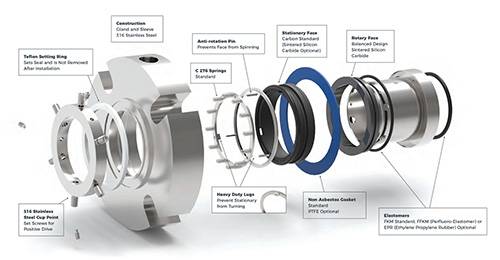

Roots blower mechanical seal

As a contact seal, the mechanical seal of Roots blower has good sealing effect; as a face seal, it has no wear on the shaft. At the same time, with the help of the sealing material, the self sealing liquid is usually used for long lubrication period. However, the structure is more complex, the accuracy requirements are high, the price is relatively expensive, and the maintenance is not very convenient. Generally it refers to the occasion where the sealing requirements are high and other forms of sealing can not meet the requirements.

The mechanical seal of Roots blower is lubricated and cooled by sealing fluid. Sealing fluid is generally turbine oil. When oil is not allowed to be used as sealing fluid, clean water or other suitable medium can also be used as sealing fluid. When working, it is necessary to use the pumping system or self circulation system to make the sealing liquid circulate in the sealing cavity.

When roots blower is running, the moving ring of mechanical seal rotates along with the shaft, which makes the oil in the seal chamber flow along the direction and produces centrifugal force. Because of absorbing the friction heat of the seal face, the temperature of the oil in the seal cavity is higher than that in the circulating oil tank. Therefore, after the oil flows into the sealing chamber from the circulating oil tank, its volume expands, its specific gravity becomes smaller, and buoyancy is produced. Due to the action of centrifugal force and buoyancy force, the relative displacement of oil particles is caused, so as to achieve the purpose of convective ring heat.

In addition, at the inlet of the upward oil pipe, the oil flows upward automatically after changing the flow direction due to the extrusion of the brake mechanism. After the oil is cooled properly in the circulating oil tank, it flows into the seal cavity through the downward oil pipe, continuously carrying away the friction heat of the seal end face, and making the friction pair in a good lubrication state.

The main causes of mechanical seal failure of Roots blower are as follows:

(1) The quality of spare parts and the manufacturing accuracy of components can not meet the requirements. From the mechanical seal point of view, the cylindrical pin is rough, which can not guarantee that the moving ring can timely compensate the deformation under the action of spring force. Although it has been polished before installation, its accuracy can not be guaranteed.

(2) Design defects, in the compressor mechanical seal design process, there are also problems, this mechanical seal is a double face mechanical seal, the outside of the dynamic and static ring in the long-term operation process, roots blower unit internal can not provide sufficient lubrication, is also the cause of mechanical seal damage.

(3) Process conditions: the process conditions of the sealing ring were not considered in the processing of the sealing ring, and the actual working conditions were not considered in the processing process of the static seal O-ring made by the manufacturer, which caused the leakage of the mechanical seal.

Disassembly and assembly of Roots blower seal:

The removal steps of mechanical seal are as follows:

(1) Before disassembly, the mechanical seal should be pressurized (test pressure 1kg), to confirm whether there is leakage, record the leakage data, and confirm the quantity of replacement;

(2) Remove the special bracket of the mechanical seal from the frame and install it on the mechanical seal;

(3) Remove the fixing screws;

(4) Eject the mechanical seal evenly and mark the installation position.

The installation steps of mechanical seal of Roots blower are as follows:

(1) Confirm that the rotor piece is in T-shaped state;

(2) Clean the mechanical seal surface, replace the seal ring, and coat the auxiliary seal with thin oil;

(3) Use a marking pen to lead out the keyway position on the journal;

(4) The special support of Roots blower is installed on the mechanical seal, and the screw is not installed on the dynamic seal;

(5) Rotate the dynamic seal to make the key groove on the dynamic seal correspond to the keyway position on the journal;

(6) Diagonal installation guide bolt (special bolt) of Roots blower;

(7) The nuts are brought in evenly;

(8) Drive in the connection key;

(9) Install the fixing screw of mechanical seal, and coat the screw with medium strength anaerobic adhesive;

(10) Remove the special bracket.

Because the mechanical seal structure of Roots blower is complex and the disassembly is inconvenient, the mechanical seal assembly is particularly important. If the mechanical seal of Roots blower is damaged and leaked for many times in the process of putting into operation, the main reason is that the inlet filter is blocked, which makes the differential pressure increase, and the equipment produces vibration, which eventually leads to the mechanical seal damage. In addition to strengthening the filtering device, whether the mechanical seal is well assembled is also an important factor affecting the use of the seal.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)