Mexico Piston Vacuum Pump

Mexico piston vacuum pump, full name sliding valve oil seal mechanical vacuum pump, referred to as sliding valve pump, is a variable volume gas transmission pump, its application scope and use conditions are basically the same as rotary vane pump.

Mexico piston vacuum pump has a much larger capacity than rotary vane vacuum pump due to its structural characteristics, so it is more widely used in large-scale vacuum equipment. The basic types of piston vacuum pumps can also be divided into single-stage and double-stage. Among them, the limit pressure of small pump in single stage pump is generally not more than 0.6 Pa, and that of large pump is not more than 1.3 PA (Junguan gas town); and that of double stage pump is not more than 0.06 Pa (Guan gas town). Piston vacuum pumps with pumping speed greater than 150L/s are mostly single-stage pumps.

Because the rotating mass of the piston vacuum pump has greater eccentricity and has no good mass balance, it will produce greater vibration in operation. At the same time, it is difficult to achieve the complete balance of inertia force of the sliding valve pump because the trajectory of the revolving center of mass of the sliding valve pump is a complex closed curve. This limits the rotational speed of the sliding valve vacuum pump, which is generally controlled at 350-600r/min and can reach more than 1000r/min in some cases.

Mexico Piston Vacuum Pump Working Principle

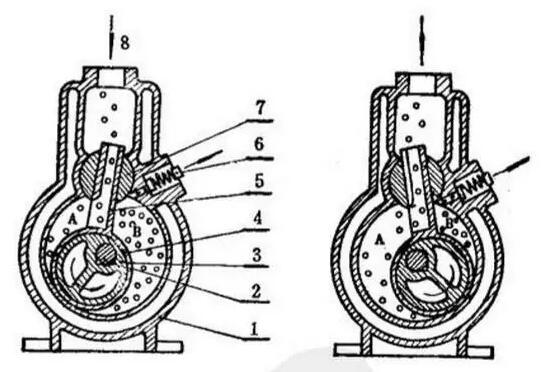

The main structure of piston vacuum pump includes pump body, eccentric wheel, slide valve assembly and guide rail. Let’s understand its working principle through a diagram.

The driving shaft concentric with the pump chamber drives the eccentric wheel to rotate, and the eccentric wheel drives the sliding valve ring to move, so that the sliding valve stem slides up and down the guide rail and swings left and right. The slide valve divides the pump chamber into two parts, A and B. When the driving shaft rotates in the direction shown in the figure, the volume of cavity A increases and the pressure decreases, and the gas enters cavity A through the inlet and the slide valve stem (the opening on one side of cavity A), which is in the process of inspiration. The sliding valve continues to run clockwise to the upper left position. When the volume of cavity A reaches its maximum, the intake is isolated from cavity A and the suction process ends. At the same time, the volume of cavity B is in the process of constant reduction and compression of gas. When the gas pressure in B chamber reaches the exhaust pressure, push the oil seal exhaust valve and start to exhaust. When the sliding valve is positioned directly above, the exhaust end (the volume of cavity A is also at its maximum), and a new cycle begins.

The main structure of piston vacuum pump includes a series of components such as pump body, eccentric wheel, slide valve ring, slide rod and guide rail. Similar to rotary vane vacuum pumps, slide valve pumps are equipped with air ballast valves, with air ballast holes open near the exhaust outlet or on the end cap to remove gas containing condensable vapor, and oil and gas separators are installed at the outlet of the pumps to reduce the loss of pump oil and pollution to the environment.

In addition to the distinction of single-stage and double-stage, the sliding valve vacuum pump also has the distinction of single cylinder, double cylinder and three cylinders. Among them, the three-cylinder sliding valve pump solves the mass balance of the sliding valve better, improves the vibration of the pump better, and has a relatively high speed.

Mexico Piston Vacuum Pump Application

Piston vacuum pump can be used alone as rotary vane vacuum pump, but also as the front pump of diffusion pump, oil booster pump, Roots pump and other vacuum pumps. Compared with rotary vane pump, piston vacuum pump is more durable. It is widely used in vacuum coating, vacuum heat treatment, vacuum sintering, molecular distillation and aviation simulation experiments. However, in the case of water vapor, dust and other media environment, it is necessary to install a filter device, also can not be used for flammable and explosive gas environment and compressed conveying gas. At the same time, limited by the characteristics of oil-sealed mechanical vacuum pumps, in some areas of clean environment, such as semiconductor, petrochemical, etc., applicability is less than some dry vacuum pumps.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)