Single-end mechanical seal flushing program

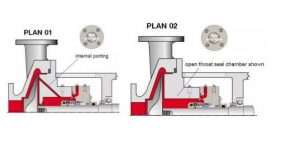

PLAN 01 (Single-sided self-rinse)

Description: The internal circulation from the outlet of the pump to the seal. Its operation similar to PLAN11.

Reason: sealed chamber cooling; sealed chamber exhaust.

Application: Single-end seals more be used for clean the transported fluid of viscous and easy to cure case at room temperature.

Maintenance: flushing can not directly flush the sealing surface; It must ensure adequate circulation; machine seal cooling can not be over.

PLAN 02 (sleeve cooling with heat)

Description: Sealed chamber without flushing fluid circulation.

Application: Large holes under room temperature operation, open sealed chamber; Cooling sleeve sealing chamber under high temperature operation.

Cleaning fluid: dry seal upright, Jacking mixer, blender.

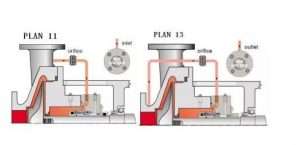

PLAN 11 (Self-Flushing)

Description: Mechanical seal flushing start from the pump outlet to the limiting orifice plate.

Reason: cooling of the sealed chamber, exhaust of the horizontal sealed chamber, increasing the pressure of sealed chamber and the critical space of the fluid vaporization.

Application: Usually it used to clean non-polymeric fluids; the most common flushing solution for general condition equipment.

PLAN 13 (Backwashing)

Description: The Secondary Circulation from the sealing cavity to the Inlet of the pump through the flow limiting hole Plate. (Standard washing Scheme for Vertical pumps)

Reason: vertical pump seal chamber uninterrupted exhaust gas, sealed chamber heat removal.

Application: Vertical pumps, sealed chamber pressure greater than the inlet pressure, it mixed with fluid of medium-sized solid at room temperature, it’s non-polymeric fluid.

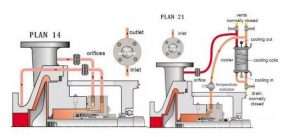

PLAN 14 (Forward & Reverse Flushing)

Description: Rinse the machine seal from the pump outlet, then recirculate to the pump inlet through restricted flow orifice, it’s combination of plan 11 and 13.

Reason: vertical pump seal chamber continuous exhaust, seal chamber heat removal, increasing the pressure of sealed chamber and the critical space of the fluid vaporization.

Application: Vertical pumps, room temperature, clean non-polymeric fluids.

PLAN 21 (self-flushing with cooling)

Description: From the pump outlet through the orifice plate and cooler to rinse machine seal, it’s plan 11 add the cooler to increase the heat removal capacity.

Reason: Mechanical seal cooling, abate fluid temperature and reduce coking.

Application: High temperature, Hot water clean that below 350 ° F (177 ° C) above 180 ° F (80 ° C), non-polymeric.

Tags : liquid ring pump

Edited by Jinny Zhang / EVP vacuum solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)