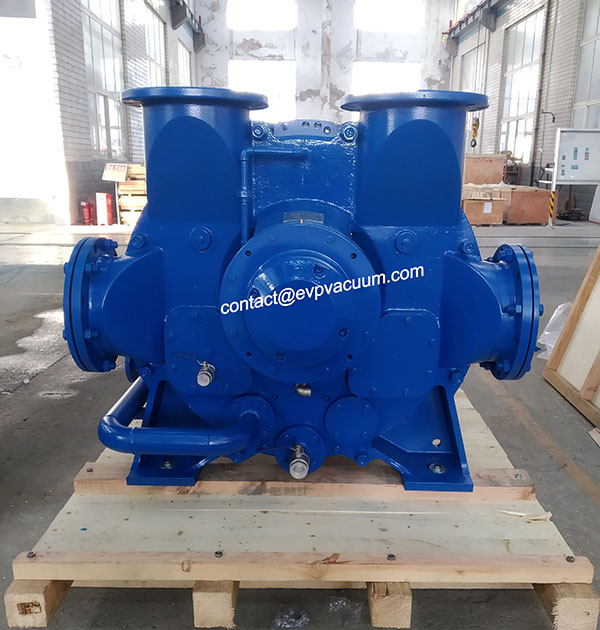

Liquid ring vacuum pump equipment

Sometimes when we use the liquid ring vacuum pump, we will find that its working efficiency is very low, and the comparison of working efficiency in normal use in peace time is very obvious. Then what factors affect the efficiency of the equipment? Let’s have a look.

1. Steam pressure

When the steam pressure is low or fluctuates, it will have a greater impact on the production efficiency of the equipment. Therefore, it is necessary to ensure that the steam pressure is higher than the required working pressure. However, because the structure design of the equipment used has been finalized, if the steam pressure is increased too much, the air extraction and vacuum degree will not be increased. In addition, it is also necessary to ensure that the steam pressure supplied by the boiler is in a stable state. It is recommended to use a special boiler to provide working steam for the steam jet pump, so that the steam pressure will not fluctuate and the performance of the liquid ring vacuum pump will be stable.

2. Nozzle

Nozzle is the main reason that affects its efficiency, and there may be some problems: wrong and crooked nozzle installation, liquid ring vacuum pump, blockage, damage, corrosion and leakage.

However, no matter what kind of preventive measures are used, nozzle blockage is inevitable. On the one hand, when installing the steam pipe, the residual iron filings and welding slag in the pipe will cause the nozzle to be blocked; on the other hand, when the system is out of service, the steam pipe is easy to rust, so the rust spots will fall and block the nozzle when it is in use.

If the output of the liquid ring vacuum pump is low, it will affect the suction capacity of the equipment. In this case, there is a problem on the parts of the equipment, which needs to be solved in time. Otherwise, it will cause problems in other aspects of the equipment. Next, we will work with Xiaobian to connect the cause of low output and take what measures to solve the problem.

1. Sealing effect of shaft end

The equipment can achieve the purpose of sealing through the packing at the shaft end, so as to ensure its suction capacity. If the number of packing at the shaft end is small or the sealing force of packing is insufficient. It will cause air leakage at the shaft end, which will affect the suction capacity of the equipment and reduce its output.

2. Sealing effect of valve plate

The flexible exhaust holes at both ends of the equipment are respectively provided with separate valves, whose main function is to avoid the condition that the internal compression of the cavity is not up to the standard, so as to ensure the working efficiency of the whole equipment. The state design of the valve is as follows. The lower end of the valve fits the section disc of the liquid ring vacuum pump without gap, but the upper end shows a “s” shape. Because of this design, the stress is accumulated for a long time. It is easy to cause damage and crack of valve plate. In general, if one side of the valve plate is broken, the temperature of the intake pipe will suddenly drop, and the pump equipment will move violently. If the valve pieces on both sides are broken at the same time, the vacuum will drop sharply and the energy consumption will increase dramatically.

Liquid ring vacuum pump is mainly used for suction. In many cases, it needs to be used for a long time, and cannot be stopped during operation, otherwise it will affect the whole process, but this may also cause the equipment to burn out the motor due to overload. Let’s see how to avoid this situation.

Liquid ring vacuum pump uses hydraulic coupling, which can make the pump work under high pressure difference, so as to avoid overload of the equipment.

Hydraulic coupling is usually installed between pump and motor. Under normal working condition, the hydraulic coupling transmits rated torque to the pump through the motor end. The pressure difference of liquid ring vacuum pump is determined by the torque transmitted by the hydraulic coupling, and the torque transmitted by the hydraulic coupling is adjusted by its liquid volume. When the pump starts to run at the same time of high-pressure difference and front stage pump, there will be speed difference in the liquid coupling, that is, sliding, which only transmits a part of torque, so that the pump is in the state of deceleration. With the process of air extraction, the gas load decreases, and the equipment will gradually accelerate to the rated speed.