Vacuum pumps

Vacuum Pump of Brief Introduction

When designing or operating a vacuum system, it is important to understand the function of a vacuum pump.We will review the most common types of vacuum pumps, how they work and where they are in the system.We will pay more attention to these pumps for the next few months.

Pump type (by working pressure)

Vacuum pumps are classified according to their working pressure range, so they are classified as main pumps, booster pumps or auxiliary pumps. There are several different types of pumps in each pressure range, each with different technology, and each pump has some unique advantages in pressure capacity, flow rate, cost and maintenance requirements.

Next, what is the main pump of the vacuum pump?

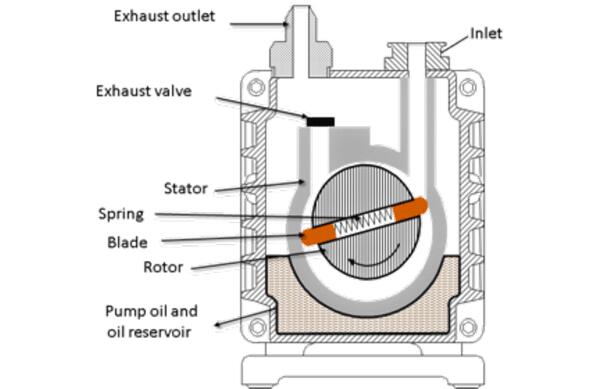

Rotary vane pump

In a rotary vane pump, gas enters the inlet and is captured by an eccentrically mounted rotor that compresses the gas and transfers it to the exhaust valve.The valve is spring loaded and allows gas to be discharged beyond atmospheric pressure.Oil is used to seal and cool the blades.The achievable pressure of the rotary pump depends on the series used and its tolerances.Two-stage design can provide pressure of 1 x 10-3 mbar.The pumping speed is 0.7 to 275 m3 / h (0.4 to 162 °3 / min).

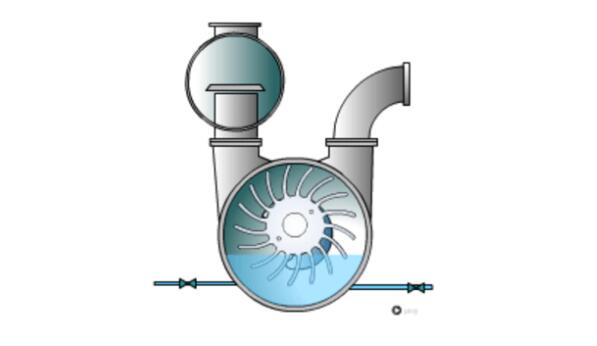

Liquid ring pump

Liquid ring pump, Compress the gas by rotating the eccentric vane impeller located in the pump housing.The liquid is fed into the pump and accelerated by the centrifuge to form a moving cylindrical ring, which is placed on the pump shell.The liquid ring forms a series of seals in the space between the impeller blades, forming a compression chamber. The eccentricity between the rotating shaft of the impeller and the pump housing results in periodic changes in the volume surrounded by the blade and the ring.The compressed gas is discharged through the end of the shell.The pump has a simple and robust design because the shaft and impeller are the only moving parts.It is very tolerant of process disturbances and has a large capacity range. It can provide 30 mbar of pressure with water of 15 degrees C (59 degrees F), and other liquids can reduce pressure.The pumping speed is 25 to 30 000 m 3/h (15 to 17 700 ft 3/min).

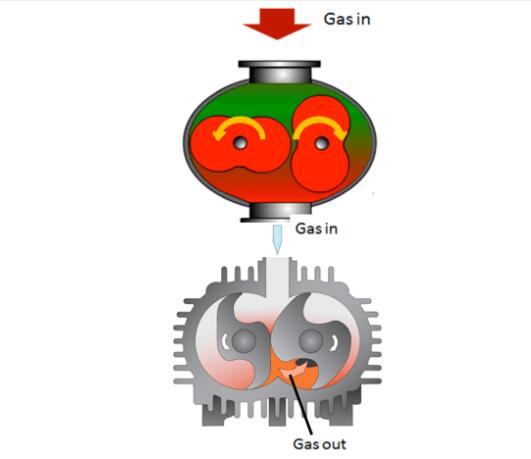

Roots pump

The root pump is mainly used as a vacuum booster to remove large amounts of gas. The two blades engage without contact and reverse rotation to continuously transmit gas in one direction through the pump. It improves the performance of the main pump/front stage pump, increases the pumping speed by about 7:1, and increases the limit pressure by about 10:1.Roots pumps can have two or more blades.Typical limit pressure < 10-3 torch (combined with main pump).The pumping speed can reach 100000 m3 / h (58860 ft 3/min).

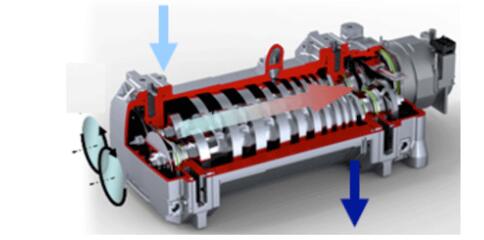

Screw Pump

Screw pump (figureUse two rotary screws, one for the left hand and the other for the right hand.It has no contact.The rotation conveys the gas from one end to the other. The design screw reduces the space between them as the gas flows, and it is compressed, resulting in lower pressure at the inlet end.The pump has the advantages of high handling capacity, good liquid handling capacity, and can withstand dust and harsh environment.A typical ultimate pressure of about 1 x 10-2 stents can be achieved.The pumping speed range is as high as 750m3/h (440f3/min).

Various types of vacuum pumps are briefly described here, but more detailed discussions are needed to fully understand the advantages and limitations of each technology.

Vacuum pump is not one of the most important parts of vacuum furnace.The quality of the process and implementation we run depends on how these systems work.