Difference between liquid ring vacuum pump and compressor

The liquid ring vacuum pump and liquid ring compressor share same working principle, but their basic form and structure differs. The difference can be difined as following five aspects:

1. different circumferential velocity range of its mpeller

The impeller circumferential velocity is mainly determined by the pressure difference between suction chamber and compression chamber. Since the compressor’s suction pressure is atmospheric pressure, while the exhaust pressure of vacuum pump is atmospheric pressure. The pressure difference on compressor is larger, herewith the required circumferential velocity is large.

Compressor 18 ≦ μ2 ≦ 24

Vacuum pump 14 ≦ μ2 ≦ 17

The range of optimal impeller circumferential velocity varies:

Compressor μ2 , optimum = 23-24 m / s

Vacuum pump μ2, optimum = 16 m / s

Herewith, the equipment has different performance when working as vacuum pump or as compressor. Only should rotation speed be enhanced when a vacuum pump is worked as compressor. So that it can work economically.

2. different optimal compression ratio range

The optimal compression ratio is the compression ratio at higer point. In general, the vacuum pump’s optimal compression ratio is higher than the compressor’s.

3. different shaft power

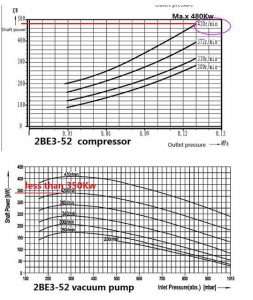

The liquid ring vacuum pump in same size/model, its shaft power is less than that when working as compressor. Since the impeller circumferential velocity is designed as per request of vacuum pump, the machine is kept working on low efficiency, its shaft power is larger. Therefore, the compressor’s rated motor power should be larger than vacuum pump’s.

For example: EVP model 2BE3-52, rotation speed at 420rpm. When worked as vacuum pump, its max. Shaft power is only 331Kw, while it’s 455Kw when worked as compressor (remark: the shaft power refers to equipment’s power consumption). Below curve is good example:

4.different structure for suction & discharge manifold

Vacuum pump more often uses square/box type (refer photo 1) manifold, its overflow pipeline is just water tube. While the compressor uses tubular manifold (refer photo 2). Its overflow pipeline is regulated by fload valve, in order to prevent the water on compressor chamber being discharged with gas when below overflow level. It is used to decrease the gas pressure and effevtive gas volume.

remark: “photo 1″vacuum pump with square type suction & discharge manifold

“photo 2” compressor with tubular type suction & discharge manifold

5. Size of exhaust hole different

For same size/model equipment, the compressor has smaller discharge port than vacuum pump.

On economical consideration, users prefer to use same equipment as compressor and vacuum pump for different production process. Whether it is used as compresor or vacuum pump, it uses same motor with same rotation speed, and same discharge port. The difference is considered only when its motor power, suction & discharge manifold is selected.

EVP have sufficient experience on liquid ring vacuum pump and compressor, followed are photo from working site for your kindly reference.

We are pleased to provide professional solution if you have such request.

Tags: liquid ring vacuum pump ,water ring compressor

Editor: Shell Hu (EVP Vacuum Solution)

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)