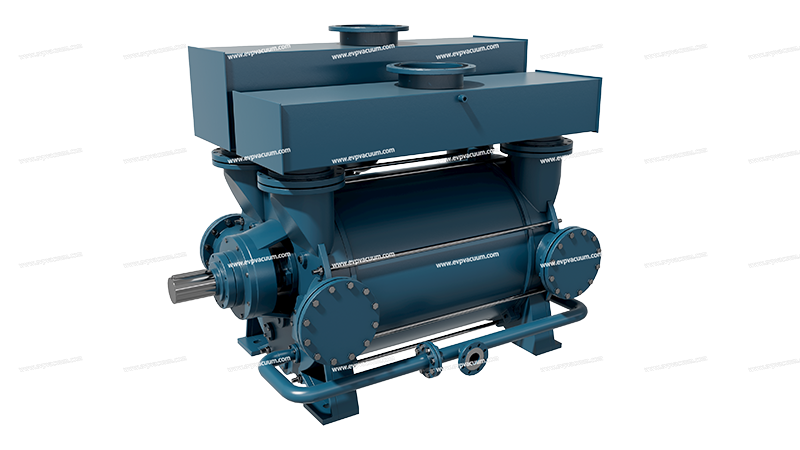

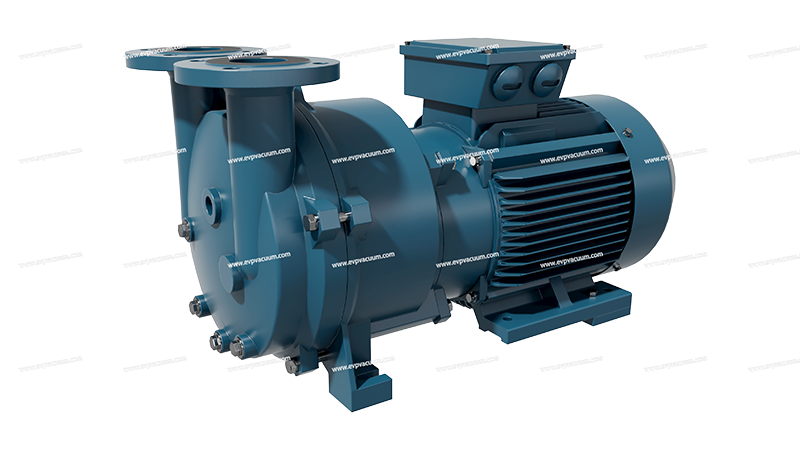

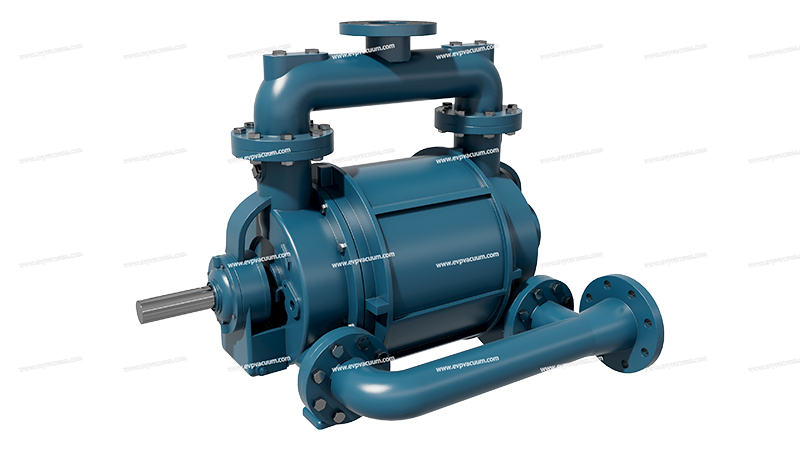

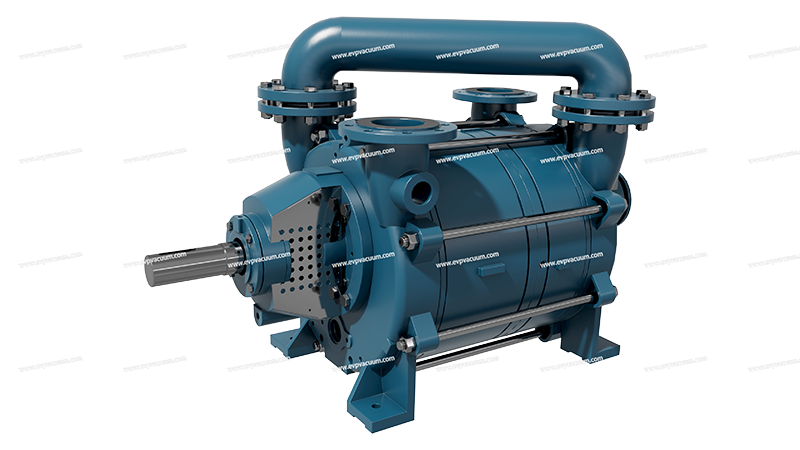

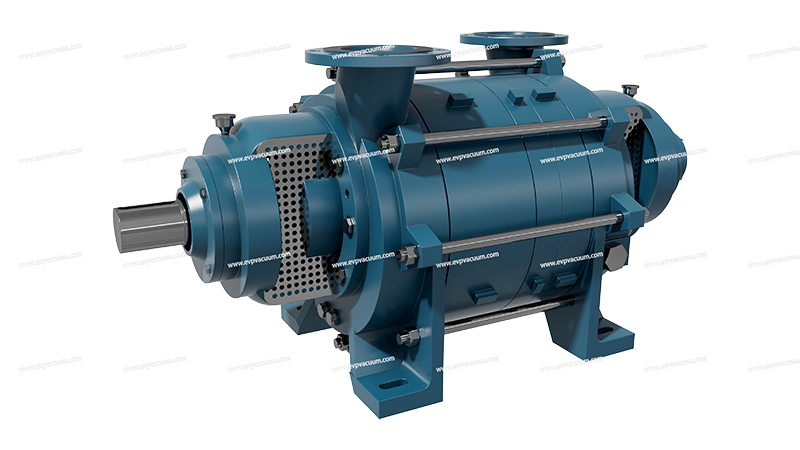

Liquid/Water Ring Vacuum Pumps

Liquid Ring Vacuum Pumps (LRVPs) & Water Ring Vacuum Pumps (WRVPs)

Liquid ring vacuum pumps (LRVPs) are rotary displacement pumps that use a rotating impeller inside a cylindrical casing partially filled with a sealing liquid (typically water). The centrifugal force created by the impeller forms a liquid ring, which acts as a seal and compresses the gas to generate vacuum pressure.

How They Work:

Impeller Rotation: The eccentrically mounted impeller spins, creating centrifugal force that forms a liquid ring.

Gas Intake: Gas enters through the inlet port as the impeller creates expanding chambers.

Compression & Discharge: The liquid ring compresses the gas, which is then expelled through the discharge port.

Key Features:

Sealing Liquid: Water is most common (hence “water ring vacuum pump”), but other liquids (oil, solvents) can be used for special applications.

Non-contacting Design: Minimal wear since the impeller doesn’t touch the casing.

Handles Wet & Dirty Gases: Tolerant of vapors, particulates, and condensable gases.

Cooling Effect: The liquid absorbs heat, making them suitable for hot processes.

Advantages:

