Advantages & Disadvantages of dry screw vacuum pump

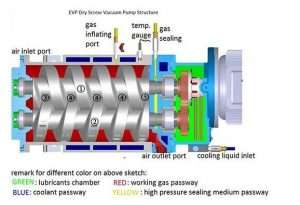

Dry screw vacuum pump is mainly use a pair of screws, which characteristics is calibrating or balancing the dynamic balance through its two screws, supported by the bearing, installed in the pump housing, there is a certain gap between each screw to avoid fricting between each other during working. To make sure its smooth operation and low noise. There is no lubricating oil in working chamber.Dry screw vacuum pump can extract the gas which containing large water vapors and a small amount of dust and the ultimate vacuum much more higher.

Dry screw vacuum pump, which uses a pair of screw in the chamber for synchronous high-speed reverse rotation of the suction and exhaust air suction device. This feature remedy the defects of oil-sealed vacuum pump, we called it is an upgraded version of the oil-sealed vacuum pump. However, the cost of dry screw vacuum pump become its main disadvantages. The following introduces its advantages and disadvantages:

Advantages of dry screw vacuum pumps:

1.working chamber and screw rotor surface has the anti-corrosion coating to make sure the pump can work in harsh conditions;

2.The gas in pump chamber without compression can be suitable for extracting condensable gases;

3.No oil, no drip or leak;

4.Simple structure, easy maintenance;

5.The extracted gas directly discharged from the pump body, no water polluting and keep clean environment, the gas recovery much more convenient.

Disadvantages of dry screw vacuum pumps:

1.Due to its difficult process of working and also as a new products in the world which resulted in the price is very expensive;

2.Not suitable for extracting explosive gas;

3.Not suitable for pumping hyperoxic gas.

With the development of the industry in china, the requirements for a clean vacuum environment are getting more serious in semiconductors, liquid crystal displays industry, etc. While the traditional oil sealed vacuum pumps can not meet such demands. Dry screw vacuum pump due to its wide suction capacity range, simple and compact structure, suction chamber components without friction, long life, low energy consumption, no oil pollution, etc., can be used in more and more manufacturing and application conditions. In developed countries, such as Europe, America and Japan, dry screw vacuum pumps have already replaced more traditional oil pumps in many fields.

For more news about dry screw vacuum pumps, please read this link: https://www.evpvacuum.com/newsview-255-374-Difference_Between_Dry_Screw_Pump_Oil_Lubricated_Screw_Pump.html

tags: dry screw vacuum pump

Edited by Catherine Qin / EVP Vacuum Solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)