Liquid ring vacuum pump applied in sugar plant

Sugar is a necessity of human life, but also an important base for the food industry and the downstream raw materials industry, food, cotton and oil.

70s sugar factory is a piston-type vacuum pump, piston-type vacuum pump because of large fuel consumption, vibration, easy to bad and other shortcomings. Later, the sugar factory water jet pump to produce negative pressure to work instead of piston vacuum pump, which has low efficiency, high power consumption, while water consumption is very large, causing pollution to the environment, need to pay a huge pollution control costs. In recent years, Shanghai EVP company through various aspects of the sugar industry to use the characteristics of research, according to the requirements of sugar vacuum filtration plant requires large amount of crystallization and crystallization, boiled sugar requirements of high vacuum characteristics, has been designed to produce a new generation of sugar industry Vacuum system. The system includes 2BE, 2BV liquid ring vacuum pump, condenser and other equipment.

Liquid ring vacuum pump’s advantage compared to piston-type vacuum pump and water jet pump in the sugar plant:

1. Reduce the cost of water and pollution, it is only 1/3 of the water jet condenser (air jet).

2.Compared with the water jet condenser and reciprocating pump, the Liquid ring vacuum pump is designed to be simple and does not need replacement parts and lubricant filling. The high suction capacity can rapidly recover the vacuum (only a few minutes), saving 30% energy.

3. Running without wear, no maintenance, long-term trouble-free operation.

4. Easy to install and operate

5 get a higher and more stable vacuum, can be used for high altitude vacuum. For example, in Yunnan Province, China (with an average altitude of more than 2000m), local pressure and vacuum reach -0.085Mpa (gauge), fully meeting the technical requirements.

The flow sheet of refined sugar is as below:

Liquid ring vacuum pump mainly applied in four aspects of sugar industry: co2 preparation, filtration, evaporation, crystallization.

CO2 preparation:

In the process of clean juice , usually choose carbonization process, with reliability, safety, stable operation, lower cost is unmatched by other products. This process needs to add co2, so need to prepare Co2.

The CO2 compressor not only compresses, but also keeps the gas clean.The compressor is completely oil-free and insensitive to the ingress of solid particles. The compressor disc ensures that the gap between the rotor and the impeller is large enough to prevent the CO2 gas Inhalation of lime / soot and other disc wear and tear.These impurities will not be discharged with the CO2 gas to ensure the collection of CO2 gas cleaning.

Filtration:

The vacuum suction filter uses vacuum pressure to check the mud and juice together, the mud layer is adsorbed on the drum surface of the suction filter, and the juice passes through the partition of the drumhead, the partition board is sucked into the inner tube of the transfer tube, Exclusion of filtration juice, adsorption filter in the filter surface filter rotation, turn left to leave the vacuum zone.

The vacuum pump / compressor can withstand accidental water shocks. The exhaust port on the distributor plate is dimensioned and pressure relieved (over-compressed) so that the pump can withstand the impact of water from the filter separator or condenser without affecting the vacuum degree.

Evaporation:

The key process of evaporation is to discharge non-condensable gases and reduce the color and intensity of sulphite. Evaporation cans and sugar cane juice are equipped with ammonia discharge pipe non-condensable gas. Water ring vacuum pumps are superior to jet condensers in pumping non-condensable gases, increasing vacuum, accelerating fuel tank throughput, reducing evaporator color, reducing cure strength, sulfur in sugar, and yellowing of finished products. 2BE, 2BV Series Water Ring Vacuum Pumps and Closed Circulation Units are suitable for pumping gas and steam with suction pressures up to 33 mbar abs. When using oil as the working fluid (oil ring vacuum pump), suction pressure up to 6.7mbar abs. (99.3% vacuum), can completely replace the reciprocating vacuum pump. 2BE, 2BV series stainless steel vacuum pump can be used for demanding high corrosion resistance and clean the occasion.

Crystallization:

The main task of boiling is to concentrate the syrup (or molasses) in a boiling jar supersaturated, and to separate the fine candies from the acceptable crystals and slurries. After crystallization and removing the mother liquor by a centrifuge, fine rock sugar is obtained. The most important thing in this process is to ensure that there is sufficient vacuum and boiling stability to evaporate, while the main factor for stability is thermal cycling water. Complete sets of vacuum system Jing Gong in the boiling process to deal with the issue of vacuum is the best way to cool the loop effectively control the water temperature, fully meet the high vacuum boiling evaporation requirements

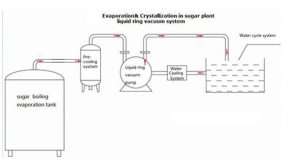

liquid ring vacuum system diagram of evaporation& crystallization in sugar plant is as follows:

According to the requirements of high vacuum and pumping corrosion, Shanghai EVP has developed a variety of products to improve the stability and reliability of the vacuum pumping system. All flow channel components are made of high-quality 304 material, – spraying, PTFE coating, polymer coating and other corrosion methods to improve corrosion resistance. Impeller blade root and side stiffeners using high-temperature solid welding method to improve blade strength, effectively prevent the high vacuum caused by long-term operation of the impeller cracks. Side stiffeners interrupting end faces, scraping objects between port plate and end face to prevent foreign body scaling between impeller and port plate, and port wear Air protection inside vacuum pump for evaporative and crystallization processes Design avoidance Due to long-term cavitation caused by the impeller cracks.

Tags:Liquid ring vacuum pump, water ring vacuum pump system

Edited by Nancy Zhang / EVP vacuum solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)