Monoblock liquid ring vacuum pump

2BV monoblock liquid ring vacuum pump

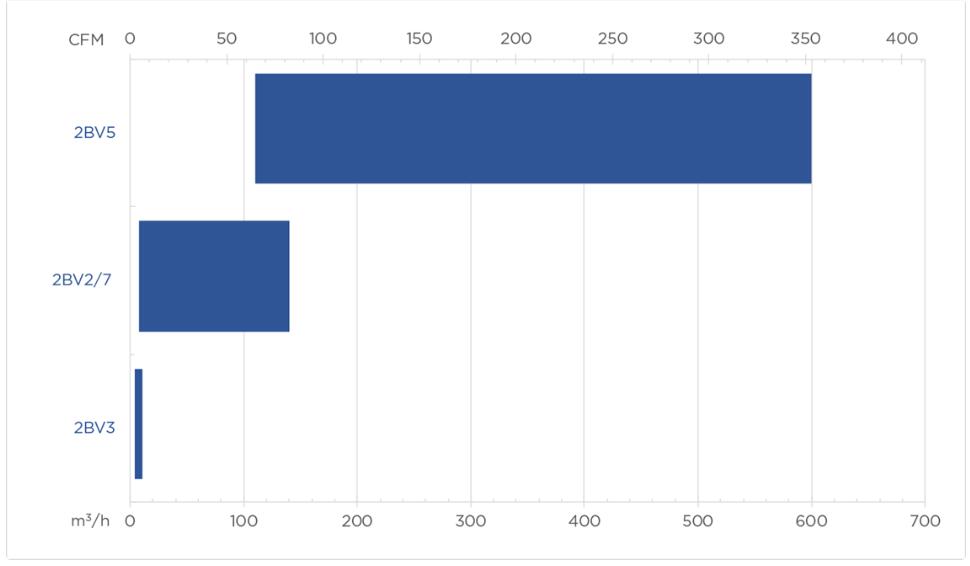

Capacity 2 to 80 ACFM (4 to 140 m3 / h)

The 2BV monoblock liquid ring vacuum pump series is designed to provide superior performance for a wide range of applications. The combination of innovation and economy, high vacuum capacity, extra water treatment capacity and compact size makes it an ideal machine for industries such as plastic manufacturing and medical technology.

Combine quality construction with reliability

The simple structure of the 2BV is combined with excellent materials to make an extremely reliable machine. These pumps have non-corrosive compression Chambers including stainless steel body, shaft and end plates. These pumps have excellent resistance to corrosion and corrosive media. In addition, the use of non-corrosive materials, even after a long period of inactivity, can ensure the free rotation of a moving part (rotor).

Fast delivery worldwide

The 2BV is equipped with a very versatile electric motor that can be installed anywhere in the world at any time. The motor features a wide voltage range, IP55 housing and is suitable for 50/60 Hz service. It also complies with international standards, including UL and CSA.

2BV monoblock liquid ring vacuum pump main features

Compact and lightweight monoblock pump and motor design

Corrosion resistant

Quiet operation

No additional substrates, couplings or guards are required, which increases the cost, complexity and overall size of the installation

The design conforms to ATEX 94/9 EC

Most distribution centers and major manufacturing locations are in stock

2BV monoblock liquid ring vacuum pump technical parameters

Suction: 2 to 80 ACFM (4 to 140 m 3 / h)

Vacuum range: to 1 inHgA (to 33 mbar abs).

Discharge pressure range: up to 33.3 LBS/sq. in. (absolute pressure to 2.3 bar)

Differential pressure: up to 19 psi (up to 1.3 bar)

Shaft seal: single function mechanical seal

Structural materials: cast iron/bronze, stainless steel

Factory service

The certified service center is the only center authorized to provide OEM parts, factory trained technicians and patented upgrade services to provide quality service and maintenance at competitive prices.

Some companies claim to provide services but take shortcuts, reusing parts and not repairing products to OEM specifications. Consider other service stores – why take the risk? Substandard maintenance can lead to costly downtime, pump and system failures, and lost production.

On-site service

A certified field service team can complement your internal maintenance efforts and keep the liquid-loop vacuum and compressed gas system running efficiently and reliably. Certified on-site services are factory trained and delivered worldwide to help you determine the required repairs, avoid costly downtime and increase the average time between failures.

Complete system analysis, troubleshooting and audit

fiberscope

Capacity test

Vibration analysis

System startup and operator training