Vacuum pump used in wood treatment- Impregnation

In today’s increasingly tight timber resources, how to effectively use the timber produced by artificial fast-growing forests to achieve a wider range of applications is an effective measure to relieve the tension of timber resources and an effective means to protect natural forests.

Wood is an indispensable material in human life. It is pure and light, has high strength, and is easy to process. However, wood also has defects such as easy deformation, perishable, flammable, etc. Therefore, it is very important to carry out necessary protective treatment before use. Necessary, including flame retardant, smoke suppression, anti-corrosion, anti-mildew, anti-decomposition, anti-termite, dyeing, etc. The above-mentioned processing equipment for wood usually adopts processing equipment such as vacuum and compression.

The wood preservative vacuum pressure impregnation treatment tank is the key equipment for wood preservative and flame retardant; the wood in the tank is treated by chemical impregnation, pressure infiltration, vacuum drying and other processes, which can effectively prevent the mold caused by wood rot fungi and other bacteria. Corrosion; can effectively prevent the destruction of wood by insects such as termites, wood borers and other animals. Adding different medicaments has the effect of flame retardant and coloring at the same time. Greatly improve the service life and application range of wood. Anticorrosive wood and flame retardant wood are widely used in indoor furniture materials, antique garden buildings, railways, mines, wharf guards, pile wood ship construction and other occasions.

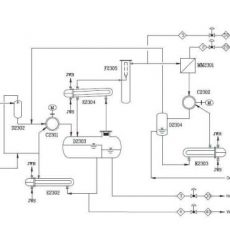

Load the wood into a vacuum pressurized tank → close the tank door → vacuum (about -0.98Mpa) → inject medicament → boost and maintain pressure (1.0-1.4Mpa) → decompression → drain → post vacuum (about -0.98Mpa) → Emptying → Out of the tank

The operation process can be divided into 5 stages:

1.Pre-vacuum stage:

Put the wood into the pressure impregnation tank, close the door of the tank, turn on the vacuum pump, draw a vacuum to the impregnation tank (generally -0.080~-0.095MPa), keep it for 15 minutes to extract the air in the wood cell cavity, so that Wood is easy to be impregnated by preservatives, and the preservatives are reduced when pressure is relieved, and more preservatives are retained in the wood.

2.Add preservative stage:

Add the preservative solution without turning off the vacuum pump, that is, maintaining the original vacuum. If the vacuum pump is turned off before the preservative fills up the pressure impregnation tank, the remaining air in the impregnation tank or the vapor generated by the treatment solution will be compressed to the upper part of the impregnation tank, then when the preservative solution is continued to be added These gases will fill the space evacuated in the upper part of the wood pile during the vacuuming process, so that this part of the wood will absorb a smaller amount of preservative solution, resulting in uneven up and down of the wood processed in the same batch.

3.Pressurization stage:

When the preservative is filled with the pressure impregnation tank, turn off the vacuum pump and eliminate the vacuum, apply pressure (either hydraulic or air pressure) to reach the required pressure (usually 0.8 ~ 1.5 MPa) for a period of time (generally 2-6 hours), until the required preservative dose has been deeply pressed into the wood, or to the point where the wood refuses to absorb the preservative solution. When the pressurization phase is over and the pressure is removed, due to the expansion of a small amount of air compressed in the wood, 5-15% of the preservative solution absorbed by the wood during the pressurization phase will recoil from the wood at this time. Into the pressure immersion tank.

4.Drainage stage:

After the pressure is relieved, the gravitational action of the preservative solution or a drain pump is used to return the preservative solution in the pressure infusion tank to the preservative solution storage tank.

5.Post-vacuum stage:

After exhausting the preservative solution, close all valves, turn on the vacuum pump, and start the post-vacuum phase. The vacuum degree of the back vacuum can be the same as that of the front vacuum (-0.080~-0.095MPa), or a little lower, and keep it for 10-30 minutes. Then the vacuum is released, and the preservative solution drawn in the post-vacuum stage is released. Open the tank door and take out the treated wood. The preservative treatment has been completed.

6.Take off the wood, simply clean the surface of the wood and enter the drying stage

Copyright: EVP Vacuum Pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)