Oil Diffusion Vacuum Pump Supply

Our company’s hot products oil diffusion vacuum pump supply, mainly divided into three models: KT oil diffusion vacuum pump and KN oil diffusion vacuum pump. Introduce the details of these two pumps for you below.

KT series oil diffusion vacuum pump supply

KT series oil diffusion vacuum pump is the main equipment for obtaining high vacuum (10-2 ~ 10-5pa). It is combined with valves, water cooling baffles, pipelines, mechanical vacuum pumps and other components to form a high vacuum pumping system, which can obtain (10-2 ~ 10-4pa) working vacuum. If liquid nitrogen and other cooling devices are used and baked, the ultra-high vacuum (10-6pa) can be obtained. The pump is characterized by large pumping capacity, pumping speed from 5500L/s to 120000L/s within the range of optional it added oil observation window, oil and oil outlet, pump oil temperature measuring device. KT manufacturing adopts tensile process to reduce welding seam, increase strength and reduce air release. Heater is provided with electric heating wire and electric heating plate, which can be selected when ordering. It is widely used in vacuum coating, vacuum furnace, electronics, chemical industry, aviation, aerospace, metallurgy, materials, biological medicine, atomic energy, space exploration and other high-tech fields.

Oil diffusion pump the pump oil in the oil pan is heated to the boiling temperature in the vacuum and a large amount of oil vapor is generated. Since the partial pressure of the pumped gas near the inlet is higher than that of the gas in the oil steam flow, the molecules of the pumped gas are continuously diffused into the oil steam flow. The oil vapor hits the pumped gas molecules, making the pumped gas molecules move at high speed along the direction of the steam flow. The gas molecules hit the pump wall and are reflected back again by the collision of the steam flow and flow to the pump wall again along the direction of the steam flow. After several collisions, the gas molecules are compressed to the low vacuum end, and then the steam flow from the lower nozzle is compressed at multiple levels. Finally, the oil is extracted by the front vacuum pump, and the oil vapor is cooled on the cooling pump wall and then returned to the oil pan to be heated again, so the cycle works.

Product display

| Item | KT-100 | KT-160 | KT-200 | KT-250 | KT-300 | KT-320 | KT-400 | KT-500 | |||||||

| Ultimate pressure (Pa) | 5×10-5 | ||||||||||||||

| Pumping Capacity (L/S) | 550 | 1800 | 2800 | 3500 | 4600 | 5000 | 8500 | 12000 | |||||||

| Critical fore-pump pressure (Pa) | 40 | ||||||||||||||

| Backflow rate mg/(cm2·min) | ≤3×10-2 | ||||||||||||||

| Heating time ( min) | ≤30 | ≤35 | ≤40 | ≤45 | |||||||||||

| Heating Power (kw) | 0.8-1 | 1.4-1.6 | 1.6-1.8 | 2.2-2.4 | 2.4-3 | 4~5 | 4~5 | 6~8 | |||||||

| Electric Voltage (AC)V | 220 | 380 | |||||||||||||

| Pump Oil Model | KS-3 | ||||||||||||||

| Pump Oil Volume ( L) | 0.15 | 0.45 | 0.55 | 1-1.4 | 1-1.6 | 1.4-1.8 | 3~4 | 4 | |||||||

| Cooling water consumption (L/H) | 180 | 250 | 300 | 350 | 400 | 420 | 500 | 600 | |||||||

| Inlet dimension (mm) | 100 | 160 | 200 | 250 | 300 | 320 | 400 | 500 | |||||||

| Outlet dimension (mm) | 32 | 50 | 65 | 65 | 80 | 80 | 100 | 100 | |||||||

| Recommended forepump speed (L/s) | 4 | 8 | 15 | 15 | 30 | 30 | 70 | 150 | |||||||

| Dimension (mm) |

L(Length) | 320 | 420 | 530 | 473 | 695 | 725 | 885 | 1010 | ||||||

| B(Width) | 260 | 315 | 390 | 450 | 505 | 525 | 665 | 815 | |||||||

| H(Height) | 365 | 505 | 575 | 650 | 726 | 830 | 925 | 1165 | |||||||

| Net weight (kg) | 14 | 31 | 39 | 48 | 89 | 100 | 175 | 185 | |||||||

| Item | KT-600 | KT-630 | KT-800 | KT-900 | KT-1000 | KT-1200 | KT-1400 | KT-1600 | |||

| Ultimate pressure(Pa) | 5×10-5 | ||||||||||

| Pumping Capacity (L/S) | 17500 | 20000 | 30000 | 40000 | 50000 | 60000 | 90000 | 130000 | |||

