Liquid ring compressor used in solar power plants

Solar power generation is an important direction of new energy utilization. The main form has trough type, tower type, dish type three systems. The biggest advantage of solar power generation is that the power output is stable, can do basic power, can do peak regulation; In addition, its mature and reliable energy storage (heat storage) configuration allows continuous power generation during the night.

Solar power generation refers to the use of large-scale array of parabolic or disc mirrors to collect solar energy, through the heat exchange device to provide steam, combined with the traditional turbine-generator process, so as to achieve the purpose of power generation. Using solar power generation technology, avoid expensive silicon crystal photoelectric conversion process, can greatly reduce the cost of solar power generation. Moreover, this form of solar energy has an advantage that other forms of solar conversion cannot match. The water heated by the sun can be stored in huge containers, which can still run steam turbines for hours after the sun goes down.

In the solar thermal plants, the Heat Transfer Fluids(HTF) are used as the energy transfer medium. But at high temperatures, the mixture of aromatic compounds currently used for heat transfer fluids gradually forms hydrogen (H2), which reduces the efficiency of the solar thermal system.

Therefore, the H2 concentration in the HTF must therefore be kept below an acceptable value. To overcome this problem, technicians who develops a concept to remove the hydrogen from the HTF.

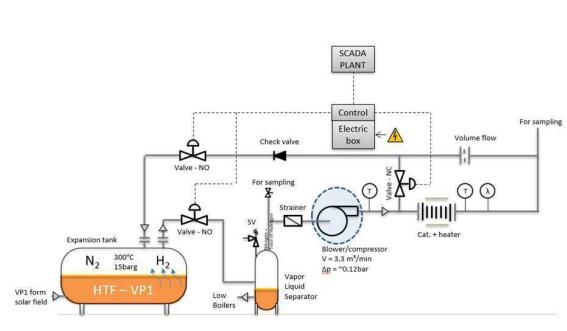

The schematic representation the scheme is shown as below:

The heat transfer fluid is in contact with the blanketing nitrogen in the Expansion tank at 300°C and 15barg as shown below.

From the expansion tank the nitrogen and trace of hydrogen is transferred to the Catalyst using a blower/compressor. Once the hydrogen is removed from the catalyst, the nitrogen is sent back to the expansion tank.

Therefore, only need a blower/compressor to transport the gas mixture through the catalyst with maximum pressure drop of the system is (max) 0.15 bar. The approximate volume flow rate of the gas mixture is 200 m³/hr.

Based on technical, the technical requirement of the blower/compressor as follows:

Operational temperature: 300°C

Static pressure: 15 bar

ΔP = 0.15 bar

Volume flow 3.3 m³/ minute

Connection details: DN 100 pipe

Flow speed = 7 m/s

Fluid – Nitrogen + Trace of Hydrogen

Overall pressure drop over loop: ~0.15 bar

According to the above parameters, we recommend LRC liquid ring compressor in series.

LRC liquid ring compressor, the Max. Pressure is 0.7Mpa (G), and the pumping speed is 900m3/h-2400m3/h.

We can also supply other compressors with different pressures and pumping speed, such as SY&2SY (double stage) series liquid ring compressors.

SY liquid ring compressor, working pressure range 0.15-0.3Mpa (G), pumping speed 90m3/h-1800m3/h

SY liquid ring compressor, working pressure range 0.3-0.6Mpa (G), pumping speed 90m3/h-2100m3/h

According to the needs of customers, Shanghai EVP provides complete product units to meet customers’ higher pressure requirements. Please feel free to contact us if you have any relevant questions.

Copyright: EVP Vacuum Solutions

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)