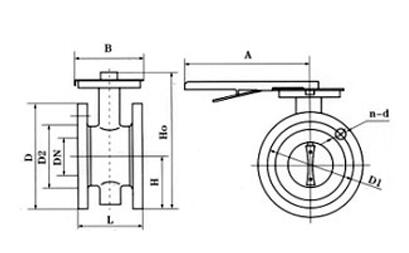

Manual flange type soft sealing butterfly valve

Soft seal butterfly valve of introduction

The material performance of the new type of high life manual flanged butterfly valve with soft seal is explained and the deficiency is also discussed.

Size:

Soft seal butterfly valves of material properties

Butterfly valve as a form of soft seal, its use is not only to let the medium in the pipeline is cut off, play the role of opening and closing, more is to make the pipeline sealing to improve. And as a soft seal butterfly valve, in the current pipeline can play a better sealing role, because this form of butterfly valve sealing surface using soft materials for design and manufacturing, and in general, the sealing performance of this material is relatively good, so can play a certain efficient sealing. Especially when the medium flow is relatively urgent, the use of this equipment can play a certain buffering effect on the medium, so that the flow rate of the medium in the pipeline to reach a balance, for promoting the flow of the medium pipe has a certain significance.

And compare with general medium, actually this kind of material is superior on sealing performance, but in durable sex respect does not occupy much advantage. In addition to the formation of the media sealing surface can achieve a certain degree of sealing, this material if used to some of the pipeline medium flow rate is relatively large, it is easy to rapidly aging, which is also the shortcomings of this material. Compared with the hard seal form in the pneumatic hard seal butterfly valve, this material still needs to be improved.

What are soft seal butterfly valve of disadvantages?

As we know, generally speaking, the soft-seal butterfly valve is not as expensive as the hard-seal butterfly valve, so why is the soft-seal butterfly valve relatively so much cheaper? What are the disadvantages of a hard – sealed butterfly valve? Next by Wenzhou Huali special valve to tell you why hard seal so cheap with its shortcomings.

Soft sealing butterfly valve is generally used in cleaner and smaller viscosity in, such as gas and liquid medium, the seal USES a soft material such as rubber, ptfe, this kind of material of the machining accuracy is not high, the price is relatively cheaper, and don’t have high pressure high temperature resistance and other properties, therefore, soft seal butterfly valve is basically will not be able to adapt to the work under the environment of high temperature and high pressure. The sealing surface of the butterfly valve is made of soft material, so its sealing performance is better, but it is also due to the use of soft material sealing surface is prone to aging, wear, leading to a very short service life.

These are some of the reasons why soft-seal butterfly valves are cheaper.

Soft-seal butterfly valve solves some problems of external connection

Butterfly valve in the form of soft seal, although in use, durability is not enough, but many times the use of soft seal butterfly valve is because of its good sealing performance. And now the soft seal butterfly valve, in fact, in its durability has been improved, the use of the external connection, strengthening the butterfly valve, so that its stability, in the side to solve some of the problems of the soft seal butterfly valve, and this connection will be introduced below.

For currently used to tube of the valve, the fixed and the connection is more important, if there is no fixed and connected guarantee, so the valve for pipeline medium truncation effect and flow control effects are not guaranteed, because there is no fixed good, it is possible the valve may become a pipeline of tools. So fixing and connecting are necessary, and there are many ways to connect, here about the clamping connection of the clamping type of soft seal butterfly valve. This is a more common way of connection, mainly rely on the clamping connection between the joint parts and the pipeline formed between the clamp and fixed, compared with this kind of connection or have some merits. The specific is to use bolts directly to the valve and both ends of the pipe through clamp together, such a connection for the connection between the pipe is also beneficial. Increases the fixed connection at both ends of the pipe so that the valve does not fall off when connected.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)