Roots Blower Used in Chemical Fertilizer Industry

At present, Roots blower is more and more widely used, and it is also popular in fertilizer plants. It can improve the efficiency of chemical fertilizer plants, and can be in the form of fluids, drying particles and gases. Various process fans are used for dust removal and flue gas extraction, granulation and mixing, air pressure and circulation, pneumatic transportation of chemicals or additives, etc.

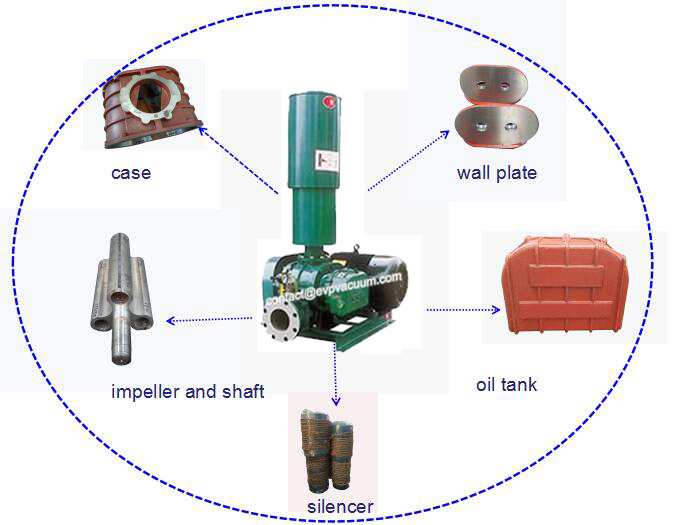

Roots SSR Series Horizontal Rotary Blade Blower, Model SSR 50-200, Carbon Steel. With motors, silencers and filters. Frame installation.

Product display

Technical details:

The speed of SSR-50 Roots blower is 1100-2120 rpm. The flow rate is 0.99-2.19 cubic meters per minute, the pressure is 3000 mmH 2 O., the power is 0.78-1.96 kilowatts, and the weight of the single machine is 100-9000 kilograms.

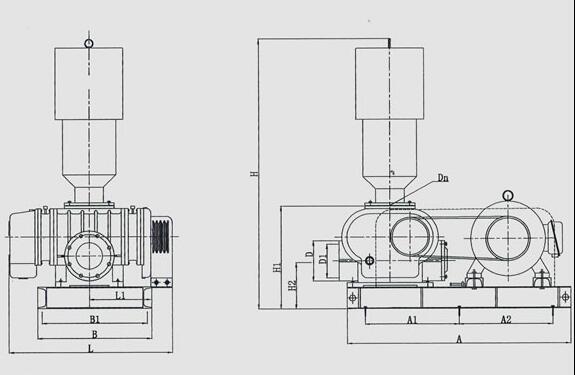

Installation dimension

Operation instructions

1. The inlet temperature of the conveying medium should not be greater than 40 C.

2. The content of particles in the medium shall not exceed 100 mg / m3 and the maximum size of particles shall not exceed half of the minimum working gap.

3. Bearing temperature should not be higher than 95 and lubricating oil temperature should not be higher than 65 during operation.

4. Use pressure shall not be higher than the range of boost prescribed on the nameplate.

5. The clearance between impeller and casing, impeller and side plate, impeller and impeller of Roots blower has been adjusted when leaving the factory. The clearance should be guaranteed when reassembling.

6. When Roots blower is running, the oil level of the main tank and the auxiliary tank must be between the two red lines of the oil level meter.

Talking about the use and maintenance

The use requirements of Roots blower are that the temperature of the air inlet medium transported should not be higher than 40 C, the content of impurities in the medium should not be greater than 1000mg/m_and the maximum size of particles should be less than 0,1mm. When using boost, it must not exceed the rated boost value specified on the nameplate of the blower. Because of the special structure of Roots blower, there are many differences in operation requirements with other blowers, which must be paid attention to.

start-up

Roots blower should make the following preparations before starting up.

(1) Open intake control valve, exhaust control valve and bypass pipe completely;

(2) Check whether the air filter in the air inlet is unblocked and whether the filter inlet is fully opened;

(3) Check whether the support of pipes, valves, mufflers and air filters is stable or not, and no load shall be applied to the housing;

Roots blower has been on the market for a long time, its performance is stable and reliable, and its quality is excellent.Widely used in power plants, sewage treatment systems, chemical fertilizer plants, pneumatic conveying systems, aquaculture, cement plants, paper mills, food factories and so on.