Magnetic levitation molecular pump

EVP production of magnetic levitation composite molecular pump, 100% non-contact, no friction, more than three times the service life of traditional mechanical bearing molecular pump, its various technologies have a perfect combination of stability, reliability and high efficiency. The specific performance is as follows:

——Optimization of the overall core technology (magnetic bearing, high-speed permanent magnet motor, high-strength impeller, others), to provide stable and reliable operation.

——Magnetic levitation composite molecular pump is an integrated structure, which integrates molecular pump, magnetic bearing control system, high-speed inverter, human-machine interface and other components.

Unique magnetic bearing

——The rotor suspension is realized by electromagnetic force, and the bearing has no contact, no friction and no lubrication.

——Friction free rotation between bearings and shafts maximizes energy efficiency.

——Low noise, long life.

——More than 10000 real-time signal acquisition and correction per second can accurately control the rotor axis position.

Most durable, high speed motor

——45000rpm ultra-high speed, world-class.

——The design structure is simple, suitable for all kinds of working environment, durable operation.

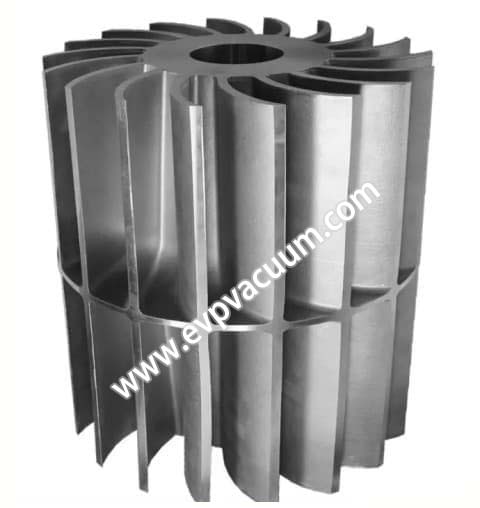

Integral high strength impeller

——High strength aviation aluminum alloy

——The design of Monte Carlo simulation combined with the actual test correction makes the molecular pump run in high efficiency and wide range.

——Five axis machining process provides high precision design and excellent durability.

Simple cooling method

——Adopt efficient cooling method (air cooling / water cooling).

Advanced intelligent control technology

——Self developed active control technology of magnetic levitation.

——Frequency conversion control technology independently developed.

——The overall on-site solution saves preparation and installation time.

——It supports multiple operation modes and communication protocols.

Maximizing revenue

——The service life is very long, generally more than 5 years.

——Stable operation, easy installation and maintenance free.

——The noise is lower than 40dB and there is no noise pollution.

——The cost advantage of domestic raw material procurement is obvious.

——Professional team, timely after-sales.

Power saving, quiet, maintenance free, intelligent control. Spin technology magnetic levitation molecular pump can effectively solve the problems of oil leakage, high noise, high vibration, high cost of maintenance and replacement of accessories, which are encountered in the current use of traditional bearing molecular pumps. To provide users with no friction, no oil, low noise, low energy consumption green low carbon environmental protection solutions.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)