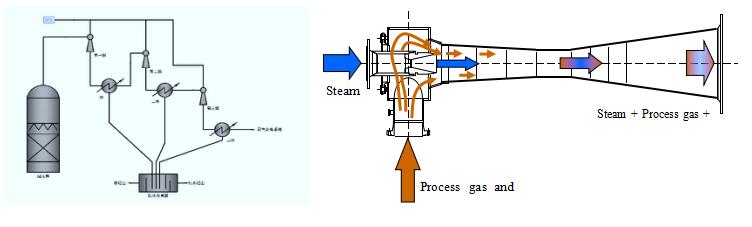

Steam ejector system used in petrochemical industry

Solutions :

1.Vacuum System of full Steam ejector

Operating principle:

A.Can be simply understood as the steam flow mixed with the pumped air stream

The mutual conversion of pressure and kinetic energy.

B.Usually use the mass Flow to select the model(Kg/h)

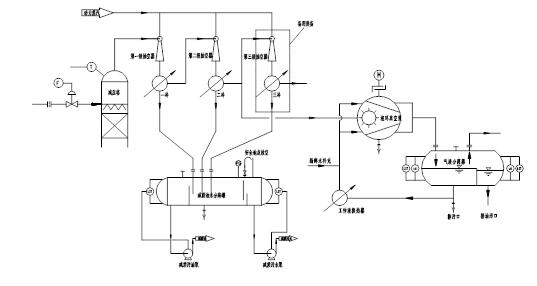

2.Vacuum System of Steam ejector +watering pump

System Features:

use of a steam injection + liquid ring pump vacuum system has the following advantages:

A.High working vacuum, stable operation and simple maintenance

B.The energy-saving effect is obvious, especially suitable for large-scale oil refining devices, and the energy-saving and consumption-reducing effect is more obvious. Compared with the full steam-jet vacuum system, the annual operating cost can be saved by more than 30%, which has a good application prospect.

3.Vacuum System of Dry mechanical pump

Operating principle:

A.Through the continuous rotation of the rotor, the pumped gas is sucked from the air inlet into the space v0 between the rotor and the pump casing, and then discharged through the exhaust port. When the top of the rotor turns over the edge of the exhaust port, when the v0 space communicates with the exhaust side, the gas pressure on the exhaust side is higher,Then a part of the gas is returned to the space v0, so that the gas pressure suddenly increases. When the rotor continues to rotate, the gas is exhausted Outside the pump.

B.Usually use the Volume Flow to select the model(m3/h)

How To Select A Steam Ejector System:

1.The pressure of the steam.

2.The temperature of the steam.

3.Air inlet vacuum.

4.Outlet pressure.

5.What is the medium.

Keywords: Steam Ejector System ; liquid Steam Ejector System; Vacuum System of Dry mechanical pump

Edited by: Annie Hou / Shanghai EVP Vacuum Technology Co., Ltd.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)