Pump in the oil and gas industry

Types of pumps in the oil and gas industry – upstream, midstream, downstream

Different types of pumps in the oil and gas industry industrial pumps are essential equipment for all stages of oil and gas operations. Basically, they help transfer process fluid from one point to another.

For example, a pump can be used to transfer crude oil from a storage tank to a pipe, while a mud pump is used to circulate drilling mud into the annulus of the drill bit before returning to the tank for repurification.

In oil and gas operations, process fluids range from easy to difficult. Depending on the nature of the substance you are transferring and the flow rate you need, you will need a pump that fits your needs.

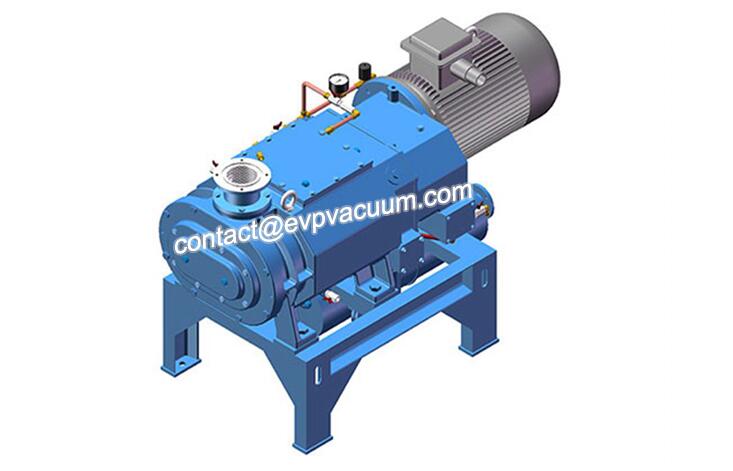

Next look, suitable for the oil and gas industry screw pump

Oil, natural gas industry for screw pump provides a broad application space. In addition to single screw pump, more familiar is, whether on land or at sea, multi-screw displacement pump is also widely used in this field.

Compared with other rotary positive displacement pumps, such as centrifugal or reciprocating pumps, screw pump has superior design:

◆ high/low viscosity liquids can be processed simultaneously

◆ higher efficiency, lower energy demand

◆ the shear damage is the least when the oil-water mixture is emulsified with crude oil

◆ the pumping flow is independent of the back pressure

◆ good self-priming ability

◆ stable, no vibration, low noise operation

◆ gas-containing liquid (the multiphase mixed transport pump can handle 100% gas-containing medium)

◆ the flow rate can be easily controlled through frequency converter

Main considerations for pumps in oil and natural gas applications

At every step of the extraction, transportation and refining processes, hydrocarbon applications tend to be demanding, requiring equipment of the highest quality and reliability.

Pumps in the oil and gas industry often need to operate under extreme environmental conditions, depending on the particular application, which may include extremely high temperatures and pressures or extremely low pressures and temperatures.

The pump must be made of a material that can withstand its working conditions and must not react with any chemical to be exposed.

Material selection is usually governed by protection against corrosion, oxidation, and accumulation of pump assemblies. Some pumps must also be able to handle abrasive or volatile materials.

In general, pumps and other equipment must be highly specialized for their desired applications and must also meet various standards.

For example, a process pump that handles oil and natural gas must generally meet the API 610 standards for pumps that handle hydrocarbons.

Since these process pumps must handle hydrocarbons at extremely high pressures and temperatures, and if accidentally released, there is a risk of explosion, the integrity of the pump shell is a priority in their design and construction.

Pump failures in oil and natural gas applications can incur significant financial costs and safety and environmental hazards, which make pump and system reliability and safety extremely important.

In addition to meeting load requirements and flow rates, other important considerations in oil and gas applications may include metering accuracy, operational flexibility, efficiency, and maintenance requirements.

In some cases, such as pumps that may need to move between upstream Wells, portability may also be an important consideration.

These are just some of the many factors that must be considered when specifying pumps and associated equipment for oil and gas applications.

In an industry where there is little room for error, quality, suitability for use and reliable pumping equipment and systems are essential for efficient, safe, compliant, economical and efficient operation.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)