Hydrogen Compressors in Green Hydrogen Field of Application

What is Green Hydrogen?

Hydrogen energy is clean, low-carbon, has high calorific value, diverse sources, and flexible storage and transportation, and is expected to become the “ultimate energy” of the 21st century. Unlike other fuels, hydrogen can be produced using fossil fuels or renewable energy sources. Its combustion only produces water and does not produce substances that pollute the environment. Moreover, the heat generated by combustion is high, and sustainable hydrogen utilization can be achieved through energy carriers and circular carbon economy.

According to the sources of hydrogen production and the carbon emissions during the production process, hydrogen can be divided into grey hydrogen, blue hydrogen, and green hydrogen. Gray hydrogen refers to the hydrogen gas produced through the combustion of fossil fuels. Blue hydrogen refers to the hydrogen gas produced by adding CCUS (Carbon Capture, Utilization, and Storage) carbon capture, utilization, and storage technology during the hydrogen production process. Green hydrogen is hydrogen produced from renewable energy sources such as wind, hydro, solar, and nuclear power, with no carbon emissions during the hydrogen production process. At present, hydrogen energy is mainly produced through grey hydrogen, and the proportion of green hydrogen is expected to increase rapidly. At present, grey hydrogen accounts for about 95% of global hydrogen production, and it emits a significant amount of carbon dioxide during its preparation process. Green hydrogen has completely zero emissions during the preparation process and can be coupled with renewable energy. Its proportion is expected to continue to increase in the future, gradually replacing gray hydrogen.

Green hydrogen industry chain

The green hydrogen industry chain is divided into upstream hydrogen production, midstream hydrogen storage and transportation, and downstream application. For the upstream hydrogen production process, the electrolytic cell is the core device, and the cost of hydrogen production by electrolyzing water is still relatively high. However, considering the future collection of carbon taxes and the continuous reduction of green hydrogen costs, the cost gap between green hydrogen and grey hydrogen is expected to gradually converge. With the development of the hydrogen energy industry chain, hydrogen storage and transportation such as hydrogen storage bottles, hydrogen compressors, hydrogen valves, downstream hydrogen fuel cell enterprises, hydrogen bicycles and other fields are all facing significant development opportunities, which are worthy of long-term attention.

Application of Hydrogen Compressors in Green Hydrogen Field

There are various types of compressors used in the field of hydrogen energy, including hydrogen production feed gas compressors, hydrogen filling compressors, and hydrogen refueling station compressors, depending on their applications.

The application of hydrogen compressors in the field of green hydrogen mainly refers to hydrogen filling compressors. Hydrogen filling compressors are mainly used in the process of filling hydrogen into tank trucks in hydrogen production plants, and are one of the compressor products with a large shipment volume. The working principle of hydrogen filling compressors is similar to that of hydrogen refueling station compressors. From a technical perspective, there are also three different types: diaphragm compressors, liquid driven compressors, and ion compressors. At present, among the three technological routes, diaphragm compressors are widely used in the domestic hydrogen filling process and occupy a dominant market position.

The outbreak of the green hydrogen industry will become a new growth point driving the demand for hydrogen filling compressors. The Chinese Academy of Engineering predicts that by 2050, China’s hydrogen consumption will reach over 100 million tons, with the increase mainly coming from renewable energy electrolysis of water for hydrogen production. “Green hydrogen” is widely used in transportation, chemical raw materials, industrial energy, and construction fields, accounting for about 10% of China’s terminal energy structure, and the annual output value of the industrial chain is about 12 trillion yuan. In the future, green hydrogen projects are expected to become a blue ocean market for compressors.

With the expansion of industry application demand, domestic compressor companies have begun to iterate new hydrogen filling compressor products, mainly in the direction of increasing displacement.

In this situation, the world’s first “liquid driven+diaphragm” technology solution has been adopted to develop a new series of liquid driven diaphragm hydrogen filling compressors for special working conditions such as “frequent start stop, cold start, and load start stop”.

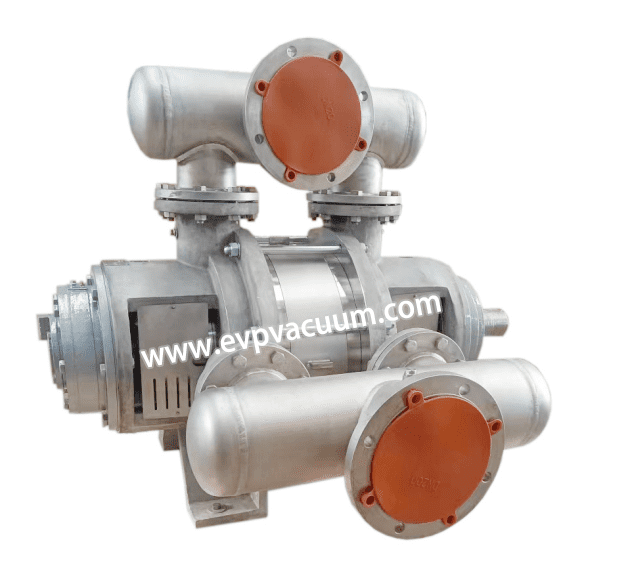

The liquid driven diaphragm hydrogen filling compressor for hydrogen energy, specifically: the gas compression part adopts a mature diaphragm structure, and the driving part adopts a “hydraulic pump driven, rotary reversing valve reversing” scheme, using a hydraulic pump to drive hydraulic oil instead of the traditional piston and crank connecting rod driven hydraulic oil. We have innovatively added a self-developed pressure reducing cylinder component between the hydraulic directional valve and the diaphragm assembly, which can adapt to different exhaust pressure and displacement requirements by adjusting the pressure reduction ratio without adjusting the main structure. The whole machine still continues the modular design, with a more flexible layout and more convenient disassembly, assembly, and maintenance.

The hydrogen energy hydrogen filling compressor adopts a two-stage, dual membrane head compression scheme. The key components of the whole machine, such as plunger pump, air valve, diaphragm, pressure reducing cylinder, reversing valve, overflow valve, etc., are independently designed and developed, and the core technology of the whole machine and key components is mastered. The compressor body is separated into a pry for easy transportation, installation, and maintenance of the equipment.

Focusing on the research and development, design, production, and sales of hydrogen compressors for hydrogen preparation, storage, transportation, refueling, and recovery processes.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)