| Critical fore-pump pressure(Pa) | 40 | ||||||||||

| Backflow ratemg/(cm2·min) | ≤3×10-2 | ||||||||||

| Heating time( min) | ≤50 | ≤60 | ≤65 | ≤70 | ≤80 | ≤90 | |||||

| Heating Power(kw) | 8~9 | 9~11 | 13-13.5 | 14-16 | 17-20 | 28-30 | 38-40 | 48-50 | |||

| Electric Voltage(AC)V | 380 | ||||||||||

| Pump Oil Model | KS-3 | ||||||||||

| Pump Oil Volume( L) | 6~7 | 7~8 | 12~14 | 14-15 | 15-16 | 22 | 38 | 50 | |||

| Cooling water consumption(L/H) | 800 | 850 | 1200 | 1350 | 1500 | 2600 | 3400 | 4300 | |||

| Inlet dimension( mm) | 600 | 630 | 800 | 900 | 1000 | 1200 | 1400 | 1600 | |||

| Outlet dimension(mm) | 150 | 160 | 200 | 200 | 300 | 300 | 320 | 320 | |||

| Recommended forepump speed (L/s) | 300 | 600 | 600 | 600 | 1200 | 1200 | 1200 | 2500 | |||

| Dimension (mm) |

L(Length) | 1145 | 1170 | 1520 | 1843 | 1990 | 2235 | 2556 | 2900 | ||

| B(Width) | 975 | 1010 | 1275 | 1283 | 1290 | 1750 | 1950 | 2100 | |||

| H(Height) | 1444 | 1275 | 1870 | 1950 | 2220 | 2465 | 2950 | 3355 | |||

| Net weight (kg) | 375 | 420 | 670 | 830 | 990 | 1500 | 2150 | 2500 | |||

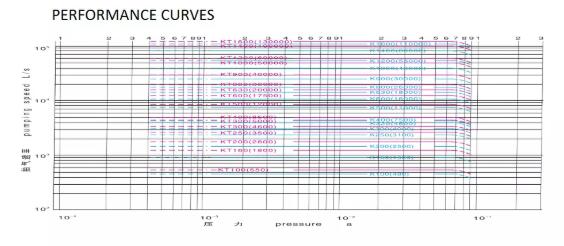

Performance curve

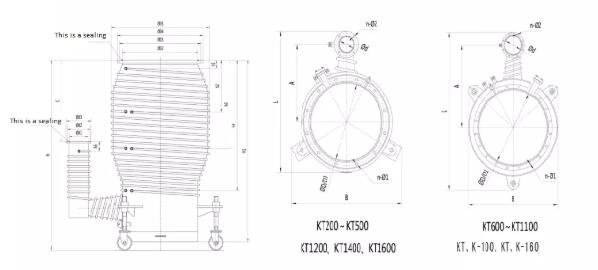

Installation size

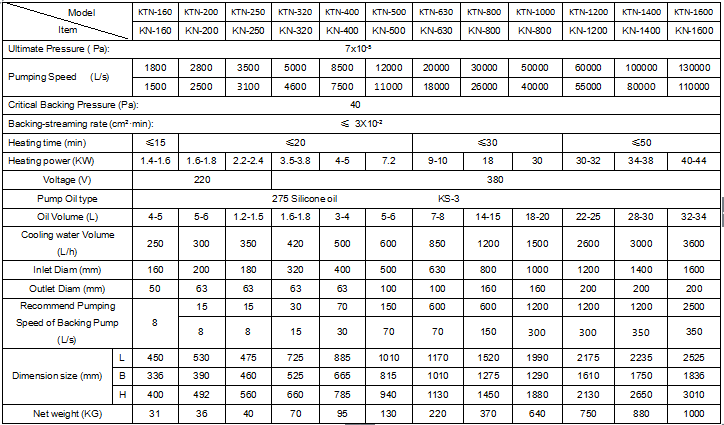

KN series oil diffusion vacuum pump supply

KN series oil diffusion vacuum pump is used to obtain high vacuum (10-1-10-5pa) of the main equipment. The pump is characterized by large pumping capacity, pumping speed from 1500L/S to 130000L/S range for choice; It is added oil observation window, injection and discharge port, pump oil temperature control overheating protection device, cooling water temperature overheating alarm device and multiple heating rod inserted into the pump in parallel combination, can not stop to replace the heating rod, so the heating time is short.

Low return flow of oil steam, no external water-cooling baffle, common diffusion pump oil, its return flow is 1 10-3 mg/cm 2· min, if 275 silicone oil, return oil can be reduced to 1 10-4 mg/cm 2· min, the limit vacuum is high, less than 10-6pa

The pump adopts tensile process to reduce welding seam, increase strength and reduce air release.

It is widely used in vacuum coating, vacuum furnace, electronics, aerospace and other high-tech fields.

Product display