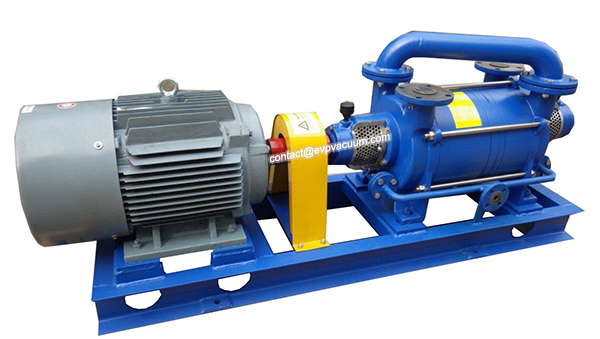

Liquid Ring Vacuum Pump for Brick Making Production Line

In the 1990s, China’s vacuum technology level has made great progress, especially in the late 1990s, the vacuum industry in the reference of foreign advanced experience. With the continuous efforts of technicians, the domestic vacuum technology level has been greatly improved.

At the first wall and roof material production equipment exhibition held in Chongqing in 1998, since the vacuum pump manufacturers advocated the use of liquid ring vacuum pump in brick and tile machinery, the liquid ring vacuum pump has been gradually recognized and used by many manufacturers, and has gradually replaced the reciprocating vacuum pump and water jet vacuum pump, becoming the mainstream configuration of vacuum brick machine vacuum system. Liquid ring vacuum pump is a vacuum pump to obtain coarse vacuum. Its limit pressure is – 0.098mpa for two-stage pump and – 0.099mpa for series atmospheric ejector.

2SK two-stage liquid ring vacuum pump absorbs the advantages of liquid ring vacuum pump at home and abroad reasonably in structure, and is manufactured by careful design on the basis of original SK pump. This type of vacuum pump cancels all paper pads and structural adjustment pads, and completely interchanges all parts, greatly facilitating assembly and maintenance. The vacuum pump has the advantages of high vacuum degree, high pumping speed in high vacuum degree area, low energy consumption, reasonable and compact structure, safe and reliable use, convenient installation and disassembly, etc.

This type of vacuum pump cancels all paper pads and structural adjustment pads, and completely interchanges all parts, greatly facilitating assembly and maintenance. The vacuum pump has the advantages of high vacuum degree, high pumping speed in high vacuum degree area, low energy consumption, reasonable and compact structure, safe and reliable use, convenient installation and disassembly, etc.

Liquid ring vacuum pump in brick production line main types

Liquid ring vacuum pump is widely used to pump various gases and corrosive gases without solid particles. Today, we will introduce the classification of liquid ring vacuum pump according to its action mode:

(1) Single action

The impeller and the vacuum pump body are single eccentric, and the impeller rotates for one cycle to conduct one-time suction and exhaust. The liquid ring vacuum pump has the advantages of simple structure, easy manufacture, large suction and exhaust window area, long compression section, and high efficiency and limit vacuum.

At the same time, because the internal wall of the vacuum pump is cylindrical, smooth and without mutation, the liquid ring is not easy to produce eddy current and cavitation during operation, especially suitable for corrosive occasions of the liquid ring.

(2) Double action

The impeller and the vacuum pump body of the double acting liquid ring vacuum pump are in double eccentricity, and the suction and exhaust are carried out twice for each rotation of the impeller.

The double action can be divided into radial, axial suction and exhaust. The structure of this method is more complex and the manufacturing requirements are stricter. The joint of the base circle and two eccentric circles of the liquid ring vacuum pump body is a mutation point. When the liquid ring moves along the wall, there is a vortex near this point, which not only causes a large local loss and low efficiency, but also causes the cavitation caused by the vortex. When the liquid ring is corrosive, it is easy to produce a combination of cavitation, corrosion and flushing. The vacuum pump body and impeller are damaged quickly.

At the same time, because of the short compression section, the limit vacuum is low and the air volume in the high vacuum area is small, but the radial force of the rotor can be automatically balanced.

Compared with the single acting type, when the same impeller peripheral speed, speed, length and hub ratio are ignored, the same energy provided by the impeller to the liquid ring is only used to compress half of the gas, that is, the compression capacity of the liquid ring used for unit air volume is twice as large, which is suitable for the liquid ring energy In the case of large demand for quantity, the air volume curve drops smoothly within the working pressure range when the compressor is designed.

In the actual operation, if the liquid ring vacuum pump with the same performance requirements is designed to be double acting and single acting respectively for comparison, no matter the volume or weight of the vacuum pump, the two are the same, even the single acting will be smaller than the double acting.