Vacuum pumps are used for membrane separation

Membrane separation is a new separation technology which appeared at the beginning of 20th century and rose rapidly after 1960s.Membrane separation technology with both the function of the separation, enrichment, purification and refining, and high efficiency, energy saving, environmental protection, molecular filtration and filtration characteristics such as simple process, easy to control, therefore, at present has been widely used in food, medicine, biology, environmental protection, chemical, metallurgical, energy, oil, water treatment, electron, bionics, and other fields, has a huge economic and social benefits,It has become one of the most important means of separation in modern science.

Membrane separation technology refers to a technology that achieves selective separation of a mixture of molecules of different particle sizes at the molecular level when passing through a semi-permeable membrane. It is used in drinking water purification, industrial water treatment, food and beverage water purification, sterilization, and biologically active substances. Recycling, refining and other aspects have been widely used, and quickly spread to various fields such as textiles, chemicals, electricity, food, metallurgy, petroleum, machinery, biology, pharmacy, and fermentation. Due to its unique structure and performance, separation membranes have emerged in environmental protection and water resource regeneration. They have broad application prospects in environmental engineering, especially wastewater treatment and reclaimed water reuse.

Because of the superior performance of membrane separation technology, the membrane process is regarded as a very important new technology in the 21st century industrial technology transformation.Experts have pointed out that: who master the membrane technology who will master the chemical industry tomorrow!

Membrane is a material with selective separation function. The process of using membrane selective separation to realize the separation, purification and concentration of different components of materials is called membrane separation.

The difference between membrane separation and traditional filtration is that the membrane can be separated in the molecular range, and this process is a physical process.

Shanghai EVP Vacuum Technology Co.,Ltd has a good application in membrane separation process. We can provide important vacuum & compression products with membrane separation units to meet customers’ process requirements. The following is the product inquiry we have received from our customers:

Brief Process Description:

The membrane separation unit is a recovery unit for the nitrogen recycle stream of the Powder Treatment Vessel. The feed stream contains nitrogen, hexane and small amounts of ethane, ethylene, butene, water vapor and Hydrochloric acid.

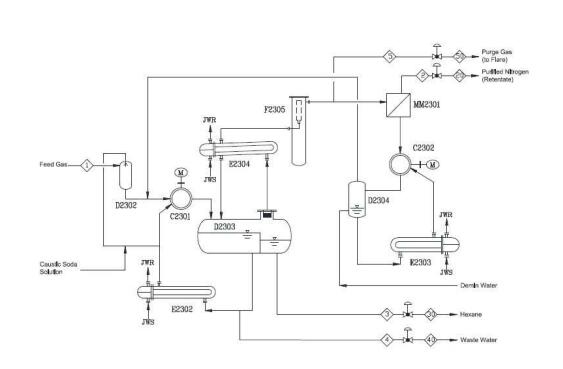

The process flow diagram of the Membrane Separation Package Unit is shown as follows:

The membrane separation unit consists of neutralization, compression, condensation, membrane separation and vacuum. The membrane separation unit operation is adaptable to process conditions fluctuation such as feed flowrate or compositions, which ensures that the unit can provide the similar performance.

This application requires a compressor to compress the feed to about 6.0 bar. Based on the supplied parameters and medium, we recommend the LRC series liquid ring compressor.

Capacity: 1200m3/h

Suction pressure: 1.02barA

Discharge pressure: 7barA

Mechanical seal: Cartridge Dual Mechanical Seal

LRC series liquid ring compressor, the ultimate vacuum is 0.7MPa(G), and the gas volume is 900m3/h-2400m3/h.

In the following use link, the participation of liquid ring pump is needed to enrich normal hexane and water vapor, and the medium is returned to the suction side of the compressor through the liquid ring pump vacuum pump. According to the provided parameters and medium, we recommend our 2BE1 series liquid ring vacuum pump to the customer:

Capacity: 1600m3/h

Suction pressure: 0.18barA

Discharge pressure: 1.02barA

Mechanical seal: Cartridge Dual Mechanical Seal

2BE liquid ring vacuum pump, the ultimate vacuum is 33hpa, and the gas volume is 246m3/h-9450m3/h.

In addition to vacuum pumps and compressors, EVP contracts the complete unit, including the technical confirmation, review, design, scheme out, details integration and later installation, commissioning, etc.

If you want to learn more, please call EVP.

Copyright: EVP Vacuum Solutions

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)