Rotary vane vacuum pump in paper industry

The most common vacuum equipment in the vacuum system of paper making is rotary vane vacuum pump. By introducing its development history, working principle, structural characteristics and the application characteristics of rotary vane vacuum pump in paper industry, this paper summarizes its advantages, hoping to provide references for the relevant technical personnel in the paper industry when choosing vacuum equipment. At present, in the paper industry, water ring vacuum pump (compressor) is a product with high energy consumption and low efficiency. Therefore, it is necessary to re-select suitable vacuum equipment. Rotary vane vacuum pump is the most commonly used equipment in papermaking vacuum system, which is well known to technicians in papermaking industry.

Rotary vane vacuum pump development history

Among all kinds of vacuum pumps, rotary vane vacuum pumps are the most widely used in paper mills, one of the most important types of vacuum pumps, and also the most rapidly developing type of vacuum pumps with functional structure.With the continuous improvement of the technological performance of rotary vane vacuum pump, industrial robots, microelectronics, computers, intelligent and image sensing technology are widely used in the production system of pump industry. In the future market, the research and manufacture of rotary vane vacuum pump will develop towards the direction of high speed, multi-function and intelligent control, and automation. And integration will become the development direction of rotary vane vacuum pump in the future.

Rotary vane vacuum pump working principle

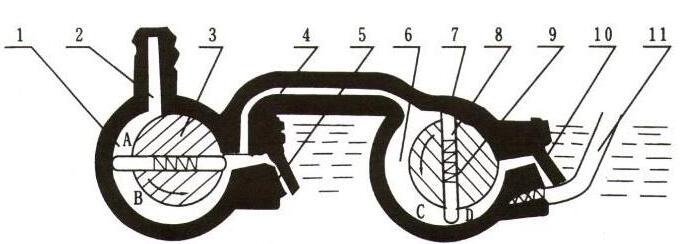

The rotary vane of rotary vane vacuum pump divides the crescent space enclosed by the rotor, pump chamber and two end caps into three parts: A, B and C. When the rotor rotates in the direction of arrow, the volume of space A connected with the suction port increases gradually and is in the process of suction. The volume of the space C connected with the exhaust port is gradually shrinking, and it is in the exhaust process. The volume of B in the middle space is also gradually decreasing, and it is in compression process.

Because the volume of space A increases gradually (i.e. expands), the pressure of gas decreases, and the pressure of gas outside the inlet of the pump is stronger than that inside space A, the gas is inhaled. When space A is isolated from the suction port, that is to say, when it moves to space B, the gas begins to be compressed, the volume gradually reduces, and finally communicates with the exhaust port. When the compressed gas exceeds the exhaust pressure, the exhaust valve is pushed open by the compressed gas, and the gas is discharged into the atmosphere through the oil layer in the tank. By continuous operation of the pump, the purpose of continuous pumping is achieved. If the exhausted gas passes through the airway and transfers to another stage (low vacuum stage), it is pumped out by the low vacuum stage, and then compressed by the low vacuum stage and discharged into the atmosphere, a two-stage pump is formed. At this time, the total compression ratio is borne by the two stage, thus raising the limit vacuum degree.

Rotary vane vacuum pump structural characteristics

Rotary vane vacuum pump is mainly composed of pump body, rotor, rotary vane, end cover, spring and so on. A rotor is eccentrically installed in the cavity of the rotary vane pump. The outer circle of the rotor is tangent to the inner surface of the pump cavity (there is a small gap between them). Two rotary vanes with springs are installed in the rotor groove. When rotating, centrifugal force and spring tension keep the top of the rotor in contact with the inner wall of the pump chamber. Rotor rotation drives the blade to slide along the inner wall of the pump chamber.

Rotary vane vacuum pump application characteristics

Modern paper machines use vacuum to help paper dehydration, so the vacuum system is an important part of a paper machine. There are many vacuum components with different vacuum degree on a paper machine which need to be connected to the vacuum system. If a rotary vane vacuum pump is used to set up a vacuum system, it is often used to combine some close points of vacuum degree and select several rotary vane vacuum pumps to set up a vacuum system according to different vacuum degree. The use of vacuum pumps is independent, and there will be no interference or chain reaction between different vacuum pumps. Under the existing technical conditions, the comprehensive performance of rotary vane vacuum pump is better than others, so the application of rotary vane vacuum pump in papermaking industry occupies a dominant position.

If you want to know more about our vacuum pump products, or if you want to consult the rotary vane vacuum pump application please leave a message or send us an email at contact@evpvacuum.com

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)