✔ Smooth, pulsation-free operation

✔ Can handle corrosive & explosive gases (if compatible liquid is used)

✔ Low maintenance (no internal lubrication needed)

✔ Good for large-volume suction

Disadvantages:

✖ Limited vacuum range (typically down to ~30 mbar absolute, lower with boosters)

✖ Energy loss due to liquid heating (requires cooling or fresh liquid supply)

✖ Not ideal for dry gas applications (liquid contamination possible)

Common Applications:

Chemical Processing: Distillation, filtration, drying

Power Plants: Condenser evacuation

Food & Beverage: Deaeration, packaging

Paper & Pulp Industry: Deinking, suction rolls

Pharmaceuticals: Solvent recovery

Oil & Gas: Gas compression, vapor recovery

Types of Liquid Ring Pumps:

Single-Stage: Simpler, reaches ~100 mbar absolute.

Two-Stage: Higher vacuum (down to ~30 mbar).

Gas Jet + Liquid Ring: Hybrid for deeper vacuum.

Maintenance Considerations:

Liquid Quality: Avoid scaling/corrosion (use treated water if needed).

Temperature Control: Heat exchangers may be required.

Wear Parts: Impeller, shaft seals may need replacement over time.

Conclusion:

Liquid/water ring vacuum pumps are robust, versatile, and ideal for wet or dirty gas applications. While not the most efficient for high vacuums, their simplicity and reliability make them popular in many industries.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)