Liquid Ring Vacuum Pump for Evaporator

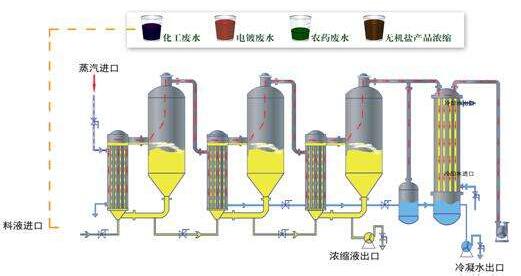

Vacuum evaporators are widely used in the evaporation and concentration of water or mailing solvent solutions in the pharmaceutical, food, chemical, light industry and other. It is especially suitable for heat sensitive materials (such as important production water, alcohol extract, antibiotic fermentation broth, milk, juice, etc). Continuous concentration at low temperature under vacuum conditions is necessary to ensure product quality.

The important parameters relates to vacuum evaporation are heating temperature, heating surface dimension, vacuum degree, and depth of material layer. The heating temperature is generally limited by the characteristics of the material. Which cannot to be too high. Especially for the evaporation for heat sensitive material, which has more limitation. In this condition, the vacuum degree and heat diffusion surface should be increased greatly to enhance the evaporation volume and distillation efficiency. The increased vacuum degree can lower the boiling point of solvent. For example, the vacuum should be less than 10mmHg for heat sensitive material.

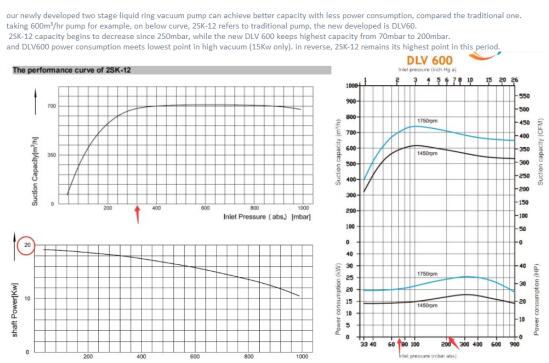

EVP newly developed two stage liquid ring vacuum pump’s efficiency is greatly improved. It remains highest working capacity from 50mbar to 300mbar as shown on below curve.

It’s your ideal option to ensure well product quality. Contact us freely for more detail.

Tags: Liquid ring vacuum pump ,DLV two stage liquid ring vacuum pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)