Liquid Ring Vacuum Pump in Vacuum Consolidation

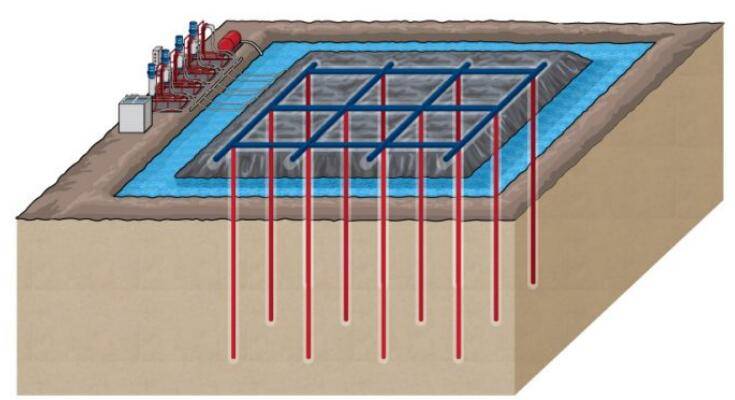

The invention discloses a method for soil dehydration and drying or vacuum solidification, belonging to the field of soil dehydration and foundation reinforcement. It inserts a specially designed vacuum plate in the soil, then removes the moisture in the soil through the vacuum preloading process, and finally removes the sealing film, and continues to pump it with an EVP water ring vacuum pump to accelerate the flow of air in the soil.

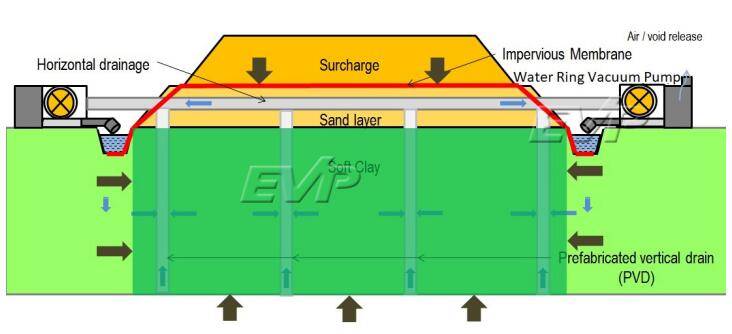

The vacuum preloading method is to lay a sealing film on the surface of the foundation, and suction vacuum it through a special EVP vacuum equipment, so that a negative pressure is formed in the sand cushion under the sealing film and in the vertical drainage channel in the soil mass, which accelerates the discharge of pore water, so that the soil mass can be discharged. Consolidation and strength-enhancing vacuum reinforcement of soft soil foundations.

The vacuum preloading method is suitable for reinforcing silt, silty soil and other soft clays that can be consolidated by drainage and can form negative pressure boundary conditions. The consolidation process of soil under the action of vacuum is a process in which the pore water pressure decreases and the effective stress increases under the condition of constant total stress. The vacuum preloading method is shown in the figure below:

Process features:

1.Within the scope of the vacuum preloadingarea, since the vacuum degree distribution is uniform, the reinforcement effect of vacuum curing is better than that of the stacking preloadingmethod under the same conditions.

2.During the reinforcement process, the soil body is not only compressed vertically, but also shrinks laterally, which will not cause lateral extrusion of the soil body, which is especially suitable for the reinforcement of ultra-soft soil foundations.

3.The vacuum preloadingmethod does not need to apply pressure in stages during construction. It can be quickly applied to more than 80kPa at one time without causing instability and damage to the foundation. Compared with the heap preloading, the loading is faster and the construction period can be significantly shortened. At the same time, it is only necessary to stop the air extraction when unloading, so the construction is simple and easy. For vacuum pump selection, please freely contact EVP VACUUM.

4.There is no need for a large amount of piling materials, which can avoid the construction of construction passages for the transportation of piling materials in and out, and the transportation tension caused by the surrounding roads, and reduce the construction interference; there is no noise, no vibration, and no environmental pollution during construction.

