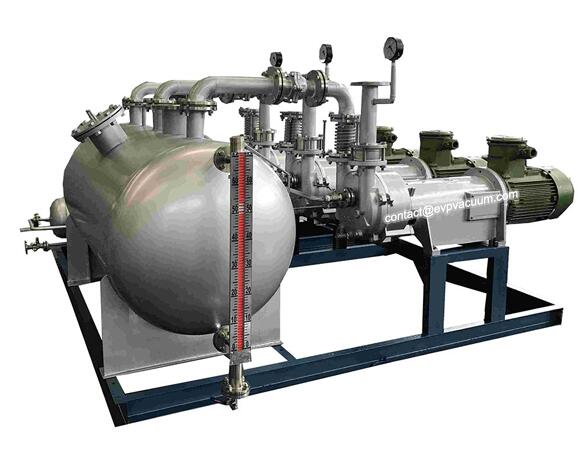

Liquid ring vacuum pump unit

Liquid ring vacuum pump unit of working principle

The pumped gas enters the liquid ring vacuum pump from the suction port. After being compressed by the liquid ring vacuum pump, it enters the gas-liquid separator together with part of the working fluid. In the gas-liquid separation device, the gas-liquid phase is separated.

Liquid ring pump will generate heat in the process of operation, the main heat includes: the vacuum pump’s invalid power, the suction gas temperature higher heat, the suction gas contains condensable gas in the process of compression release phase change heat.

The main function of heat exchanger is to cool the working fluid by cooling water to keep the temperature of the working fluid within a reasonable range.

Liquid ring vacuum pump equipment composition:

Main components of closed-circuit circulation system of liquid ring vacuum pump include:

◆ ring vacuum pump

◆ gas-liquid separator

◆ heat exchanger in pieces

◆ common base

◆ internal pipeline

Four reasons to choose the EVP vacuum

01.EVP vacuum relies on advanced production technology and perfect testing equipment to become the leader in the vacuum industry

EVP vacuum mainly from the water ring vacuum pump, water ring vacuum unit, screw vacuum pump, roots vacuum pump, reciprocating vacuum pump, vane vacuum pump and vacuum complete equipment research and development, production and sales as well as vacuum engineering services. Relying on technological innovation and market development, EVP vacuum has gradually developed into a first-class vacuum equipment supplier in China.

02. For the sake of the use of the unit, carefully manufacturing, purchasing raw materials storage test more stringent

High quality and high stability products are derived from EVP vacuum’s constant pursuit of perfection in details. Therefore, we strictly control every product from design, production, test and delivery, and carry out layer upon layer inspection in every link from raw material purchase to product delivery, so as to ensure the product quality and performance in every field stable operation.

03. Ultra-high cost performance saving 15%-30% year on year

There are complete production equipment and testing equipment, to ensure that every product has passed the strict test and qualified before being handed over to the customer. We attach great importance to the “commonality” and “interchangeability” of product parts in product design. And every product has a complete technical file, to ensure that the user’s products can be timely and fast maintenance

04.360 degree service system, so that you have no worries

Rapid response commitment: 4 hours to make the processing plan, 8 hours to implement the person, 24 hours to arrive at the site. The worry-free service system ensures that customers can get a quick response to on-site problems in the shortest time, effectively shortening the communication period, and solving customers’ urgent needs. To provide customers with thorough and perfect all-round pre-sale, sale, after-sales technical services. The company’s products for life responsibility system, always provide technical support and technical services.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)