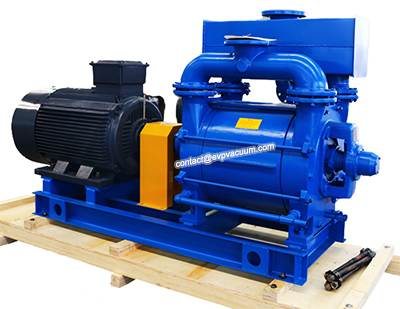

New liquid ring vacuum pump develop

New liquid ring vacuum pump developand design

Liquid ring vacuum pump and water ring refrigeration compressor are commodities with high energy consumption and low efficiency. They are objective facts. Small pumps are usually 40-45% and large pumps are 50% or slightly higher. Such low efficiency is very incompatible with the state’s regulations on electrical products and the current situation of power energy anxiety in China.

Therefore, it is necessary to select the reliability design method as early as possible, establish mathematical modeling model for the main geometric parameters of the most important centrifugal impeller which endangers the efficiency of the pump, the starting and ending positions and the total area of the suction and discharge air holes, carry out reliability design, select the best composition plan of the main parameters, and select the relevant basic theory and calculation method of the vapor-liquid two-phase flow to carry out the design Case, try to avoid the vortex damage of water ring, beyond the goal of improving work efficiency. Therefore, it is the key work for the development and design of liquid ring vacuum pump and refrigeration compressor to replace the outdated products with high energy consumption and high efficiency.

Liquid ring vacuum pump polishing method

If the surface of liquid ring vacuum pump is equipped with barbs and other defects, it will not only cause harm to the user, but also accumulate dust and aggravate the damage of mechanical equipment. Therefore, the manufacturer will solve this difficulty according to the polishing method before the original packaging of goods in stock.

Flame polishing treatment: the surface of liquid ring vacuum pump is loosened and baked with flame, the fire point is destructive, and the twill and wrinkle on the surface of industrial equipment are removed, but the straightness of the surface of diesel generator will be reduced by this way;

Polishing treatment of polishing powder: high speed friction is carried out on the surface of the diesel generator to remove scratches on the surface of the diesel generator. However, there are many common raw materials in this method, and the manufacturing process is slow;

Acid treatment and polishing: the metal surface of the diesel generator is treated with acid. When this method is used for polishing, not all the striations on the surface of the diesel generator can be removed.

After polishing, the surface of water ring vacuum pump is bright and clean, which is more conducive to the operation process and application of everyone. The common polishing treatment methods are mainly described in several categories. Enterprises can select suitable methods according to their own production and processing details to ensure that the products can work efficiently.