Liquid ring vacuum pumps are used for sea water desalination

The survival and development of all creatures on land are inseparable from fresh water. However, the shortage of fresh water is an important problem affecting human survival and social development. Ocean-going ships, military warships, Marine resource surveys, and the survival of humans and creatures on isolated islands are all dependent on fresh water. It is not easy to carry and transport fresh water from the land, sometimes it is impossible, and the sea water is rich in resources, convenient materials, direct desalination of sea water in the local water use, both economic and practical. Especially at present, China is developing naval navigation, ocean-going investigation and other undertakings, which need a lot of fresh water. Therefore, seawater desalination has become a hot research and application direction and needs to move from scientific research to large-scale production.

With the development of shipping industry, ships have an increasing demand for fresh water. Especially for large warships such as aircraft carriers operating at sea for a long time, it is almost impossible to carry a large amount of fresh water from the land, and it is also unrealistic to rely on islands to supplement fresh water. Therefore, the application of seawater desalination treatment technology is very necessary.

At present, the main methods for obtaining fresh water from seawater or brackish water are: electrodialysis, evaporation, multi-effect distillation, vacuum distillation, reverse osmosis, membrane distillation, etc. Membrane distillation is a new membrane separation technology. Drived by the pressure difference across membranes, the volatile components in the solution are vaporized on the membrane surface and transferred through the hydrophobic porous membrane. The membrane distillation process can be divided into direct contact type (DC-MD), air gap type (AGMG), gas purge type (SGMD) and vacuum type (VMD) according to the different condensing mode or expelling mode of steam at the condensing side. Vacuum membrane distillation (VMD) technology is expected to be widely used in seawater desalination, brackish water desalination, aqueous solution treatment, solution concentration and environmental protection due to its unique advantages. The research directions of seawater desalination mainly include theory, process method and equipment. The key problem to be solved is to improve production efficiency and reduce production cost. Improving freshwater production and simplifying production equipment; Improve the quality of fresh water, simplify the production process.

Vacuum distillation seawater desalination of principle

Vacuum distillation technology for seawater treatment, referred to as VDT

Vacuum distillation desalination device generally adopts the principle of vacuum distillation, that is, through the vacuum pump that can pump water vapor, to maintain 90%~94% of the vacuum degree in the device, at this time the corresponding boiling point of seawater evaporation is only 46℃~36℃, in order to use low temperature waste heat for seawater distillation and desalination. For example, the heat source of seawater desalination can be used in the cooling water of the ship’s main engine cylinder liner, which belongs to waste heat recycling. A ship driven by a diesel engine with the main engine power of about 6000KW can produce 15~18m3 of fresh water every day. It’s very efficient.Ship waste heat such as: waste heat boiler generated by excess steam, auxiliary cylinder liner water have a lot of waste heat, so ship waste heat has a very broad prospect of development. Vacuum distillation does not need additional heat sources for desalination, so VDT technology is an important means of Marine desalination, with the advantages of energy saving and high efficiency.

Vacuum distillation seawater desalination of basic process

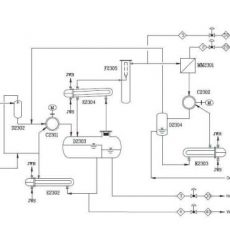

The vacuum distillation unit used for seawater desalination mainly consists of preheater, evaporator, condenser, water ring vacuum pump and fresh water tank.

The sea after a preheater in which absorb water and the heat released by the steam water ring vacuum pump work, the temperature rise, for the seawater desalination device of the condensed in the condenser water evaporation (secondary steam), the resulting steam temperature further increases, part for into the evaporator of seawater desalination device as water supply, another part of the cabin outside eduction; The seawater supplied to the evaporator is heated by the working steam (primary steam) in the evaporator, and the temperature rises to reach the saturation temperature and begins to evaporate. The steam obtained rises in the device, and the fresh water separated by the separator. After the heat is transmitted to the seawater by the preheater, it enters the fresh water box for storage. The unevaporated seawater in the desalination plant becomes concentrated and discharged out of the ship.

So how is “vacuum” as the core keyword of vacuum drying achieved?

Here, a vacuum pump is needed to achieve vacuum. The vacuum pump provided by Shanghai EVP Vacuum Technology Co., Ltd. can meet the needs of different models/different sizes of vacuum distillation machine, Common vacuum pumps is:

1.2BE liquid ring vacuum pump, the ultimate vacuum is 33hpa, and the gas volume is 246m3/h-9450m3/h.

2.2BE3 liquid ring vacuum pump, the ultimate vacuum is 33hpa, and the gas volume is 4200m3/h-62400m3/h

3.CL cone structure liquid ring vacuum pump, the ultimate vacuum are 80hpa-440hpa, and the gas volume is 1320m3/h-4980m3/h

If you have any questions, please feel free to contact us and look forward to your consultation.

Copyright: EVP Vacuum Solutions