5.The construction machinery and equipment are simple and easy to operate; the construction is convenient, the operation efficiency is high, and the reinforcement cost is low, which is suitable for large-scale foundation reinforcement and easy to popularize and apply.

6.It is suitable for foundation reinforcement in narrow areas and near slopes

Preparation before vacuuming

1.Lay out the filter pipeline

After all the plastic drainage boards in the reinforcement area are installed, the filter tubes are laid out according to the design requirements. First, the filter tubes are arranged and connected, and the joints are tied firmly with iron wires. 25 cm, and then dig a trench while burying the pipe into the trench, the depth of the trench is about 20 cm, and fill it with medium-coarse sand. The connection between pipes should be spliced with skeleton rubber hose, the length of the sleeve should not be less than 10 cm, and it should be tied with lead wire to ensure firmness. In order to prevent the lead wire joint from piercing the sealing film, the lead wire joint should be buried in the sand layer downward during the laying process. At the same time, when burying the filter tube, make sure that the filter membrane on the filter pipeline is not damaged.

Preparation before vacuuming” />

Preparation before vacuuming” />

2.Site leveling and cleaning

Clean up debris, gravel, etc. in the site to avoid puncturing the sealing film.

3.Excavation of lamination trenches

For lamination trenches, mechanical trenching or manual trenching can be selected as required. The depth of the film ditch must exceed the permeable soil layer on the edge of the reinforcement area, and the depth should not be less than 50 cm. See the left image below.

When there is a permeable and breathable soil layer around the reinforcement area, a clay sealing wall should be built around the reinforcement area. The thickness of the clay sealing wall should not be less than 1.2 meters, the clay content of the wall after mixing should be greater than 15%, and the permeability coefficient should be less than 1 ×10^-5 cm/sec.

4.Laying of sealing film

The sealing film is generally 2 to 3 layers. Before laying the film, the drainage cushion should be carefully cleaned and leveled, the shells and stones with sharp corners should be removed, and the holes left by the plastic drainage board should be filled and leveled. The hole should be carefully checked and filled in time, and the next layer should be laid after it meets the requirements. The laying of the sealing film should be carried out during the day, according to the downwind direction, and the wind force should not exceed level 5. The length and width of the sealing film should exceed 4 meters on both sides of the reinforcement area. The sealing film should be embedded in the impermeable clay layer in the lamination trench. The backfill of the film ditch should use cohesive soil free of debris

5.When filling the water-covered enclosure, installing the vacuuming equipment, and testing the vacuuming equipment, a trial operation should be carried out. The installation should be kept stable and the power supply should be connected firmly to the filterpipeline.

6. After the water-covered sealing film is embedded in the lamination groove, and it is basically confirmed that there is no hole in the sealing film, water can be covered on the sealing film.

Vacuum pumping: After several days of test pumping, after the vacuum degree meets the design requirements, it should be reported in time. Please start the vacuum pumping and timing after the supervision and inspection. Shanghai EVP Vacuum Technology Co., Ltd. has provided a lot of high-performance and quality water ring vacuum pumps and vacuum units for the vacuum consolidation application.

EVP’s design and recommendations for the industry:

1 When the air inlet of the vacuum pumping equipment is closed, the vacuum pressure should not be less than 96Kpa.

2 The control area of each vacuum pumping equipment should be 900~1100 square meters, and the vacuum pumping equipment should be evenly arranged around the reinforcement area.

3 The sealing film should be checked frequently during the extraction, and repaired in time if it is damaged.

4.The opening amount of vacuum equipment should exceed 80% of the total.

5.Stop the pump and unload: analyze and calculate the monitoring data during the foundation reinforcement process, and stop the pump and unload after meeting the design requirements.

For the selection of water ring vacuum pumps in this Vacuum Consolidation applications, please kindly contact Shanghai EVP Vacuum Technology Co., Ltd., which has been engaged in the vacuum industry for 24 years and has a professional technical team. Feel free to inquire at any time, we will try all best to support you.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)