High Vacuum Technology-Vacuum Regimes

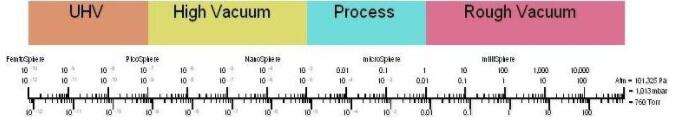

High Vacuum Technology is the science of the removal of all (or nearly all) gases from a chamber, and the measurement and manipulation of the vacuum environment. The applications of vacuum technology are as broad as modern technology itself, ranging from holding workpieces (vacuum chucks) to Thermos flasks, energy saving glass, CDs and DVDs, incandescent light bulbs and cathode ray tubes, medical scanners and chemical analysis tools, to high energy physics research facilities and the development of the next generation of nuclear power (nuclear fusion).The requirements of these technologies on the vacuum environment are equally broad, demanding the application ofa wide range of techniques to achieve them. The absolute pressure, partial pressures of particular residual species and electronic, magnetic and physical effects of the pumps on system processes all need careful attention when designing a system.With pressure requirements for different processes ranging from a few tenths of an atmosphere (vacuum chucks etc.) to less than a trillionth of an atmosphere (eg. surface science applications), and with vastly different sets of physical laws applying, vacuum science is necessarily subcatagorised into a number of vacuum regimes. The pressures of transition from one regime to another are open to some interpretation and can depend on system configuration, but the chart (below) is a guide to what vacuum engineers mean when they talk about rough, process, high and ultra-high vacuum:

Vacuum Regimes

Rough Vacuum: Atm (1000mbar) – 10-2mbarRough vacuum is concerned with the removal of the bulk gas from the system. There are many, many gas molecules in the chamber (right) and these interact with each other according to the laws of thermodynamics in the manner of a viscous fluid. The gases are said to be in ‘viscous flow’. Rough vacuum pumps are therefore fluid flow pumps of the sort familiar to most mechanical engineers.

Process Vacuum: 10-2mbar – 10-4mbarMany vacuum processes occur at a pressure of the order of millionths of an atmosphere. The chamber is first evacuated to high vacuum (see below) and then back-filled with some process gas.

At these pressures interactions between molecules are still significant but the fluid flow characteristics of the gases breaks down and gas collisions with the chamber walls also begin to affect the gases’ behaviour. Now, in addition to the gases flowing through the system, trace contaminant gases are desorbed from the chamber walls. Few pumps are optimised for process pressure operation and a combination of rough and high vacuum pumps (in series) is usually required to obtain the required conditions.

High Vacuum: 10-5mbar – 10-9mbarThe high vacuum regime is dominated by molecule – chamber wall collisions with the mean free path between molecule – molecule collisions being far greater than the dimensions of the chamber. The residual gases bounce around like marbles being shaken in a box and a completely different kind of pump is needed. Rather than literally sucking the gases out of the system, the pump must wait, like a Venus Flycatcher, for gas molecules to enter its throat. High vacuum pumps are therefore ‘statistical capture’ pumps. High vacuum pumps cannot pump atmospheric pressure gas and cannot be exhausted to atmosphere. Rather, they are secondary pumps and require either ‘backing’ or periodic ‘regeneration’ by a rough vacuum pump.

Ultra-High Vacuum: < 10-9mbarWhereas the dominant species in high vacuum is usually water, ultra-high vacuum (UHV) is almost 100% dry and Hydrogen is the most prevelant residual gas. Hydrogen is light and mobile and very difficult to pump, requiring specialised UHV pumps and reducing the gas load from the chamber walls is paramount.