Liquid ring vacuum pump and compressor in Poly Butadiene II in petrochemical industry

PROCESS SPECIFICATION

During maintenace programs, for oxygene purging, one vacuum unit is considered to evacuate air (oxygene) from drums & pressure vessels which supposed to be in service.

By this system nitrogen consumption will be minimized and oxygene removal will be expedite. So, liquid ring compressor with surge drum & seperator are implemented.

There is a vacuum header which connected to compressor in one side and to the drums & vessel from another side.

The liquid ring compressor shall be desing as total recirculation to minimized water usage.

EVP have cases in Poly Butadiene II production:

In the pilot plant, which needs two closed-circle water ring compressors and one closed-cycle water ring vacuum pump system.

The following part the nominal operation parameters of the thermochemical plant:

Process parameter requirements for 1st water ring compressor units:

Process medium: polybutadiene

Inlet pressure: 1.01bar(a)

Exhaust pressure: 3.5bar(a)

Limit exhaust pressure at outlet: 4bar(a)

Inlet air volume: 966m3/h

Inlet temperature: 40 ℃

Maximum capacity of a single compressor: 1200m3/h

Material requirements: all wetted parts are made of stainless steel 304

Sealing method: double-end machine sealing with Plan 53A flushing system

Explosion-proof requirements: Ex Dii BT4

EVP model: SY-20 liquid ring compressor

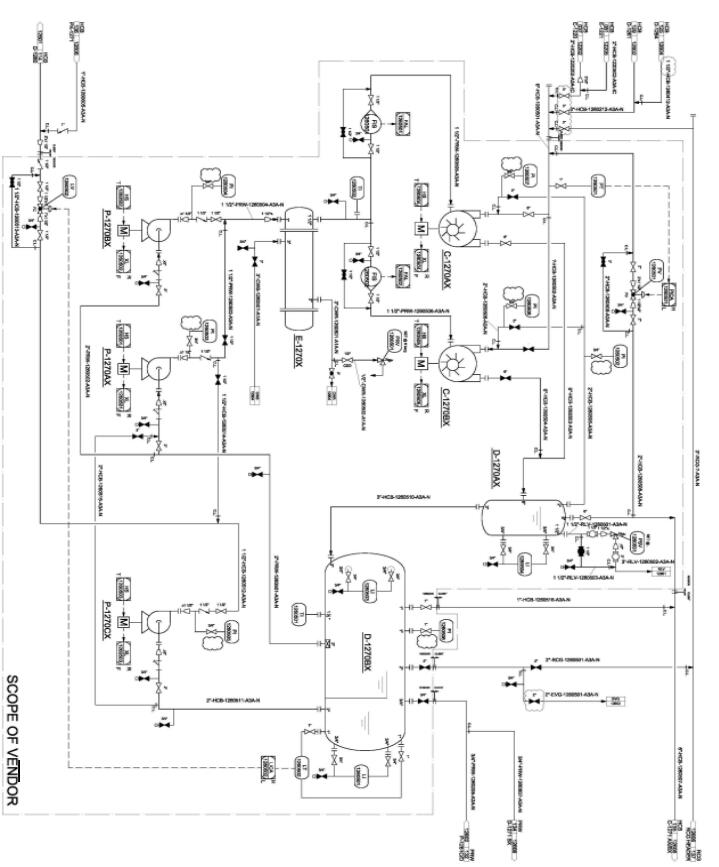

Process flow chart (for reference only)

Process parameter requirements for 2nd water ring compressor unit:

Process medium: polybutadiene

Inlet pressure: 3.21bar(a)

Exhaust pressure: 5.7bar(a)

Inlet air volume: 189m3/h

Inlet temperature: 40~65 ℃

Maximum capacity of a single compressor: 360m3/h

Material requirements: all wetted parts are made of stainless steel 304

Sealing method: double-end machine sealing with Plan 53A flushing system

Explosion-proof requirements: Ex Dii BT4

EVP model; SY-6 liquid ring compressor

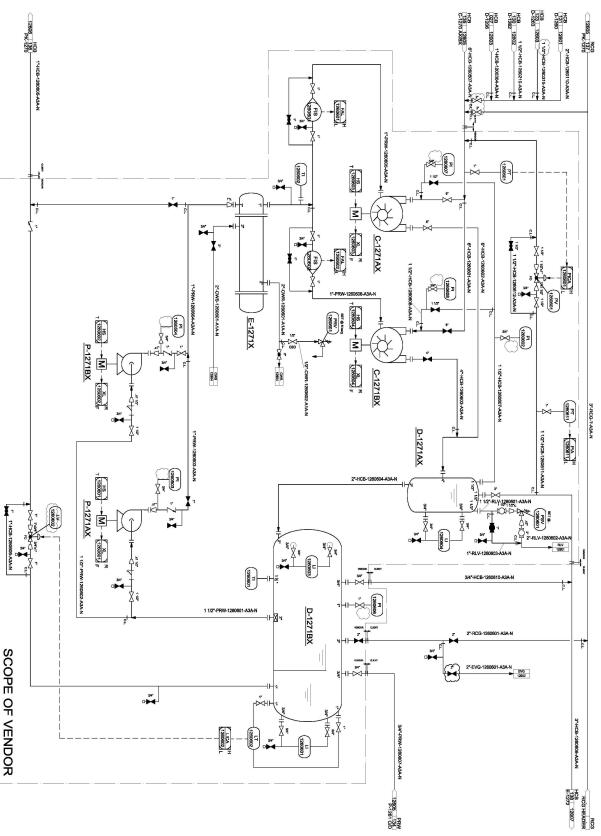

Process flow chart (for reference only)

Process parameter requirements of 3rd water ring vacuum pump unit:

Process medium: air

Exhaust pressure: 1atm

Inlet air volume: 1080m3/h

Ultimate pressure: 33mbar.abs

Working fluid flow rate: 2.6m3/hr

Material requirements: all wetted parts are made of stainless steel 316

Sealing method: single end face mechanical seal

Explosion-proof requirements: Ex Dii BT4

EVP model: 2BE1-203 liquid ring vacuum pump

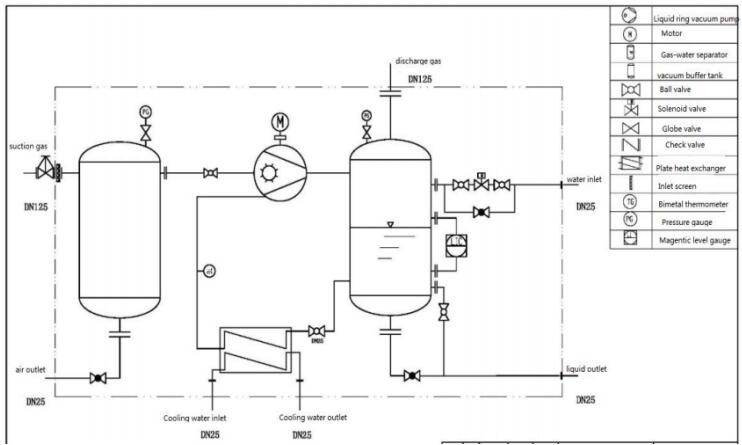

Process flow chart (for reference only)

Below is our provided liquid ring compressor systems and liquid ring vacuum pump system

Edited by: Shanghai EVP Vacuum Technology Co., ltd

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)