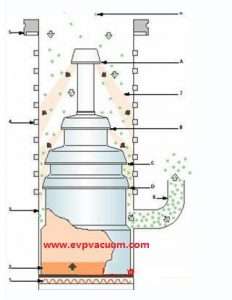

Diffusion pump oil return process diagram

The oil vapor of diffusion pump is completely move radially down the pump chamber. Due to random scattering or directional radiation, some molecules of steam ejected from the nozzle also move toward the pump port. This process we called Backflow. Backflow is the main contamination of diffusion pump vacuum system !

Therefore, in order to reduce the backflow, an appropriate trapping device is usually added between the nozzle and the pumped system. For example, A water-cooled trap which can reduce the return flow by 50% while the pumping speed is only about 10% reduction. Unfortunately, the higher the efficiency of trapping and returning, the greater the effect on the pumping speed. Such as, a device that can completely capture the reflux with water or liquid nitrogen cooling, may reduce pumping speed by 30% !

tags: Diffusion pump

Edited by Catherine Qin / EVP Vacuum Solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)