Vacuum Degassing

Vacuum degasser is a device that uses a vacuum pump to evacuate the tank body to cause a negative pressure. The mud is sucked into the tank body and then processed to further separate the gas in the mud. It is suitable for various types of mud purification systems, and plays an important role in restoring the specific gravity of the mud, stabilizing the viscosity of the mud, and reducing drilling costs.

Application areas:

It is suitable for degassing distilled water and deionized water in pharmaceutical research, pharmaceutical and chemical industries. It is suitable for various types of mud purification systems, and plays an important role in restoring the specific gravity of the mud, stabilizing the viscosity of the mud, and reducing drilling costs.

Technical indicators:

1. Temperature control range: 37 ℃ — 45 ℃.

2. Resolution: 0.1 ° C.

3. Temperature control accuracy: ± 0.5 ℃.

4. Vacuum control range: 0.02Mpa ~ 0.05Mpa.

5. Resolution: 0.01Mpa.

6. Processing solution volume: 7 liters or 21 liters.

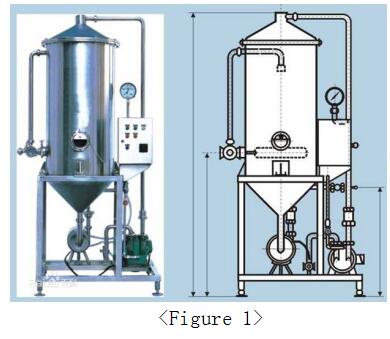

In this application, due to the low vacuum requirements, 2BV series single-stage water ring vacuum pumps are usually used. EVP brand 2BV water ring pumps have the advantages of superior performance, durability, beautiful appearance and reasonable price, which are vacuum degassing applications’ best choice. The simple application diagram is as follows (Figure 1), and the commonly used water ring pump is shown in Figure 2.

Keywords:vacuum degassing, vacuum pump, liquid ring vacuum pump

Edited by: Emily Fu / Shanghai EVP Vacuum Technology Co., Ltd.