liquid ring vacuum pump uses

Liquid ring vacuum pump in chlor-Alkali industry of application

Chlor-alkali industry

The chlor-alkali industry is the industry that produces chlorine (Cl2) and alkali, sodium hydroxide (NaOH) or potassium hydroxide (KOH), by electrolysis of a salt solution. The main technologies applied for chlor-alkali production are mercury, diaphragm and membrane cell electrolysis, mainly using sodium chloride (NaCl) as feed or to a lesser extent using potassium chloride (KCl) for the production of potassium hydroxide.

Chlorine production since the 1940s has risen enormously, on the back of the burgeoning demand for plastics, notably PVC and polyurethanes. The production of chloroaromatics (e.g. chlorobenzene for phenol synthesis), propylene oxide (chlorohydrin process), solvents containing chlorinated hydrocarbons, and inorganic chlorine compounds are also important factors behind the increased use of chlorine after 1940. The chlorine production of a country is an indicator of the state of development of its chemical industry.

Chlorine is largely used in the synthesis of chlorinated organic compounds. VCM for the synthesis of PVC still remains the driver of chlor-alkali production in most European countries. Sodium hydroxide is usually supplied as a 50% aqueous solution and can be stored for long periods and readily transported (rail, road and ship). The main areas of application of sodium hydroxide today are:

– chemicals: synthesis of organic or inorganic compounds

– metallurgy, alumina/aluminium industry

– pulp and paper industry

– textile industry

– soaps, surfactants

– water treatment

– consumer products.

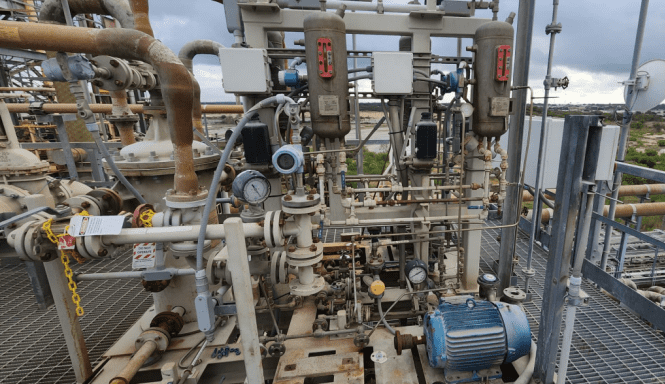

Liquid ring vacuum pumps in the Chlor-Alkali industry uses

Chlor-alkali products are of many types and highly correlated. Its downstream products reach thousands of varieties and have high economic extension value. It is widely used in important industries such as agriculture, petrochemicals, light industry, textiles, building materials, electricity, metallurgy, national defense and military industry.

These uses make liquid ring vacuum pumps an ideal choice in the chlor-alkali industry. Especially when high efficiency, stability, and low maintenance costs are required, liquid ring vacuum pumps can provide reliable solutions.

Material selection in the Chlor-Alkali industry

The chlor-Alkali industry is a highly corrosive industry. The process media and products in its production process, such as saturated brine, wet chlorine, caustic soda, hydrochloric acid and sulfuric acid, are all extremely corrosive. Therefore, the structural materials of the equipment must be carefully selected in the chlor-alkali production project, otherwise leakage will occur in production, seriously affecting the normal production and product quality.

The titanium pumps used in the membrane method or mercury electrolysis method for chlorine production can achieve the highest economic benefits. The titanium pumps of the American company Pifick have a service life of up to 10 years. Beijing Chemical Plant No. 2 used cast titanium 6BA-12 pumps in the vacuum dechlorination process, Dg100 and Dg150 stop valves, and titanium impellers of HTB-7011 liquid ring ceramic vacuum pumps. After working for 1.5 years, they are still intact and show no signs of corrosion.

The EVP team once met a customer from the Chlor-Alkali industry in North America who used a SIHI liquid ring vacuum pump closed unit to remove free chlorine. Because the pump was broken, the system could not be used. Based on the customer’s specific working conditions, the EVP team recommended titanium 2BV6-111, which not only could replace the customer’s old pump well, but also saved the customer’s cost.

For more information about the chlor-alkali industry and the selection of compressor vacuum pumps, please consult Shanghai EVP Vacuum Technology Co., Ltd.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)