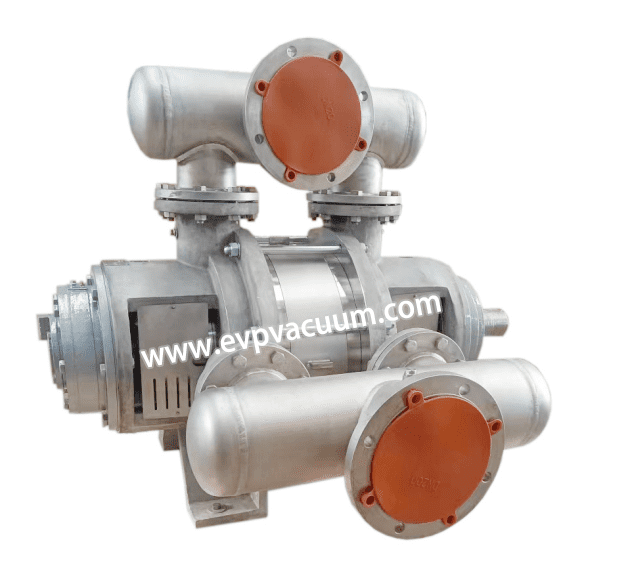

Hydrogen compressors can be selected from piston type, diaphragm type, centrifugal type, etc. The hydrogen compressor is an important equipment in the drying station, and its reliable operation must be ensured during the operation of the rectification device, which is a key focus of electrical maintenance work. Understanding the working principle of hydrogen compressors can help avoid erroneous judgments, quickly solve problems, and minimize unplanned equipment shutdowns when encountering problems during maintenance work.

The hydrogen compressor uses compressed air to achieve pressurized low-pressure hydrogen gas. The pressure of low-pressure air is converted into high-pressure hydrogen gas through a hydrogen compressor, and the pressure is infinitely adjustable. The pressure regulation of pressurized hydrogen can be achieved by adjusting the pressure of the driving gas source. It can compress low-pressure hydrogen gas and can be used for laboratory hydrogenation reactions. And the purpose of hydrogen cycling test.

Hydrogen compressors have the following characteristics:

(1) The working pressure range is large, and different types of pumps can be used to obtain different pressure zones. Adjusting the input air pressure and output air pressure can be adjusted accordingly. It can achieve extremely high pressure, with liquid pressure of 300Mpa and gas pressure of 90Mpa.

(2) Wide flow range, all models of pumps can operate smoothly with only 1kg air pressure, achieving the minimum flow rate. By adjusting the intake volume, different flow rates can be obtained.

(3) Easy to control, from simple manual control to fully automatic control, all meet the requirements.

(4) Automatic restart, regardless of the reason for the pressure drop in the holding circuit, will automatically restart to supplement the leakage pressure and maintain a constant circuit pressure.

(5) Safe operation, gas driven, no arc or spark, suitable for use in hazardous environments.

(6) Energy saving can reach 70%, as maintaining pressure does not consume any energy.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)