Negative Pressure System

Negative Pressure System / Medical Central Pressure Station

the negative pressure system or medical central station (followed name as station) usually is assembled by single stage rotary vane vacuum pump, or liquid ring vacuum pump.

The pump start or stop automatically at set pressure on equipped gauge, whole set controlled by electric control box.

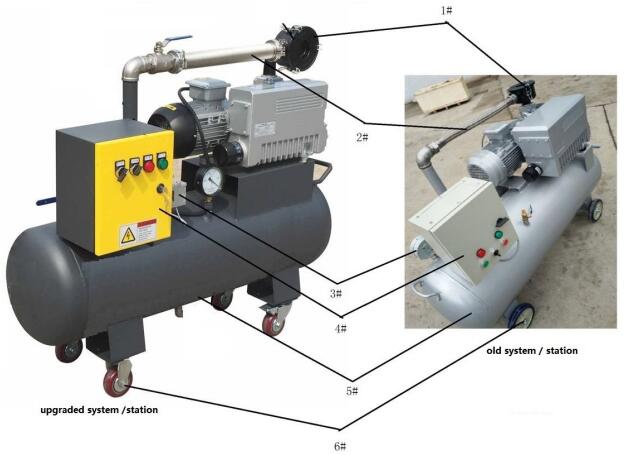

Through efforts , upgrade CVS central vacuum system was done on the station as following:

| No. | item name | old | upgrade | advantage |

| 1# | air inlet filter | mounted vertically | mounted horizontally | easy access to filter core in maintenance and prevent dust in filter core fall into pump chamber in replacing filter core |

| 2# | connecting tubes | braided bellows | stainless steel bellows | better appearance, with reinforced aging resistance |

| 3# | pressure gauge & mechanical switch | mechanical controlled | SMC digital display & pressure switch | pump started or stopt automatically in more accurate vacuum; easier to read vacuum degree, |

| 4# | electric control box | standard | control box wall thickened | increased stability |

| 5# | negative pressure tank | 150L | standardized to industrial stand 125L | universal size makes equipment more convenient to replace existing one; less installation space. |

| 6# | wheel | 4 directional wheels | 2 directional wheels+2 omni-directional wheels | better direction control while moving the station. |

Notes: same upgrades also suits for station combined by liquid ring vacuum pump.

Tags : rotary vane vacuum pump、Liquid ring vacuum pump 、CVS central vacuum system ()

Edited by : Shell Hu

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)