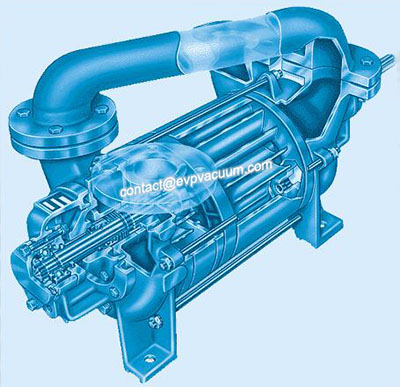

Liquid ring vacuum pump disassembly procedure

All parts of the liquid ring vacuum pump shall be cleaned thoroughly during maintenance. The specific steps of disassembly and assembly are as follows:

1、 Remove the vacuum pump cover and diaphragm

1. Unscrew and remove the screw (063a), and remove the diaphragm of liquid ring vacuum pump cover and O-ring (058a) assembly along the axial direction

2. In general, it is not necessary to remove the diaphragm from the vacuum pump cover, but if necessary

(1) Replace the diaphragm (2) clean, replace the valve plate or remove the diaphragm from the vacuum pump cover when the O-ring of the cavitation protection pipe (3) falls off

3. When the diaphragm (0488) is removed from the vacuum pump cover (061a), a Φ 12M, l = 140mm round rod can be inserted into the drain port of the liquid ring vacuum pump cover to push it out. After the diaphragm is removed, the valve plate baffle (051a), valve plate (050a) and cavitation protection pipe (071a) can be removed from the disk

2、 Remove impeller and mechanical seal

1. Unscrew the bolt (063a), remove the vacuum pump cover (061a), diaphragm (048b) and O-ring (058a)

2. Screw out the screws (125A), (044a), take out the impeller pressing plate (127a) and adjusting washer (153a), pull out the impeller (047a) through the pulling tool, and remove the flat key (006a) from the main shaft.

Remove the mechanical seal (035a). In order to remove the mechanical seal more easily, the motor shaft before the mechanical seal can be coated with water for lubrication (oil or grease is prohibited for rubber bellows seal).

If there are calcifications such as scale on the electric shaft, the mechanical seal shall be removed after it is cleaned up, otherwise it is easy to damage the mechanical seal

3、 Remove the vacuum pump body

1. First, remove the impeller according to the previous instructions, but it is not necessary to remove the static ring part of the mechanical seal, because when the liquid ring vacuum pump body is removed, the static ring part of the mechanical seal will be pushed out.

2. Remove the bolts and tap gently along the axial direction to remove the vacuum pump body (002a) from the main shaft.

3. If the vacuum pump body or mechanical seal needs to be replaced, remove the mechanical seal flange from the vacuum pump body, and then take out the static ring part of the mechanical seal.

4、 Install the vacuum pump body

1. Install the static ring part of the mechanical seal onto the mechanical seal flange, install the set screw, place the O-ring (131A) into the groove of the mechanical seal flange, and then connect it to the vacuum pump body with bolts.

2. When installing the static ring part of mechanical seal (035a), wet it with water and press it into the mechanical seal flange evenly by hand. Pay attention not to use too much force! After assembly, check whether the seal flange and vacuum pump body are assembled tightly

3. Bolt the vacuum pump body (002a) to bracket 133a. Take care not to damage the static ring part of the mechanical seal.

5、 Install mechanical seal

1. Thorough cleaning is very important. The smooth surface of mechanical seal and the damage of elastic seal must be avoided. The assembly surface of elastic seal shall be smooth without damage

2. When installing the moving ring part of the mechanical seal (035a), the sleeve can be used to press it to a proper position on the shaft (the spring compression is about 4mm), and then tighten the set screw.

6、 Install impeller

1. Apply lubricating oil evenly on the shaft

2. Press the impeller (047a) onto the shaft, and ensure that a clearance of 0.30 ± 0.05mm is reserved between the impeller (047a) and the front end face of the vacuum pump body (002a).

If the clearance is too small, it may cause mechanical failure: if the clearance is too large, it will cause the decrease of the pumping rate of the vacuum pump

3. Put in the adjusting washer (153a), and fasten the impeller pressing plate (127a) to the impeller with screws (125A), (044a)

7、 Installing vacuum pump cover and bulkhead

1. Place the motor end of the bracket down and vertically on the ground.

2. Place the prepared diaphragm (048b) on the vacuum pump body (002a), and make sure that the 4.3mm-diameter hole on the vacuum pump body (002a) close to the diaphragm (048b) is accurately combined with the locating pin (037a).

3. Place the O-ring (058a) on the diaphragm (048b) without twisting, then push it to the bottom of the diaphragm to make the O-ring contact with the vacuum pump body (002a).

4. Apply sealant evenly and continuously to the sealing surface on the side of vacuum pump cover (061a) from the top of diaphragm (048b). Hz-1312 oil resistant silicone sealant can be used. After applying the sealant, install the vacuum pump cover (061a) onto the vacuum pump body (022a) and diaphragm (048b), and tighten it with bolts (063a).

When installing the vacuum pump cover, pay attention to that both ends of the cavitation protection pipe (071a) must be installed in the corresponding holes of the diaphragm and the pump cover respectively.

5. Install the vacuum pump cover (061a) and diaphragm (048b) as a whole.

6. The vacuum pump cover and diaphragm are integrated. Put the vacuum pump cover on the vacuum pump body and fasten the vacuum pump cover on the vacuum pump body with bolts.

7. After the vacuum pump is installed, turn the motor fan by hand, and the vacuum pump must rotate smoothly. If the vacuum pump rotation is not smooth or there is friction sound during the vacuum pump rotation, the vacuum pump cover shall be removed, the impeller clearance shall be checked and readjusted

8. If you need to order spare parts, you should provide part name, spare part number, model and factory number of liquid ring vacuum pump to Xin’anjiang industrial vacuum pump.