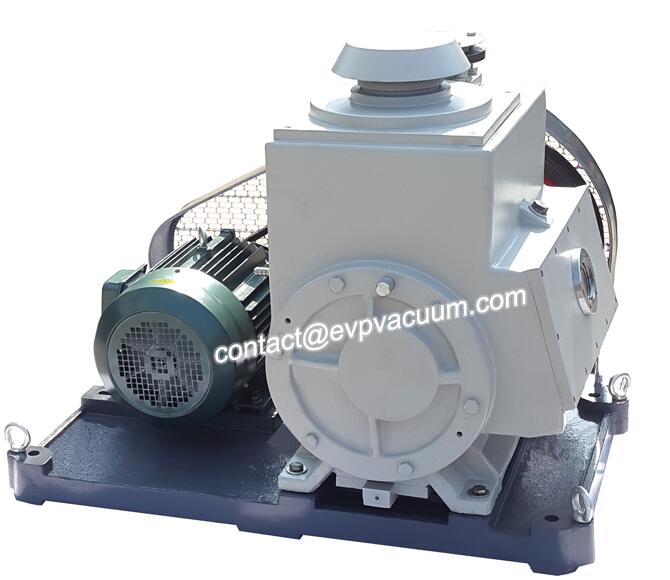

Rotary vane vacuum pumps

Rotary vane vacuum pump definition: The eccentrically mounted rotor in the pump is tangent to the stator fixed surface, and two (or more) vanes slide in the rotor slot (usually radial) and contact the inner wall of the stator to divide the pump chamber into several A variable volume, rotary variable volume vacuum pump. Usually, the gap between the rotary vane and the pump chamber is sealed with oil, so the rotary vane vacuum pump is generally an oil-sealed mechanical vacuum pump. Its working pressure range is 1.0×10^5–1.33×10^-2(Pa), which belongs to low vacuum pump. It can be used alone or as a foreline pump for other high vacuum pumps or ultra high vacuum pumps. It has been widely used in the production and scientific research departments of metallurgy, machinery, military, electronics, chemical, light industry, petroleum and medicine.

There are many types of rotary vane vacuum pumps. The domestic rotary vane vacuum pumps include 2X rotary vane vacuum pump, X rotary vane vacuum pump, 2XZ rotary vane vacuum pump, XD rotary vane vacuum pump and WX oilless vacuum pump. Introduce its features and uses as follows:

2X rotary vane vacuum pump

1.2X rotary vane vacuum pump overview :

The 2X rotary vane vacuum pump is a two-stage structure. Its working performance consists of two parts: high pressure stage and low pressure stage. Its suction port is connected with vacuum vessel or vacuum equipment. During operation, the gas in the container will be inhaled and discharged in large quantities. When the equipment is vacuumed, the high-pressure stage exhaust valve piece will be closed, and the gas sucked in the high-pressure stage will be transferred to the second stage and sucked and discharged through the second stage, so that the vacuum equipment can obtain a certain vacuum. The technical parameters of the pump are 6×10-2pa. According to the user’s usage, it can be equipped with a vacuum booster pump, and the 2X rotary vane vacuum pump is used as the foreline pump. Because the pumping force of the booster pump is strengthened, the fore pump is continuously pumped out, which can make your equipment obtain a higher vacuum. .

2, 2X type rotary vane vacuum pump use and scope of application:

Due to the high development of modern science and technology, the application of 2X rotary vane vacuum pump covers various scientific fields and various enterprises and institutions. Its main performances are as follows:

1. It can be used for scientific research, production and teaching by scientific research institutions, universities, industrial and mining enterprises such as metallurgy, chemical industry, light industry, petroleum, medical, pharmaceutical, printing and dyeing, electrical appliances, electric vacuum, semiconductor, food, atomic energy, textile, etc.

2. Since the 2X rotary vane vacuum pump is made of ferrous metal and is relatively precise, the whole pump work is associated with oil, so it is not suitable for removing oxygenated, toxic, explosive. The various gases that etch ferrous metals and chemically catalyze vacuum oils should not be used as compressors and transfer pumps. If there is a pump with a gas ballast device, a certain amount of condensable vapor can be removed.

3, 2X rotary vane vacuum pump can be used to directly obtain vacuum work below 10-3 Torr vacuum, and with other vacuum equipment to obtain a vacuum degree of 10-3 Torr or more vacuum.

4, 2X rotary vane vacuum pump is generally used in an environment that is not at a temperature of 5 ° C and a relative temperature of not higher than 90%.

According to the user’s use, it can be equipped with a vacuum booster pump, which is used as a foreline pump. Because the pumping force of the booster pump is strengthened, the fore pump is continuously pumped out, and the equipment can obtain a higher vacuum.

