Molecular Pump Operation for Influence of Magnetic Field Environment

Many devices generate magnetic fields when they work. For example, the magnetic field strength of a household refrigerator is about 10 Gauss (1mT), and the magnetic field strength of an MRI (nuclear magnetic resonance) can even be as high as 3T; although measures such as shielding can be taken, there may still be The leaking stray magnetic field has a bad influence on the molecular pump working nearby.

Magnetic field on turbo molecular pump of possible influence

When the rotor of a turbo molecular pump rotates in a magnetic field, eddy currents are created. These currents tend to hinder the rotation of the rotor and cause the power of the motor to increase. Since the pump rotor is not in contact with the stator, the heat and additional power generated by the eddy currents are dissipated mainly through radiation. As a result, the rotor may overheat even if the pump body and other stationary parts remain cold. To confirm the effect of magnetic fields on the operation of the molecular pump, the following tests were designed and performed by the Karlsruhe Institute of Technology (KIT) in Germany:

Test conditions and devices

The molecular pump under test, a model TwisTorr304 FS CFF6, uses a pair of Helmholtz coils (120 cm in diameter) to generate a uniform magnetic field surrounding the entire pump.

The molecular pump under test uses a dry vortex pump as the front stage, and the inlet pressure of the molecular pump is pumped to below 1E-3 mbar (below this pressure, the heat convection is almost zero, and the heat of the molecular pump rotor can only be transferred by radiation out a small portion).

Use 20°C cooling water to continuously cool the molecular pump; the controller of the molecular pump will automatically adjust the motor current to keep the rotor running at a constant speed. Use an infrared thermometer installed at the port of the molecular pump to measure the rotor temperature of the molecular pump under test. The temperature of the stator is measured using a PT100 RTD connected to the molecular pump housing.

Testing process

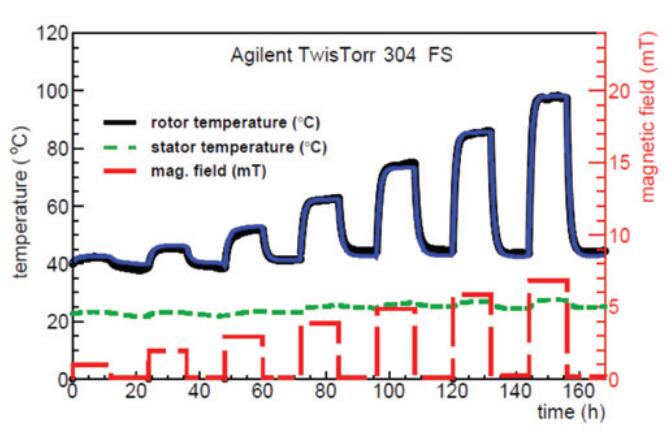

During the test, the turbo pump continued to run at full speed. The initial magnetic field was set to 1mT, and the pump was run for 12 hours in this field to stabilize the rotor temperature; then the magnetic field was turned off and the rotor was run for another 12 hours to cool the rotor; then the magnetic field was set to 2mT, respectively, and the previous steps were continued. Test until the magnetic field increases to 7mT.

Testing Result

As shown in the above picture, when the magnetic field gradually increases, the equilibrium temperature of the rotor of the molecular pump under test also increases. When the magnetic field strength is 7mT, the equilibrium temperature rises to about 100 degrees Celsius (the maximum allowable temperature of the Agilent molecular pump is 120 degrees) .

In addition, KIT used this test platform to test another molecular pump of other brands. A series of comparative tests showed that the equilibrium temperature of the rotor of Agilent molecular pump under the same magnetic field conditions was significantly lower (about 40 degrees lower at 5mT) .

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)