Jet condensing vacuum system

1, an overview of the

In the chemical industry, pharmaceutical industry, oil, sugar, salt, food, dairy products, wastewater treatment and other industries, atmospheric evaporation concentration, crystallization, dehydration, decolorization and other processes of high energy consumption, the consumption of heat sources is very much, and the above operations in the vacuum state not only reduce energy consumption, but also greatly improve the production efficiency, so vacuum evaporation concentration, vacuum crystallization, vacuum dehydration, vacuum decolorization and other processes have been widely used.

2. Comparison of advantages and disadvantages of several vacuum systems

At present, the following vacuum systems are widely used in vacuum evaporation, vacuum crystallization, vacuum dewatering and vacuum decolorization in industrial production.

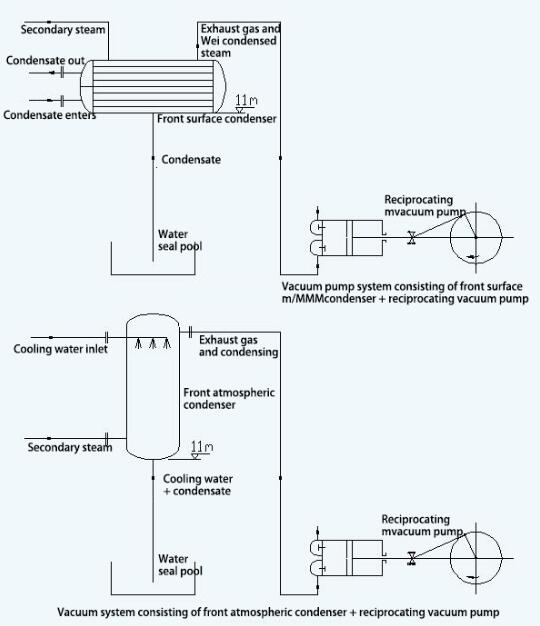

(1) Vacuum system composed of precondenser +W reciprocating vacuum pump

Advantages: high vacuum, low evaporation temperature, suitable for evaporation of low boiling point and heat sensitive materials;

Disadvantages: after the steam from the pre-condensing condenser enters the vacuum pump, the emulsification of the lubricating oil loses its lubrication effect, leading to the extremely short service life of the vacuum pump, high failure rate of the equipment, frequent maintenance affects the normal production, the vacuum pump oil must be changed frequently, the maintenance cost is high, the vacuum pump must be opened and prepared.

Process flow chart:

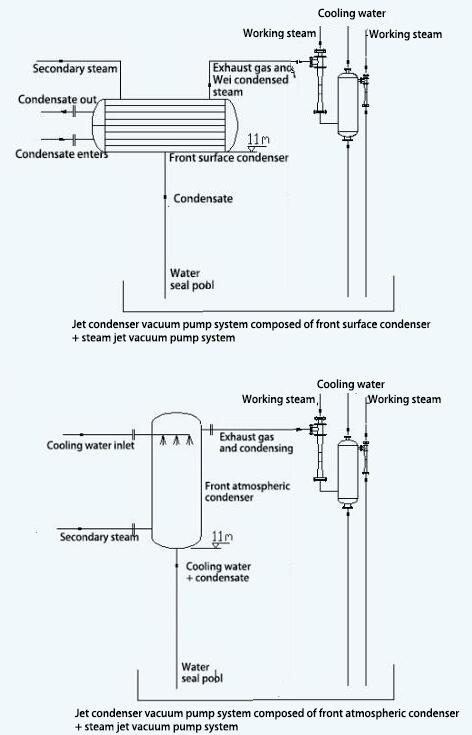

(2) Jet condensing vacuum system composed of pre-condenser and steam jet vacuum pump

Advantages: high vacuum, low evaporation temperature, suitable for evaporation of low boiling point and heat sensitive materials; Long service life, corrosion resistant materials can be used to manufacture, equipment failure rate is low, can be continuous production without maintenance.

Disadvantages: Must have certain pressure steam as working power.

Process flow chart:

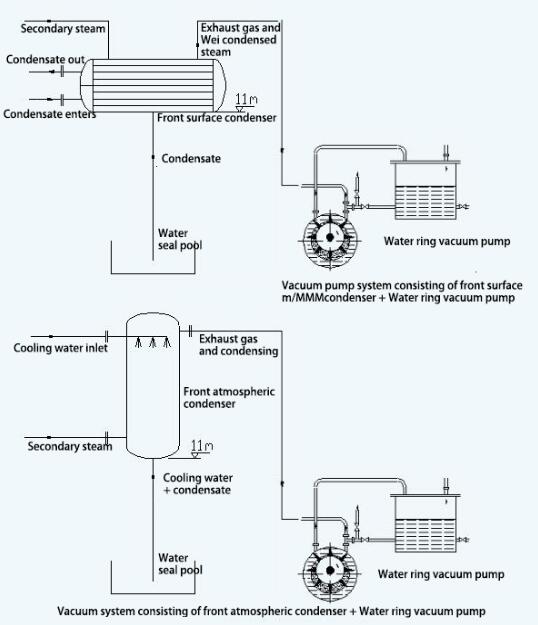

(3) Vacuum system composed of precondenser and water ring vacuum pump

Advantage: A small amount of steam can be absorbed from the pre-condenser.

Disadvantages: low vacuum, not suitable for evaporation of low boiling point and heat sensitive materials; Vacuum pump service life is short, eccentric impeller easy wear, vacuum pump must be opened and prepared.

Process flow chart:

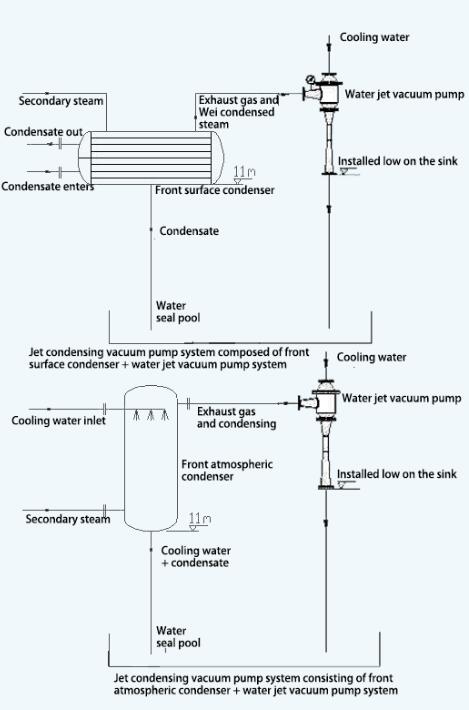

(4) Jet condensing vacuum system composed of pre-condenser and water jet vacuum pump

Advantages: compared with water ring vacuum pump, high vacuum degree, low evaporation temperature, suitable for evaporation of low boiling point and heat sensitive materials; Long service life, corrosion resistant materials can be used to manufacture, equipment failure rate is low, can be continuous production without maintenance.

Disadvantages: the vacuum of the steam jet pump is lower than that of the non-condensable gas.

Process flow chart:

3. Process parameters provided by users are required

(1) Physical properties of materials;

(2) Evaporation temperature of materials;

(3) Required vacuum degree (absolute pressure or working pressure of the system);

(4) Secondary steam evaporation;

(5) Temperature of cooling circulating water;

(6) Cooling circulating water pressure;

(7) Whether there is a steam source or steam pressure;

(8) Other relevant parameters;

4. Design the process route according to the user’s process parameters

After the process parameters are determined, the technical department of our company will determine the water injection and condensation vacuum system or steam injection and condensation vacuum system according to the customer’s conditions, and provide selection and quotation services.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)