X-type rotary vane vacuum pump

1. X-type rotary vane vacuum pump Introduction and use :

The X-type rotary vane vacuum pump is a single-stage rotary vane vacuum pump. It is the first domestic new product that can remove a large amount of water vapor. The pump itself has an oil regeneration device and a reliable gas ballast device, which prolongs the service life of the pump oil. X-type rotary vane vacuum pump is the basic equipment used to extract the gas from the sealed container. It is suitable for electronic device manufacturing, vacuum drying, filtration, impregnation, coating, welding, smelting and laboratory equipment (handicraft special pump). . It can be used alone or as a foreline pump for booster pumps or diffusion pumps, but it is not suitable for pumping from one container to another. When removing an oxygen-containing, explosive, corrosive ferrous metal that is chemically reactive with vacuum oil, such as water, gray, etc., an additional device should be added. The main models are: X-100 single-stage rotary vane vacuum pump and X-150 single-stage rotary vane vacuum pump.

2.X-type rotary vane vacuum pump features:

a. Compared with the XD series single-stage vacuum pump, the ultimate vacuum is high. For the slide valve vacuum pump, the noise can be controlled by adjusting the muffler needle valve. Since the rotor has a small eccentric mass and balances the rotor, the vibration is small.

b. X series rotary vane vacuum pump has high pumping efficiency.

c, X series rotary vane vacuum pump performance is good.

The X series rotary vane vacuum pump has a specially designed gas ballast device to charge the exhaust chamber with dry gas, which greatly reduces the partial pressure of steam in the exhaust gas. When it is below the saturated vapor pressure at the pump temperature, it can be discharged outside the pump with the charge air to avoid condensation in the pump.

d, X series rotary vane vacuum pump is equipped with temperature control water quantity regulating valve.

When the pump is working, the pump can adjust the water pressure to adjust the pump temperature to 75oC±5oC, so as to increase the discharge pump, but the pump temperature should not exceed 80oC (tank temperature measurement point).

e, X series rotary vane vacuum pump has oil-water separator.

It allows impurities and condensate in the pump oil to accumulate to the bottom of the water separator, and is discharged outside the pump through a drain valve installed at the bottom.

2XZ rotary vane vacuum pump

2XZ rotary vane vacuum pumps summary:

2XZ rotary vane vacuum pump is a two-stage direct connection structure. Its working performance consists of two parts: high-pressure stage and low-pressure stage. Its suction port is connected with vacuum equipment. During operation, a large number of gases in the container are inhaled and discharged. When the equipment is vacuum, the high-pressure stage exhaust valve is closed. The gas in the high-pressure stage inlet will be transferred to the second stage, and the vacuum equipment will be inhaled and discharged through the second stage. Certain vacuum can be obtained. The technical parameters of 2XZ rotary vane vacuum pump are 6*10-2 Pa. The pump is connected with the motor, with high speed, small size, compact structure and convenient fluidity. It can be used in the manufacture of electric vacuum devices, the manufacture of thermos flasks, vacuum welding, printing, plastic absorption, refrigeration equipment repair and instrumentation matching. Because of its small size, light weight and low operating noise, it is more suitable for laboratory use.

2XZ rotary vane vacuum pumps characteristics:

The 2XZ rotary vane vacuum pump has the advantages of small volume, light weight, low noise and easy starting. In addition, there are measures to prevent oil return (2XZ-8) and no measures to prevent oil leakage from polluting the site.

Rotary vane vacuum pumps of type A and 2XZ are the basic equipment for obtaining vacuum. They can act independently, and can also be used as front-stage pumps and pre-pumps for various high vacuum systems.

The air intake of B and 2XZ rotary vane vacuum pumps shall be continuously open to the atmosphere for no more than three minutes.

C. Pumps are not suitable for extracting gases containing particulate dust, which are corrosive to metals and react chemically with pump oil, in order to contain excessive oxygen and explosive gases.

D. Pumps may be used as compression pumps or conveyor pumps.

The working conditions of E and 2XZ rotary vane vacuum pumps are as follows: the relative temperature is not more than 90% in the temperature range of 5 40 and the inlet pressure is less than 1333 3a, which permits long-term continuous operation.

F. When installing and connecting the power supply, according to the stipulation of the motor label, the rotation direction of the motor should be in accordance with the arrow direction on the support.

G. The diameter of the pipeline of the continuously pumped container should be no less than the diameter of the intake port of the pump, and the pipeline should be short and less elbows, while paying attention to the leakage of the pipeline.

H. The oil level should be checked before starting each time. It is advisable to inject oil to 4/5 of the diameter of the oil mark glass when stopping the pump.

I. Clean SY1634-701 vacuum pump oil is used for pumping oil.

J, 2XZ type rotary vane vacuum pump can start next time in open air or any vacuum degree. If the starting of XZ-1 single-stage pump is difficult, the intake pipe plug cap can be removed to start, and then put into operation.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)