Liquid ring compressor used in Biogas Production

Biogas production and consumption are increasing in a world concerned with both the cost of energy and the environmental impact of energy production and waste disposal. Biogas production facilities, like digesters, landfills and waste water treatment plants require robust equipment to handle the wet, acidic gas produced.

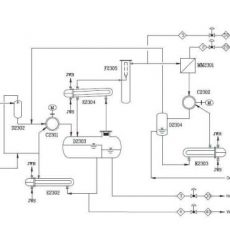

The biomass produced in activated sludge tanks and clarifying tanks is stabilized in the digestion tower and used to produce biogas. Thorough mixing of the sludge increases the gas yield and reduces its retention time in the reactor. In the process, the gas is withdrawn from the upper part of the digestion tower, compressed in the liquid ring compressor.

Liquid ring compressor Application:

Organic Waste Digester

One type of organic waste is manure. Manure digester gas is one of the fastest growing sources for RNG and a tough gas to handle. As bacteria breaks down the organic matter in the lagoon, the methane that is produced typically contains high levels of H2S, CO2 and heavily saturated with H2O, these conditions are easily handled by EVP Liquid ring compressor.

Landfill Gas

Waste-to-energy profitability at a landfill may depend upon the efficiency and reliability of the compression technology selected. For years EVP compressors have been utilized in LFG applications providing low maintenance, 24/7 operation and remarkable turndown capabilities.

Waste Water Treatment Plants

Vital to our society and our everyday way of life. EVP compressors are collecting gases in waste water treatment plants all over the world. These plants are processing billions of gallons of sewage. In many cases the plants are using the sewage gases to run engine-generators, creating electricity to utilize in their facility.

Pros and Cons of Using a Liquid Ring Compressor as a Gas Compressor

Pros

1.Ability to handle carryover resulting in minimal process problems and an increase in uptime; intended for severe applications

2.The long design life offering the highest reliability

3.No internal lubrication required, which means less maintenance and downtime

4.No metal-to-metal contact and constant wear-free performance

5.Cool running, minimal temperature rise between inlet and discharge that is ideal for explosive gases and vapor recovery applications

6.Only one moving part for simple and reliable operation

7.Simple and compact structure

8.Relatively steady flow of gas without pulsation

9.Low operating temperatures

10.Low vibration

11.Most importantly, when using a liquid compressor, the gas compression is isothermal, making it possible to pump flammable and explosive gas. Also, with no friction surface or exhaust valve, pumping gas with dust or a mixture of vapours and non-condensable gas becomes possible.

12.Discharged gas can be 100% oil free

Cons

1.Efficiency is often lower than dry type or oil lubricated machines

2.Water is required for service liquid or cooling.

As you can see, a liquid ring compressor has far more advantages than disadvantages. Although this rotating positive displacement device has some similarities to a rotary vane compressor, there are also distinct differences. Primarily, the liquid ring compressor utilizes a centrifugal rotor instead of sliding vanes. Rotary slide vane machines require lubricants such as oil therefore discharged gas is oil contaminated. Water consumption can also be recovered or recycled with liquid ring compressors.

Edited by: Annie Hou; Copyright: EVP Vacuum Pump

Related products: liquid ring compressor/liquid ring vacuum system/package

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)