Roots blower of high temperature causes

The temperature of Roots blower is normal. Generally speaking, the higher the pressure of Roots blower, the higher the temperature, the higher the speed, the higher the temperature. Normally speaking, the increase of 20 kPa will increase 1.1 degrees centigrade, and the rotation speed will increase by 0.9 degrees centigrade. One is that the larger the fan, the higher the temperature.

Different manufacturers produce the same roots blower why the temperature will be different, depends on the gap adjustment, the quality of the bearing, and so on!

The normal working temperature range of Roots blower is 30-90 ℃, and the outlet temperature of Roots blower is proportional to the pressure.

Calculation method of body temperature of Roots blower: room temperature + 10 ℃ temperature rise per 1000mm water column (within this range, it is normal value, if it exceeds, it means that the temperature of Roots blower is too high). The higher the temperature of Roots blower, the more serious the impact on the life of the blower.

Roots blower temperature is too high, can not find the cause of fan temperature is too high, take a look at these.

1. The inlet is blocked and the inlet of Roots blower is blocked, which leads to the temperature rise of Roots blower.

2. Belt slippage will cause friction heat between belt and pulley, resulting in a large amount of heat, resulting in fan temperature rise.

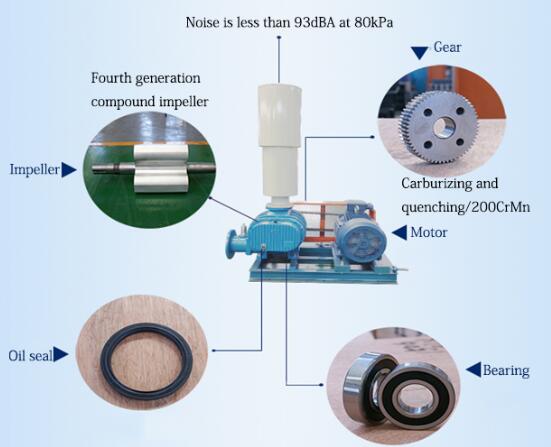

3. There are many internal damage, such as impeller friction, casing impeller friction, gear friction, gear friction will also produce a lot of heat.

If the temperature of Roots blower is too high, it can be checked according to the above three points. Many problems are caused by interlocking, which will eventually be attributed to a certain point. For example, bearing wear causes friction between impellers, and then generates a lot of heat, which affects the operation of the whole fan.

EVP vacuum pump manufacturer tips: Roots blower if the internal damage will be accompanied by other faults, such as noise, abnormal vibration, etc.

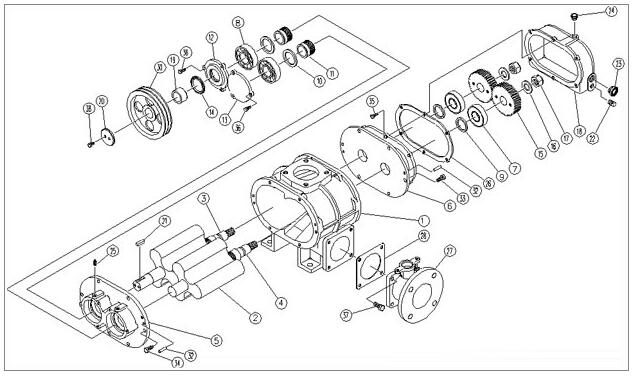

The following points should be paid attention to when disassembling roots blower: different structure forms of Roots blower lead to different disassembly methods. However, before disassembly, attention should be paid to the following points:

1. Before disassembly, the assembly clearance between the components to be disassembled should be measured. For the assembly position of the key parts, such as the synchronous gear of the blower, should be recorded to avoid errors during reassembly.

2. The dismounted joint surface cushion and adjusting gasket shall be properly kept. The assembly position shall be recorded and the thickness shall be measured as the basis for assembly.

3. For some components with high assembly accuracy, such as the gear wheel and gear ring of Roots blower synchronous gear, if the gear ring is not damaged, do not easily remove the bolt to knock out the pin, because this assembly accuracy directly affects the clearance of each part of the blower.

4. For different parts, appropriate tools should be selected for disassembly, so as to avoid damaging parts, affecting assembly quality and even causing equipment not to run normally.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)