Mechanical seal of vacuum pump

Mechanical seal quality in vacuum pump for inspection procedure

People in the analysis of the vacuum pump mechanical seal leakage disadvantages, often in the design of mechanical seal to find the reason, such as: mechanical seal selection can be suitable, material selection can be correct, the specific pressure sealing surface can be correct, the choice of friction pair can be reasonable. Then leave the vacuum pump mechanical seal external conditions to find the reason, such as: to create conditions for the mechanical seal (lubrication, washing, cooling) can be suitable, the configuration of the auxiliary system can be suitable. However, with the specification of industry standards for mechanical seals, their design should be standardized. And recognizing the negative impact of poor external conditions on mechanical seals, the key factors affecting seal life seem to have shifted to other issues. That is, we often ignore the complete set of mechanical seal inspection provided by the consumer manufacturers, taking it for granted that the quality is reliable. Few people think of the lack of quality inspection, which also results in reduced seal life after use, resulting in leakage problems during static pressure testing.

It was found in the process of inspection of mechanical seal quality that the complete set of mechanical seals would also present many problems affecting the installation and use of mechanical seals. Only to strengthen the mechanical seal sampling inspection strength, can avoid a lot of unnecessary waste, at the same time reduce the consumption of accidents.

Mechanical seal for pump of basic principle

Because there is a pressure difference between the fluid inside the pump and the atmosphere outside the pump, in order to prevent slurry leakage, so the pump needs to be set up in the operation of the seal device, called the shaft seal. The types of shaft seals commonly used are: packing seal, mechanical seal, dynamic seal and floating seal. The mechanical seal has become the common seal form in all industries, and the seal form runs smoothly and reliably, bringing great economic benefits to all industries.

Basic principles of mechanical seals

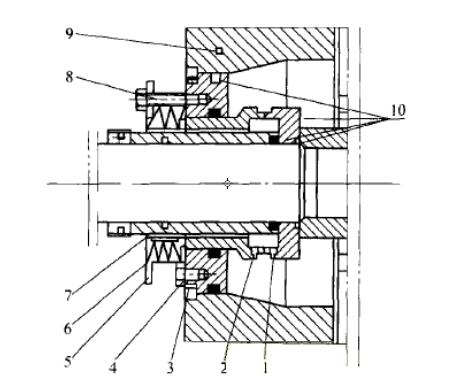

Mechanical seal is a sealing device composed of two sealing elements (static ring and moving ring), which are perpendicular to the axis of the smooth and straight surface fitting, and do relative rotation, as shown in Figure 1. It is based on the elastic member (such as spring 6) and the pressure of the sealing medium in the rotating moving ring and static ring on the contact surface (end face) to generate appropriate compression force, so that the two end faces closely fit.

FIG. 1 Schematic diagram of single end face anhydrous mechanical seal

1, moving ring 2, static ring 3, anti-pin 4, screw 5, spring seat 6, spring 7, spacer set 8, bolt 9, back shovel plate 10, sealing ring

A very thin liquid film is maintained between the end faces to achieve the purpose of sealing. The liquid film has fluid dynamic pressure and static pressure. It ACTS as a lubricant and seal. Slurry pump, desulfurization pump and other products in different working conditions can be used mechanical seal.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)